DE08TS Diesel Engines Maintenance

Fuel injection pump

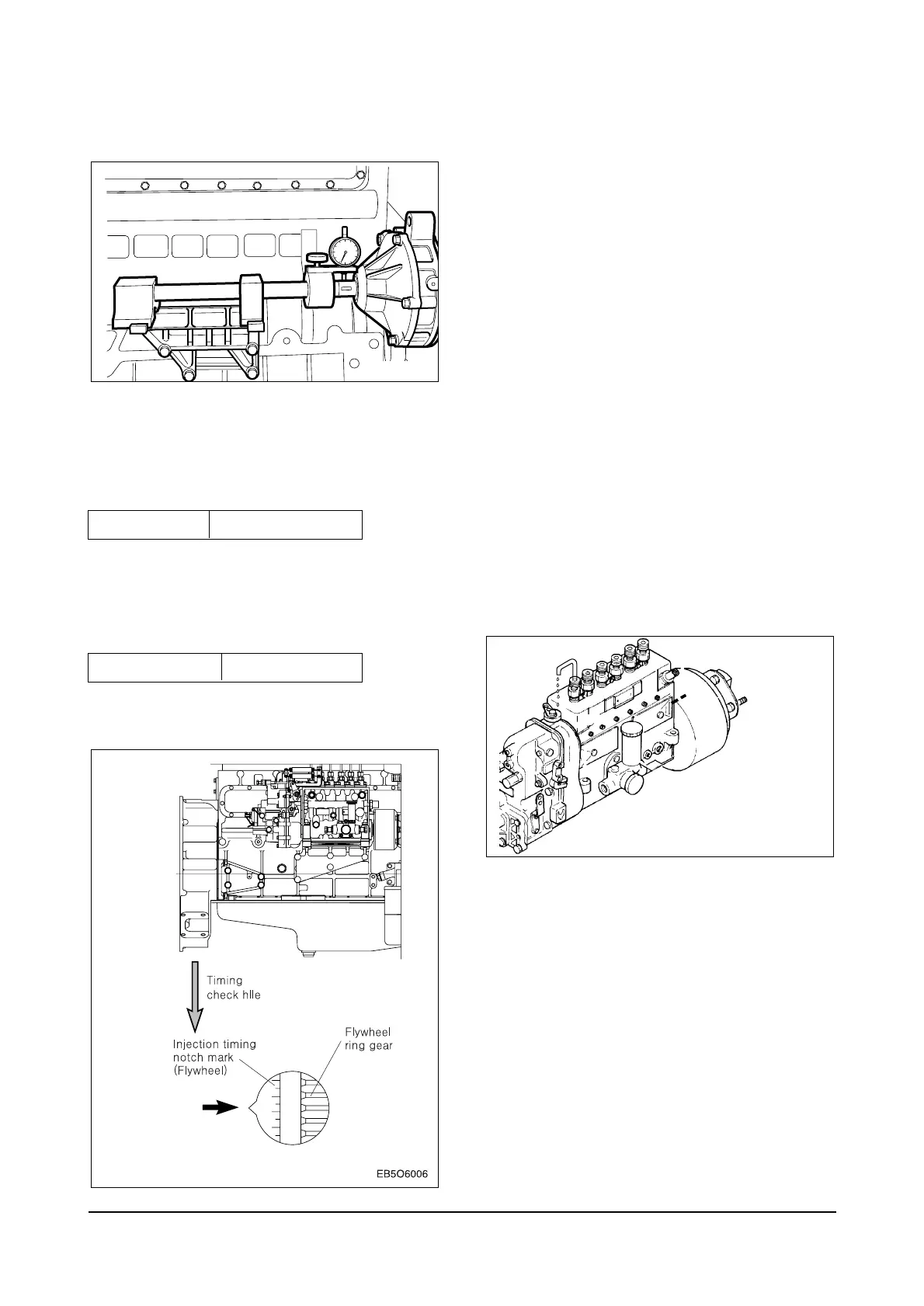

1. Install the injection pump bracket in the cylinder

block.

2. After measuring the amount of run-out with an

alignment setting jig, disassemble the bracket,

adjust the shims, then reassemble it.

3. Mount the top/bottom adjusting shims in the brack-

et and then mount the fuel injection pump.

4. Tighten the fixing bolts in a diagonal sequence to

specified torque.

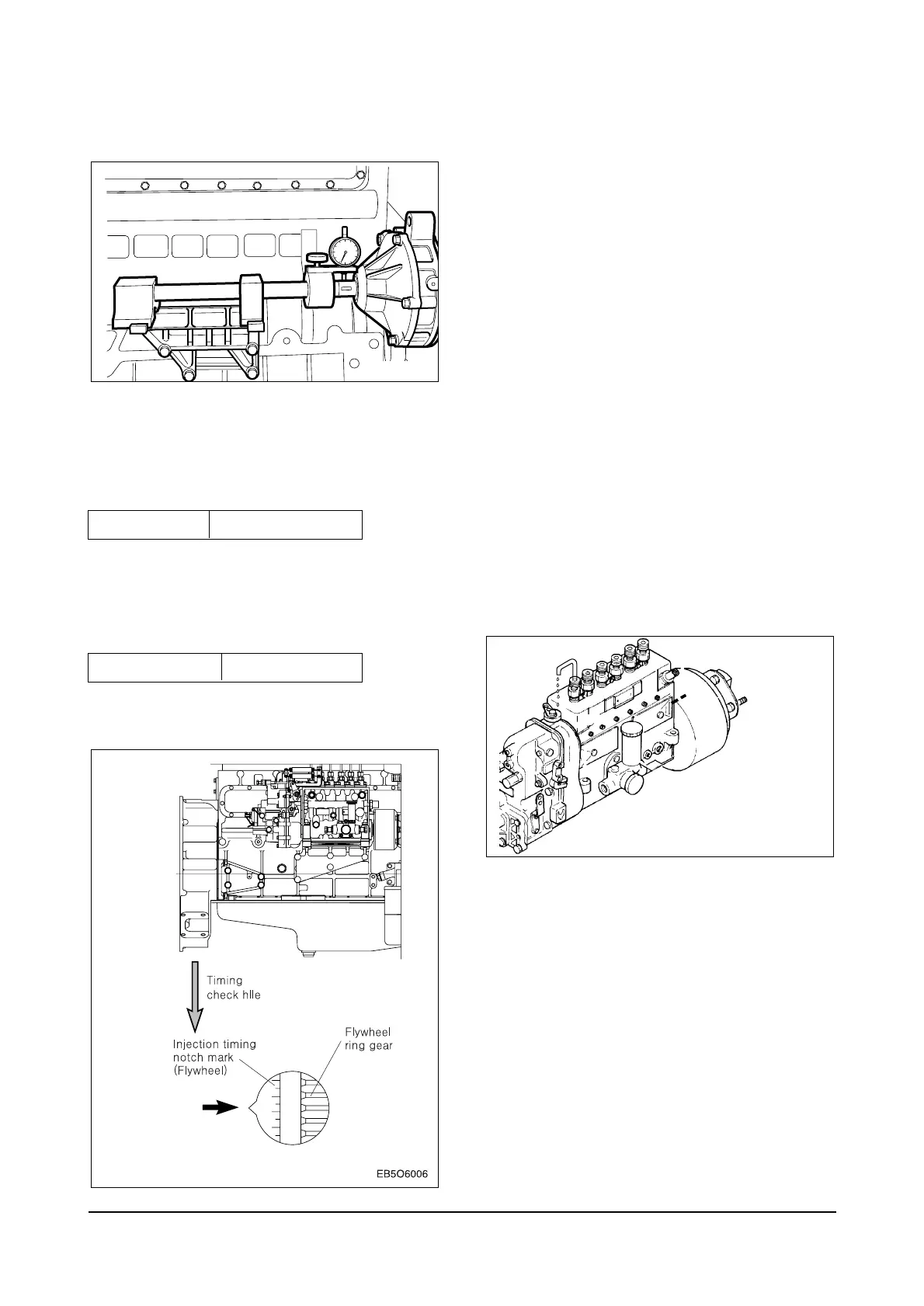

<Injection Timing Adjustment>

5. Bring the piston of #1 cylinder to the compression

TDC (OT) by turning the crankshaft. Again, turn

60° in the reverse direction of engine rotation.

6. Disassemble the fuel injection pipe that connect

the fuel injection pump and #1 injection nozzle.

7. Disassemble the fuel injection pump delivery valve

holder, and after removing the valve and valve

spring, again assemble the valve holder and then,

on it assemble the pipe of “U” shape on it.

8. Operating the priming pump of supply pump, turn

the crankshaft slowly in the direction of engine

rotation until the fuel will drop at the rate of a drop

for 6 ~ 8 sec.

9. Confirm then whether the indication point at the

flywheel housing inspection hole and the engraved

specified injection angle are coincided or not, and

if the injection timing is not correct, adjust as fol-

lows.

a. As above adjusting method, Please coincide

the indication point( ) at the flywheel housing’s

inspection hole with the flywheel’s inspection

angle.

Fuel injection timing : BTDC 9˚

b. Loosen the drive gear fixing bolt of injection

pump a bit.

c. After turning slowly the coupling of injection

pump until the fuel will drop from #1 plunger at

the rate of a drop for 6 ~ 8 sec., tighten the dri-

ving gear fixing bolt of fuel pump.

EAMD107I

57

Torque 4.4 kg

•

m

Run - out 0.2 mm or less

Loading...

Loading...