DE08TS Diesel Engines Maintenance of Major Components

Oil pump

1. Disassembly

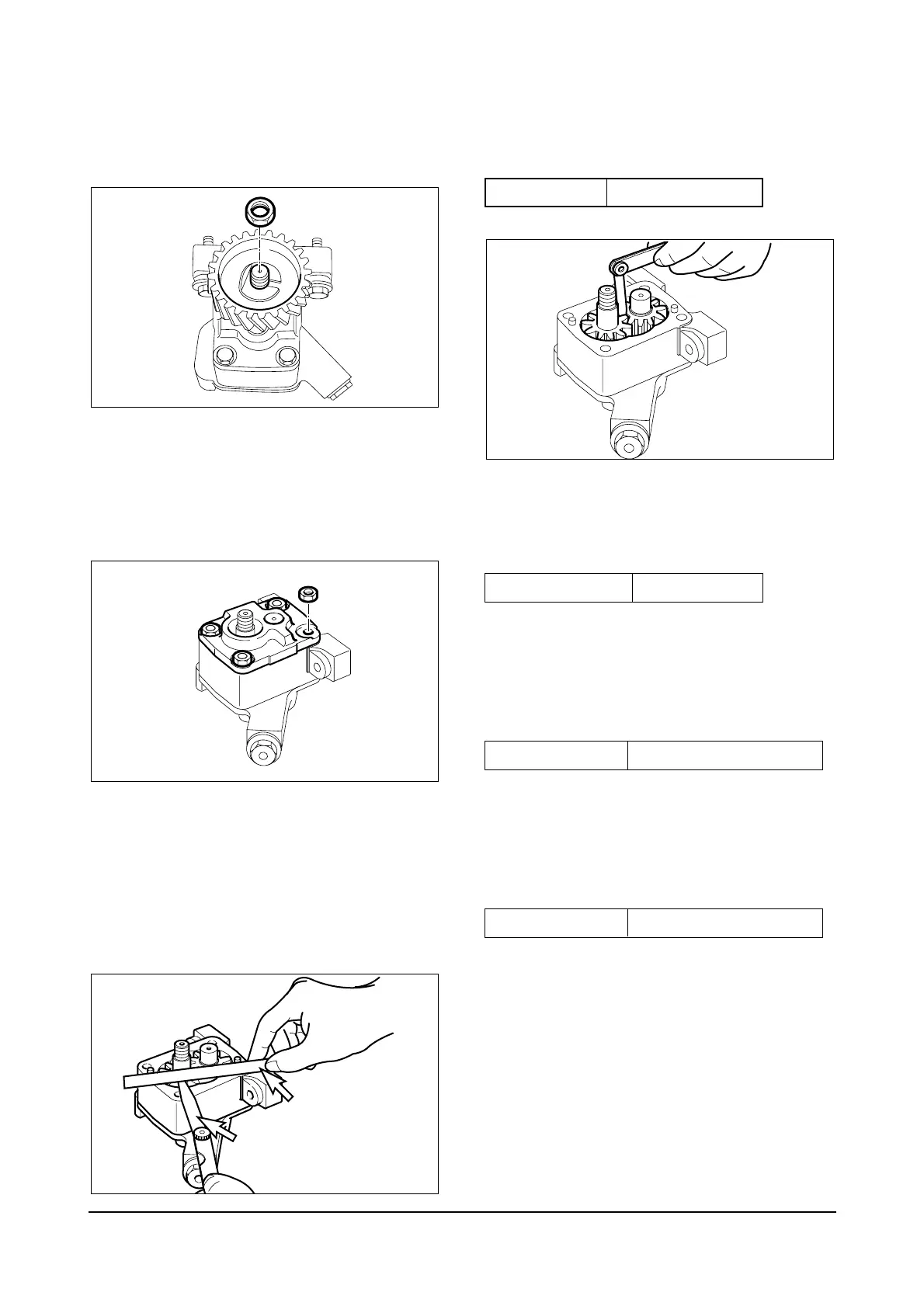

a. Disassembly of oil pump drive gear

• Unscrew the screw and disassemble the oil

relief valve.

• Unfold the washer for the oil pump drive gear

fixing nut and remove the nut.

• Disassemble the drive gear.

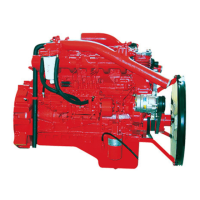

b. Remove the oil pump cover fixing nuts and dis-

assemble the oil pump cover.

The oil pump cover is fixed with the two dowel

pins.

c. Disassemble the drive gear and driven gear.

2. Inspection and correction

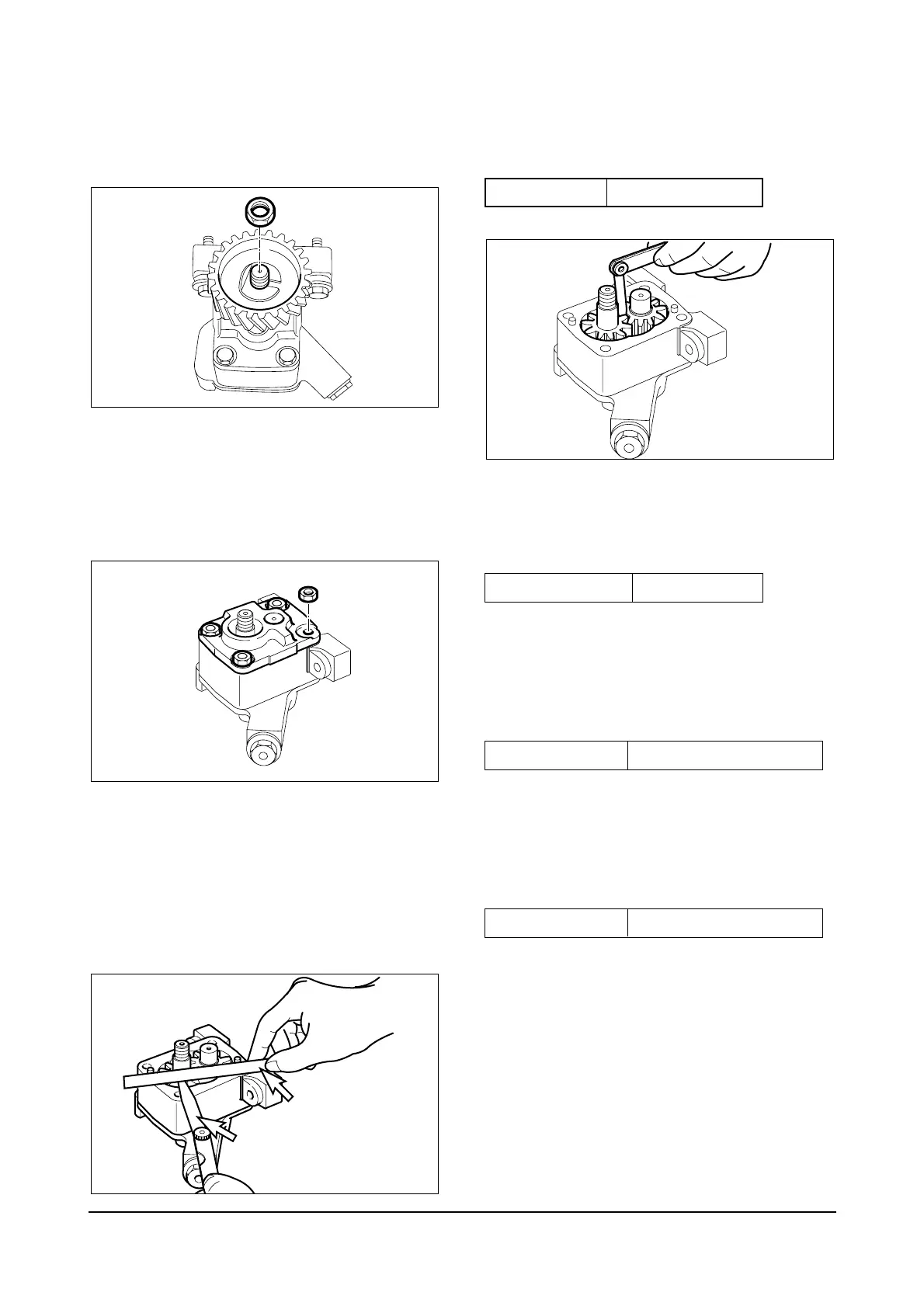

a. With steel rule and feeler gauge, measure the axial

end play of the oil pump gear. Replace if the mea-

sured value is beyond the limit.

b. With a feeler gauge, measure the amount of back-

lash between the oil pump drive gear and driven

gear. Replace if the measured value is beyond the

limit.

c. Measuring clearance between drive shaft and

bushing

• Measure the outside diameters of the drive shaft

and driven shaft, and replace if the measured val-

ues are less than the limit (N16.95mm)

• Measure the inside diameter of the pump body

bushing to determine the clearance between the

bushing and shaft, and compare the measured

value with the standard value to determine

whether to replace or not.

3. Reassembly

a. For reassembly, reverse the disassembly

sequence.

EQM4008I

Steel plate

Feeler gauge

EQM4007I

EQM4006I

73

End play limit

0.025 ~ 0.089 mm

Backlash limit 0.50 ~ 0.64 mm

Standard

N

16.95 ~

N

16.968 mm

Clearance 0.032 ~ 0.077 mm

Loading...

Loading...