DE08TS Diesel Engines Maintenance

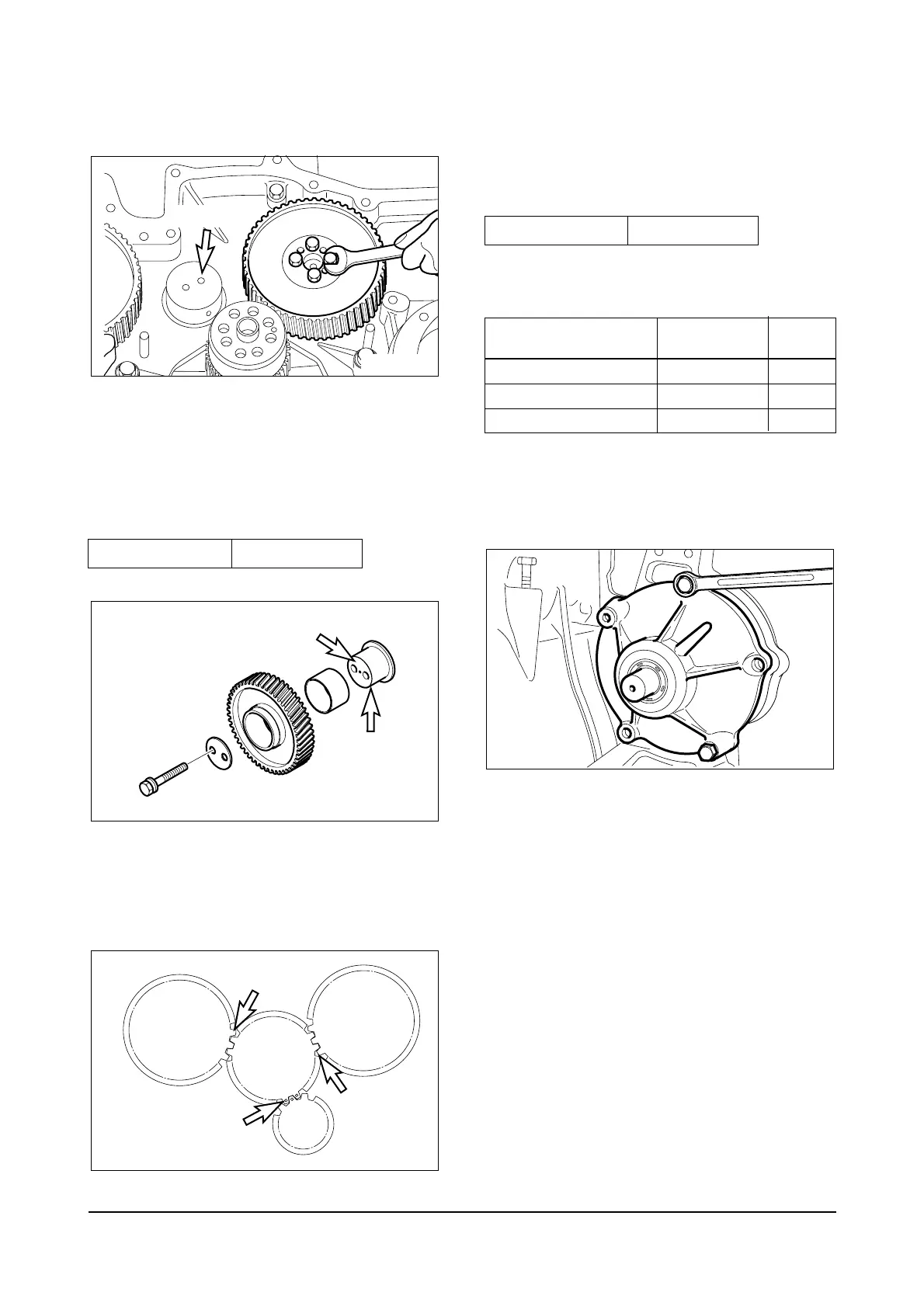

Timing gear and idle gear pin

1. Install the oil pump idle gear onto the No.7 bearing

cap.

2. Install a thrust washer over the camshaft and

assemble the cam gear by aligning it with

camshaft dowel pin. Tighten the cam gear assem-

bling bolts to the specified torque. (Zigzag

method)

3. With the oil port on the idle gear pin facing the

cylinder block, install the idle gear pin.

4. Idler gear pin with oil hole is assembled toward

cylinder block.

5. Install the idle gear by coinciding the marks

impressed on the crank gear, cam gear, fuel injec-

tion pump drive gear, and idle gear.

6. Install a thrust washer on the idle gear and tighten

to specified torque.

7. Check and adjust the amount of backlash between

gears using a feeler gauge.

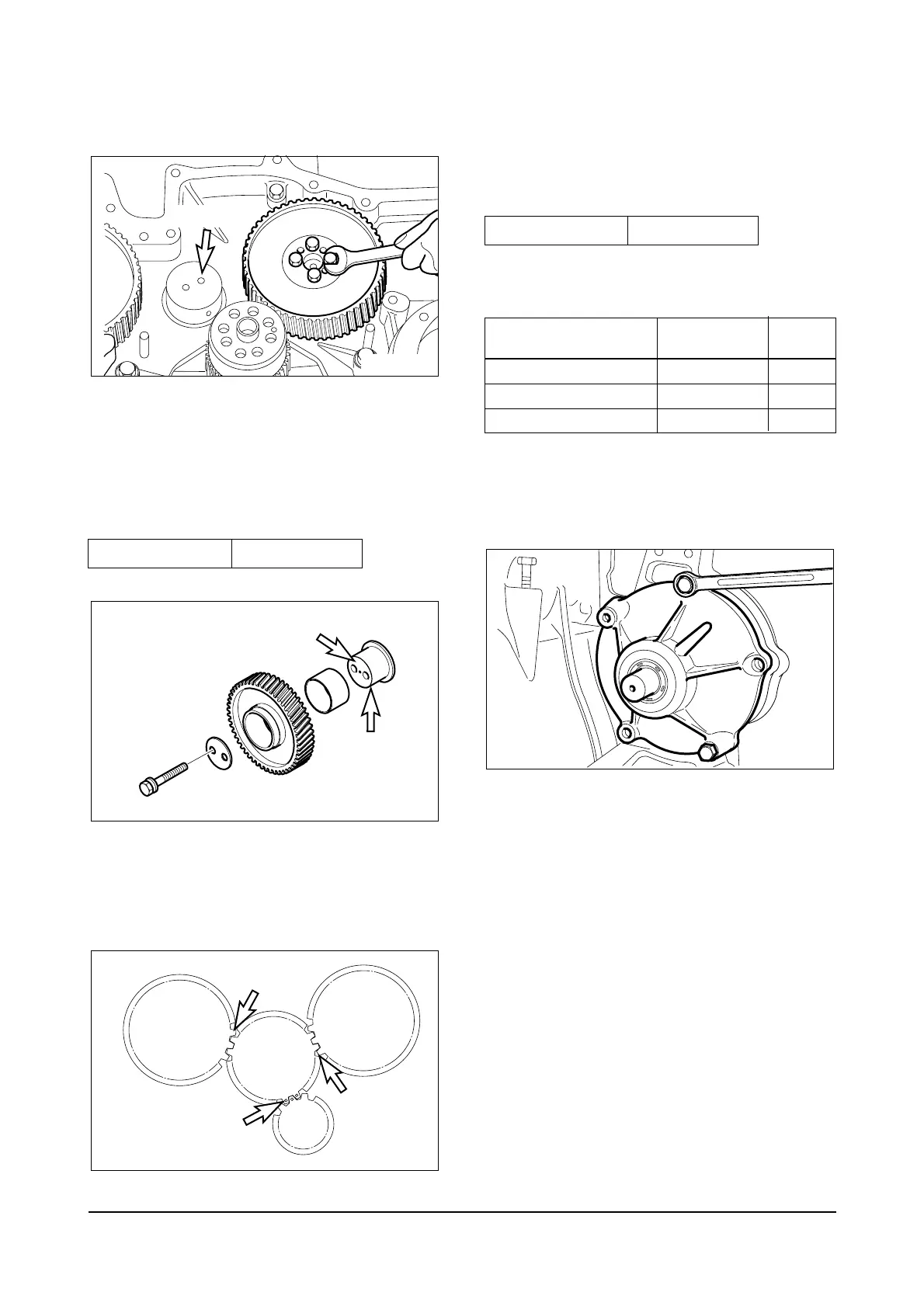

Injection pump flange

1. After assembling the fuel injection pump gear to

the idle gear, tighten the assembling bolts of the

injection pump flange.

2. Mount gasket by aligning the bolt holes with the

pin holes on the bearing housing.

3. Turning the flywheel, adjust the pointer to the posi-

tion of the engraved scale.

4. After adjusting the injection timing of fuel injection

pump drive gear, tighten the fixing bolts in the

direction of fuel injection pump.

EA9M3015

Fuel injection

pump drive gear

Idle gear

Camshaft gear

Crank

shaft

gear

Mark "0"

Mark "2"

Mark "1"

2

2

2

2

2

1

1

1

1

1

EA8M3004

Idle gear pin

Oil hole

EAMD083I

Idle gear pin

56

Torque 2.2 kg

•

m

Torque 3.1 kg

•

m

Measuring position

Backlash Limit

(between)

cam gear & idle gear 0.16 ~ 0.28 mm 0.35 mm

crank gear & idle gear 0.16 ~ 0.28 mm 0.35 mm

injection pump & idle gear 0.16 ~ 0.28 mm 0.35 mm

Loading...

Loading...