Section 6: Quick Start and Easy Setup

49

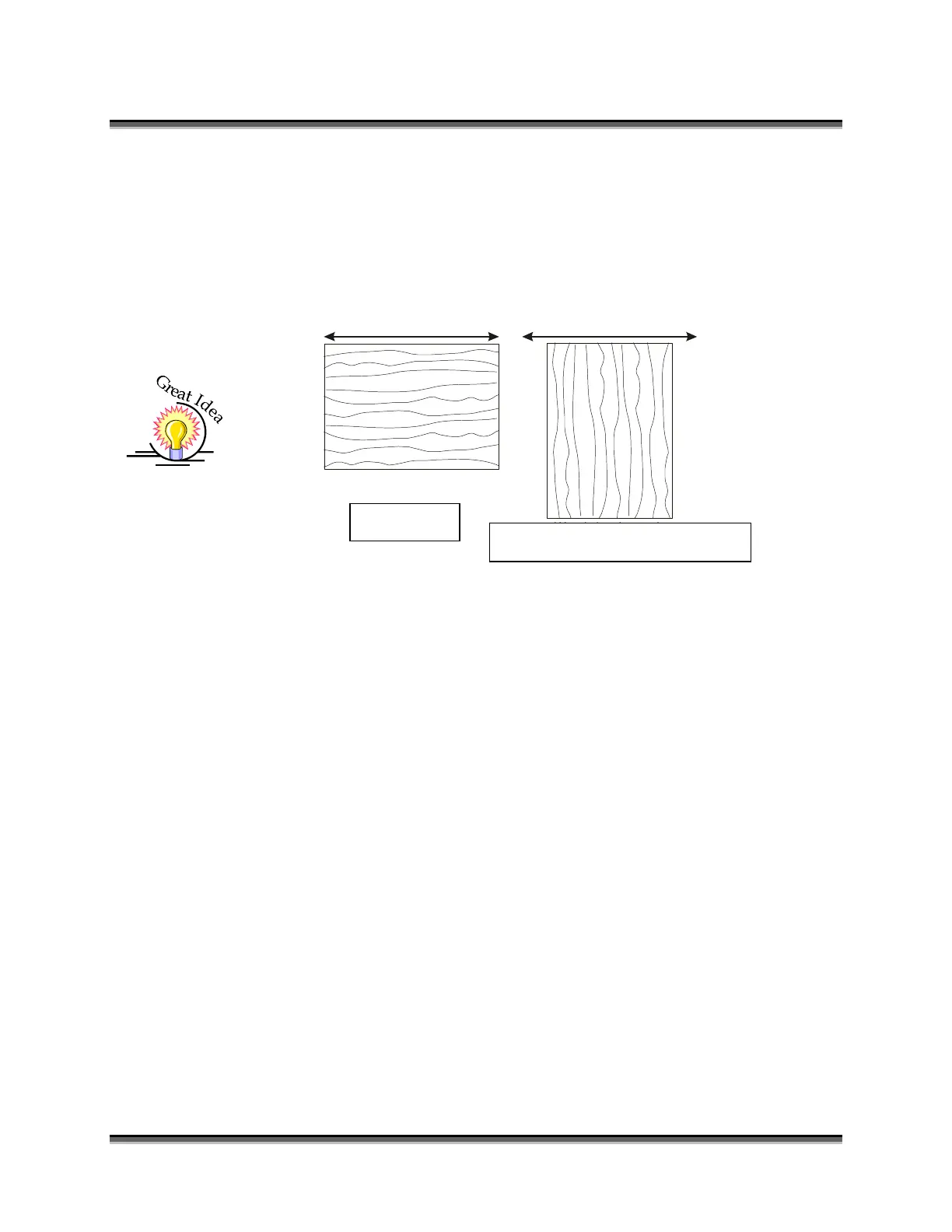

Material Orientation

Some materials such as wood or plastics that have a grain (brushed look) will look

nicer when engraved if the grain of the material runs parallel with the X-stroke of

the carriage. The orientation of material without a grain pattern is usually not

important.

Piece and Page Size

Many users like to create their artwork on a page size in Corel that matches the

size of the piece that is to be lasered. Compensating for beveled edges or placing

an image in an exact location is easy when there is a one-for-one relationship

between the material and the page size of the artwork. If this method works for

you, remember that you must also set the Piece Size dimensions in the Dashboard

to match the page size you have set in your graphics software.

On the other hand, many users do not want to change the Piece Size dimensions in

the Dashboard every time they print something new. They prefer to use a page

size that matches the table size (16 x 12 (406 x 305 mm) for the Zing 16) and

place their artwork into the upper left corner of the page. Both methods are

effective and it is a matter of personal preference which method is used.

Place the material to be engraved on the engraving table in the upper left hand

corner, pressing the material firmly against the metal rulers along the top and left

edges.

Most material does not need to be held or clamped in place. Simply setting it on

the table and letting gravity hold it in place is enough. If you are using a material

that is very thin and likely to move during operation you can hold it in place by

using the optional Zing Vector Grid (described later in this manual). The vector

Wood showing grain

Wood showing grain

Travel direction of carriage Travel direction of carriage

Preferred

Less desirable

Preferred

Less Desirable Orientation