25

3.3 ELECTRICAL INPUT CONNECTIONS

In order to provide a safe and convenient means to completely remove all electrical power from the machine, it is highly

recommended that a line disconnect switch be installed in the input circuit of the machine.

3.3.1 INPUT ELECTRICAL REQUIREMENTS

The primary input voltage requirements are shown on the power source nameplate. The power source is designed to be

operated from 208/230 vac single phase 50/60 Hz.

Before making electrical input connections to the welding machine, “Machinery

Lockout Procedures” should be employed. If the connections are to be made from

a line disconnect switch, the switch should be padlocked in the o position. If the

connection is to be made from a fusebox, remove the fuses and padlock the cover

closed. If no locking facilities are available, attach a red tag to warn others not to

energize the circuit.

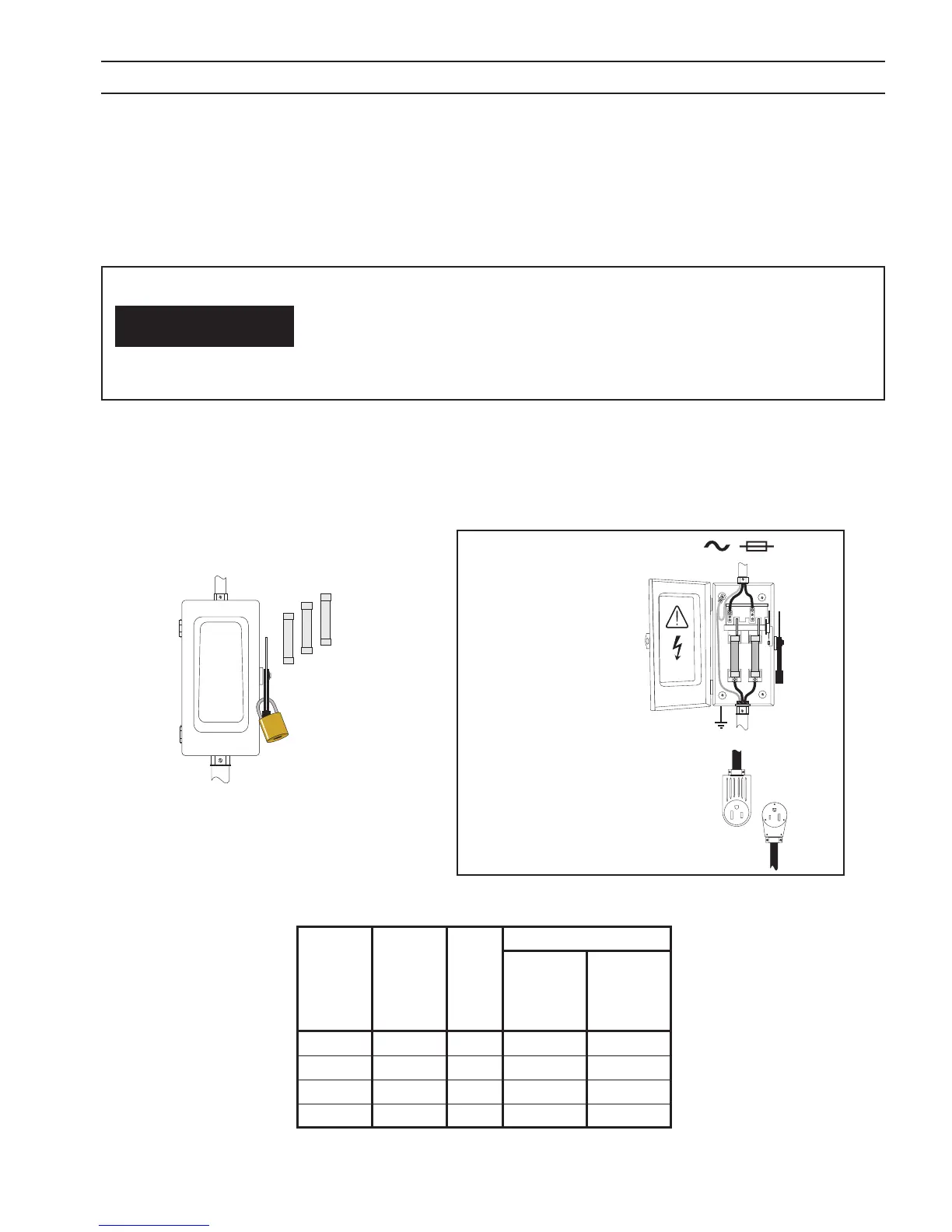

Typical Installation - User

Supplied Power Discon-

nect Box, Receptacle and

Plug

SECTION 3 INSTALLATION

WARNING

Primary

Input

Volts

Full

Load

Line

Amperes

Fuse

Size

Recommended

Primary

Input

Conductor

Size

Ground

Conductor

Size

208 57 90 8 8

230 52 90 8 8

460 26 30 12 12

575 20 30 12 12

Input Conductor and Fuse Size

Loading...

Loading...