7-1

7. MAINTENANCE AND

TROUBLESHOOTING

This chapter describes maintenance and troubleshooting procedures to keep the

equipment in good condition and restore normal operation in case of trouble.

7.1 Periodical Maintenance

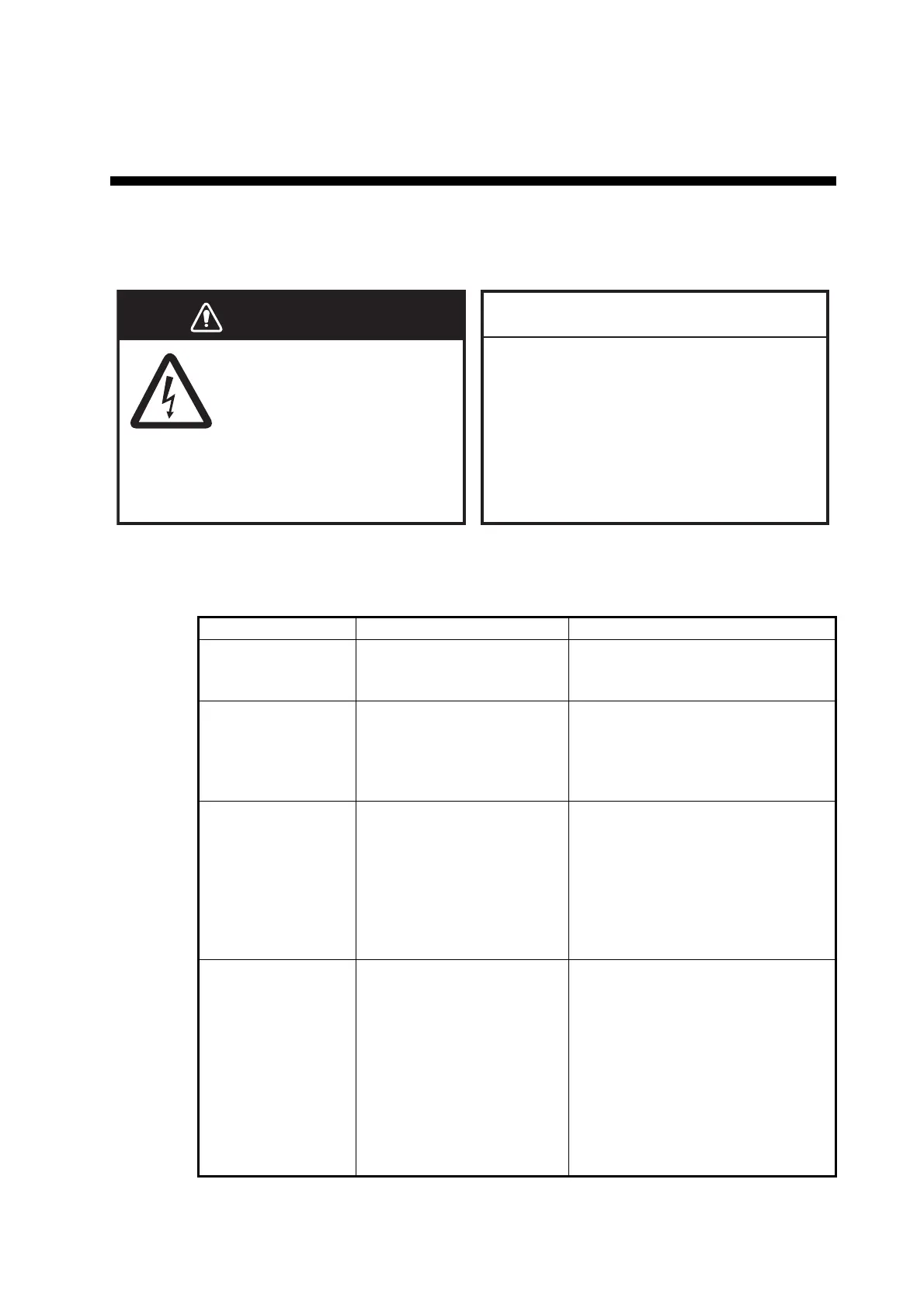

Check item Checkpoint Countermeasure

Cable (Connector) Check that all cables are

connected tightly and free

of corrosion.

If necessary, connect loosened ca-

bles, etc. If a cable is damaged, re-

place immediately.

Ground terminal Check that the ground wire

connected to the terminal is

tightly fastened and the ter-

minal is free of dust, dirt

and rust.

Remove dust and dirt from the ter-

minal. Tighten the wire if it has

loosened.

Communications

unit

Handset

Check that there is no dust

or dirt on the unit.

Clean the unit with a soft, dry cloth.

If the unit is very dirty, clean with

water-diluted mild detergent and

soft cloth. Wipe unit with clean cloth

after on a wet cloth then with a dry

cloth. Do not use alcohol or paint

thinners, as they can remove writ-

ing and marks on the panel.

Handset LCD

Screen

Check the screen for dust

and dirt, and that there are

no cracks on the screen.

Wipe the LCD carefully to prevent

scratching, using tissue paper and

an LCD cleaner. To remove dirt or

salt deposits, use an LCD cleaner,

wiping slowly with tissue paper so

as to dissolve the dirt or salt.

Change paper frequently so the

salt or dirt will not scratch the LCD.

Do not use solvents such as thin-

ner, acetone or benzene for clean-

ing.

WARNING

ELECTRICAL SHOCK HAZARD

Do not open the equipment.

This equipment uses high

voltage that can cause

electrical shock.

0nly qualified persons can

work inside the equipment.

NOTICE

Do not apply paint, anti-corrosive

sealant or contact spray to plastic

parts or equipment coating.

Those items contain products that can

damage plastic parts and equipment

coating.

Loading...

Loading...