80 ADL500 • Quick installation guide - Specifications and connection

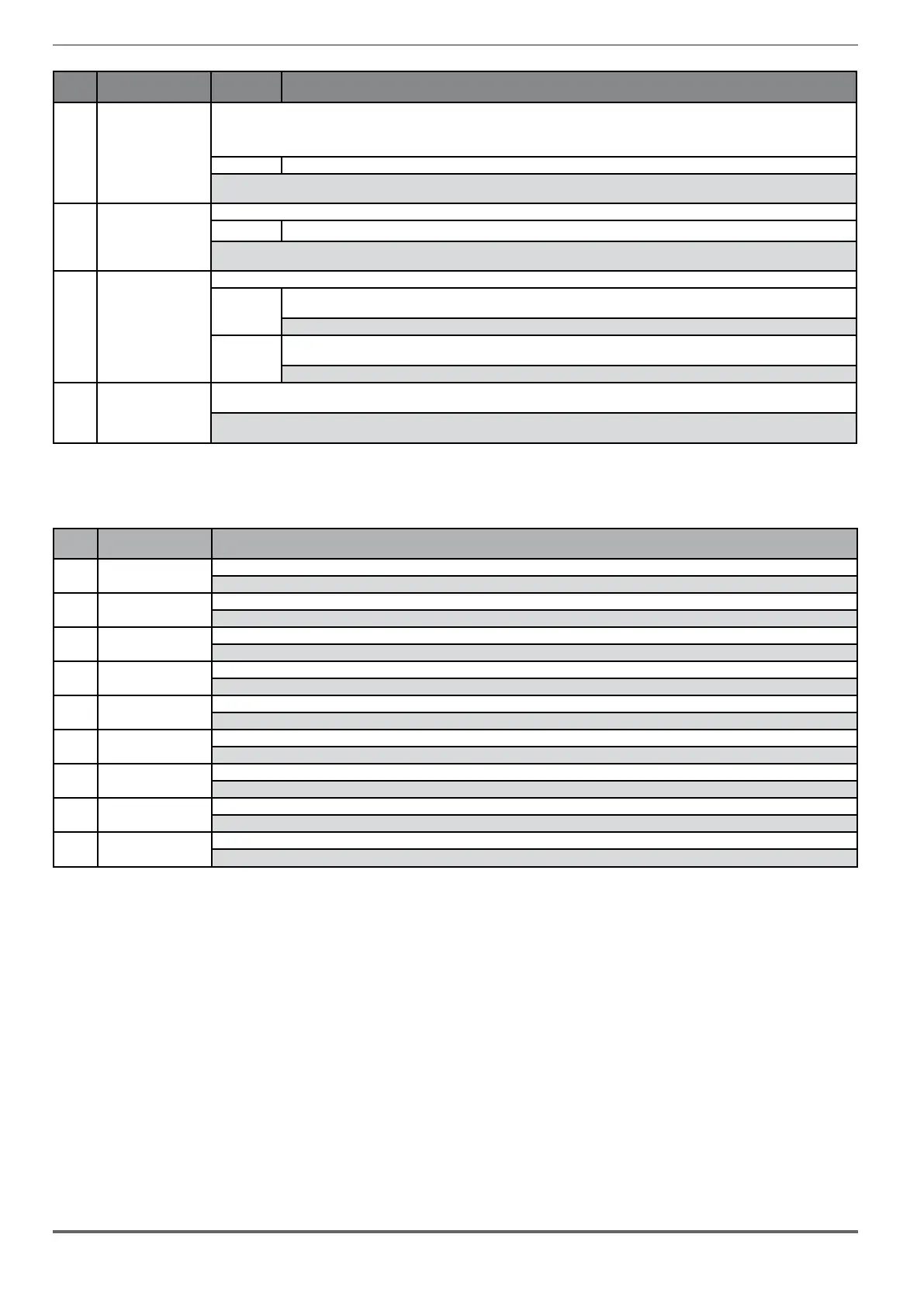

Index Error message shown

on the display

Sub-code Description

56 Load par def plc Condition: this can occur during loading of the parameter database saved in the Flash memory of the MDPLC application

it is normal if it appears the first time the drive is switched on, after downloading a new application. If this message appears when the drive is already in

use it means there has been a problem in the parameter database saved in the Flash memory.

If this message appears the drive automatically runs the Load default command.

0001H-1 The database saved is not valid

Solution: Set the parameters to the desired value and run Save parameter.

57 Key failed Condition: this can occur at drive power-on if the wrong enabling key is entered for a given firmware function

0001H-1 Incorrect PLC key. PLC application not available.

Solution: Contact Gefran to request the key to enable the desired firmware function.

58 Encoder error Condition: this condition may occur when the drive is powered during encoder setup each time parameter 552 Regulation mode is set.

100H-256 Cause: An error occurred during setup; the information received from the encoder is not reliable. If the encoder is used for feedback the

Speed fbk loss alarm is also generated.

Solution: Take the recommended action for the Speed fbk loss alarm.

200H-512 Cause: The firmware on the optional encoder card is incompatible with that on the regulation card. The information received from the

encoder is not reliable

Solution: Contact Gefran in order to update the firmware on the optional encoder card.

59 Opt cfg change

Condition: an optional card has been removed with respect to the configuration present when the last Save parameters command was executed or there

is a fault on the optional card or on the regulation card.

Solution: If the user has removed the card on purpose, execute Save parameters. If the user has not removed the card, identify and replace the faulty

card.

10.1.1 EFC application alarms

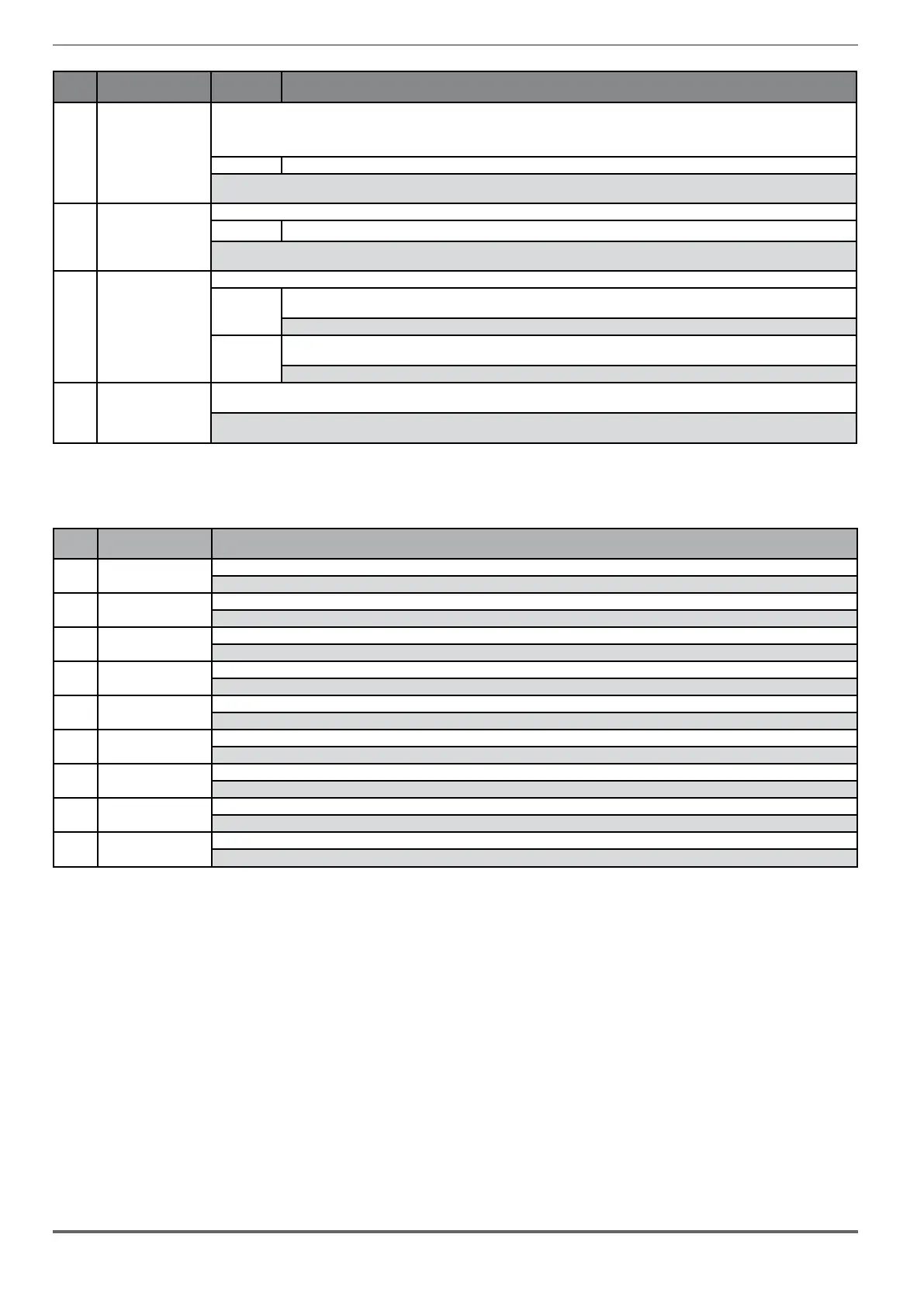

Index

Error message shown

on the display

Description

33

Cont feedback Condition: The contactor feedback signal does not match its command.

Solution: Check contactor feedback wiring, check logic status of feedback input to drive, increase hold off time (PAR 11202).

34

Brake Feedback Condition: The brake feedback signal does not match its command.

Solution: Check brake feedback wiring, check logic status of feedback input to drive, increase hold off time (PAR 11206).

35

Door Feedback Condition: The door feedback signal does not match its command.

Solution: Check door feedback wiring, check logic status of feedback input to drive, increase hold off time (PAR 11212).

36

Brake Failure Condition: Exceeding the Threshold A3 (PAR 11270).

Solution: Reset alarm using the reset parameter (PAR 11268), check that brake is intact, increase threshold (PAR 11270).

37

Safe Brake Test Condition: Brake force test failed.

Solution: Check that brake is intact, increase the maximum deviation threshold (PAR 11840).

38

Speed limit Condition: Speed limitation warning to ensure stopping, enabling the DISTANCE function.

Solution: Check multi-speed selected for current distance.

39

Up/low limit Condition: Speed threshold exceeded in limit switches zone (sensors installed at the top and bottom of the lift/elevator shaft).

Solution: Check speed set in limit switches zone, change speed limit (PAR 11216).

40

Lift ext fault Condition: External alarm signal triggered (PAR 11258).

Solution: Check causes enabling external alarm signal, increase hold off time (PAR 11266).

41

Battery Low Condition: Battery monitoring alarm triggered.

Solution: Check whether battery is properly connected to drive.

Loading...

Loading...