Diagnostic Repair Manual 27

Section 3 Troubleshooting Flowcharts

Introduction

The most important step in troubleshooting is identifying

the actual problem. The next step is to determine the

applicable flow chart to use to help diagnose the

problem.

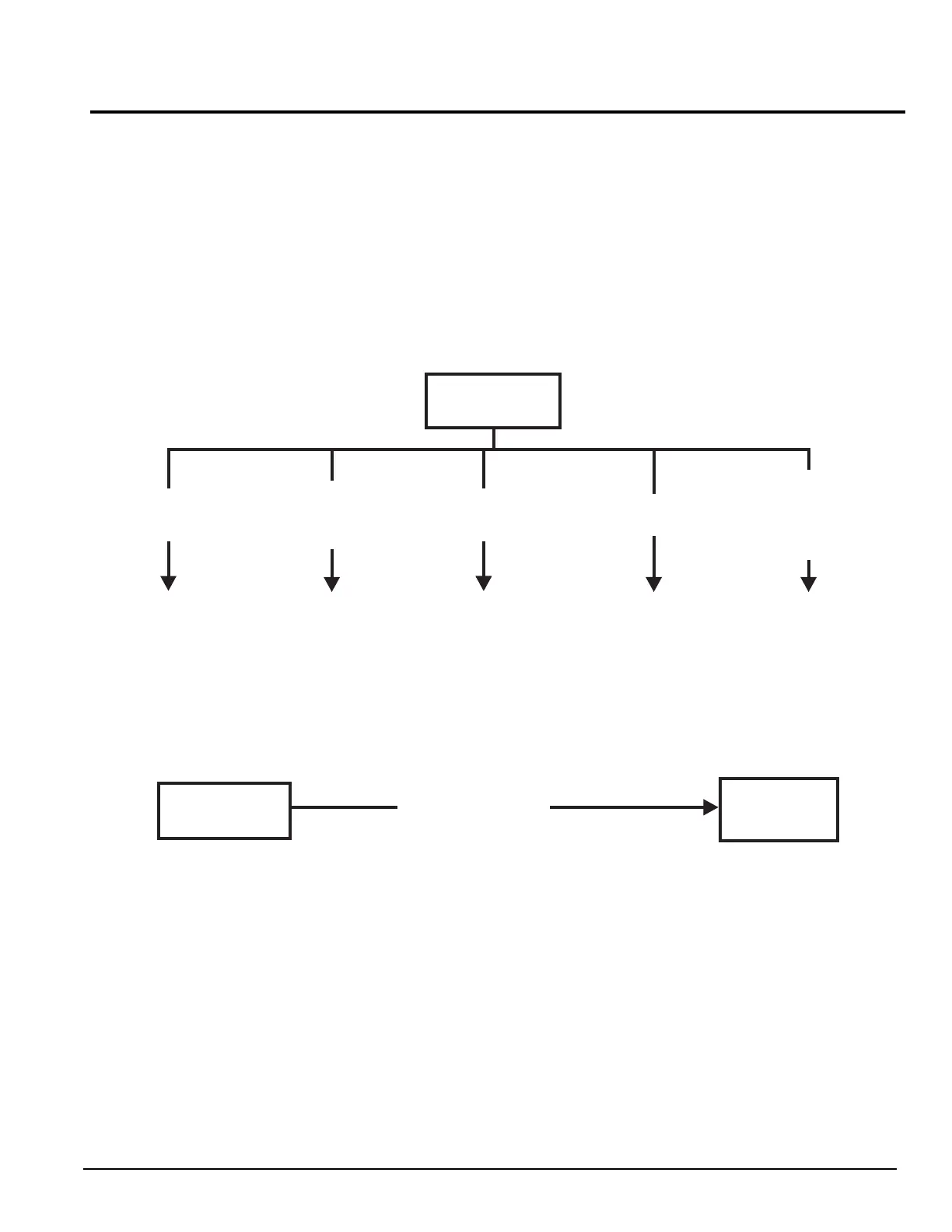

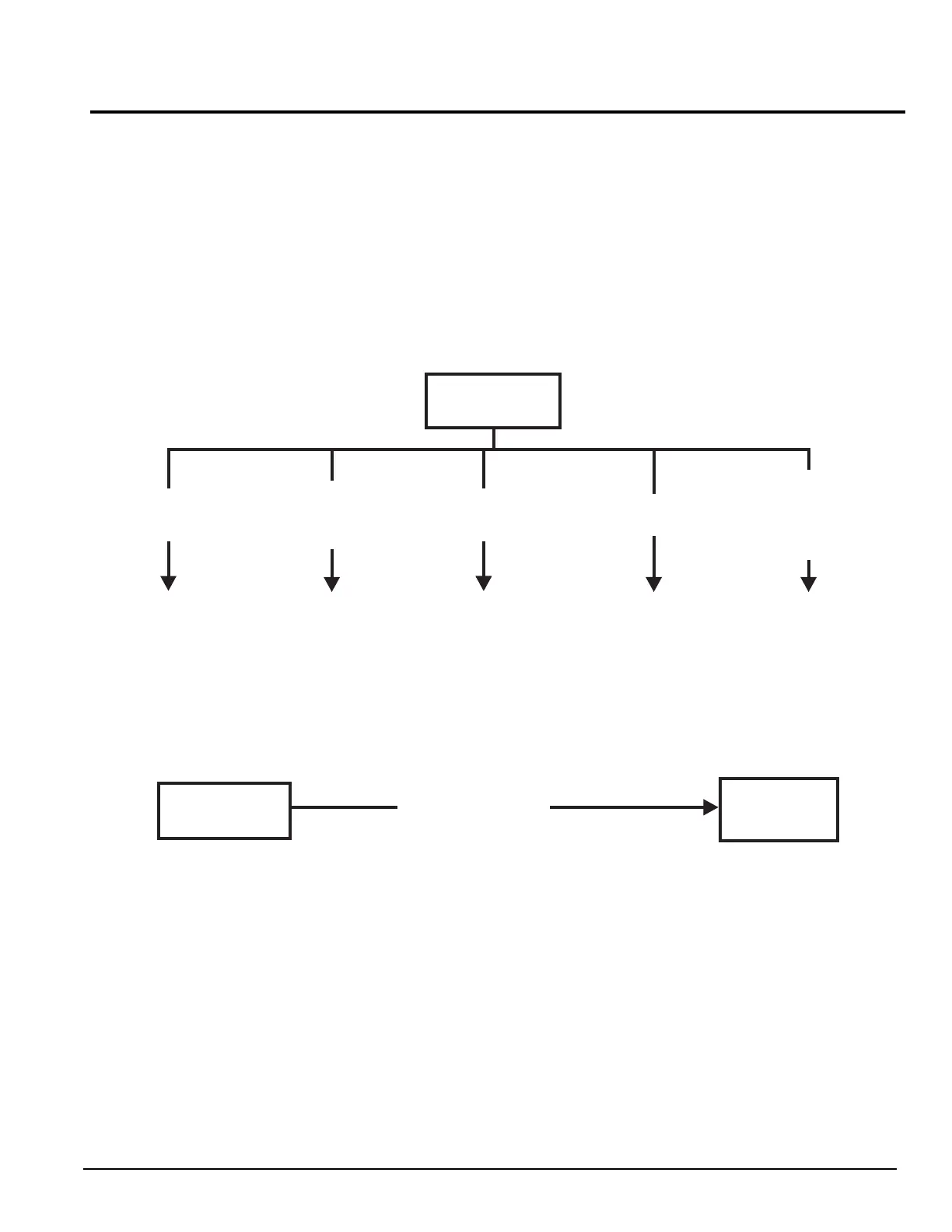

For each flow chart, start at the top and use the indicated

test to verify whether or not a component or control item

is working properly. At the end of each test follow the

GOOD or BAD arrows and perform the next test.

Use the flow charts in conjunction with the detailed

instructions in section 4. Test numbers used in the flow

charts correspond to the numbered tests in section 4. For

best results, perform all tests in the exact sequence

shown in the flow charts.

If Problem Involves AC Output

Problem 1 – Voltage and Frequency Are Both High or Low

GO TO PROBLEM 1

(BELOW)

GO TO PROBLEM 2 GO TO PROBLEM 2 GO TO PROBLEM 3GO TO VOLTAGE

REGULATOR

ADJUSTMENT,

PAGE 11

TEST 1 - CHECK NO

LOAD VOLTAGE &

FREQUENCY

VOLTAGE &

FREQUENCY BOTH

HIGH OR LOW

FREQUENCY GOOD -

ZERO OR RESIDUAL

VOLTAGE

ZERO VOLTAGE AND

ZERO FREQUENCY

FREQUENCY GOOD -

VOLTAGE HIGH

OR

VOLTAGE LOW

NO-LOAD VOLTAGE &

FREQUENCY GOOD -

VOLTAGE/FREQUENCY

FALLS OFF UNDER LOAD

TEST 5 - CHECK

STEPPER MOTOR

CONTROL

GO TO VOLTAGE

REGULATOR

ADJUSTMENT,

PAGE 11

FREQUENCY IS GOOD,

BUT NO-LOAD

VOLTAGE IS HIGH

OR VOLTAGE

IS LOW

Loading...

Loading...