Section 4 AC Diagnostic Tests

Diagnostic Repair Manual 61

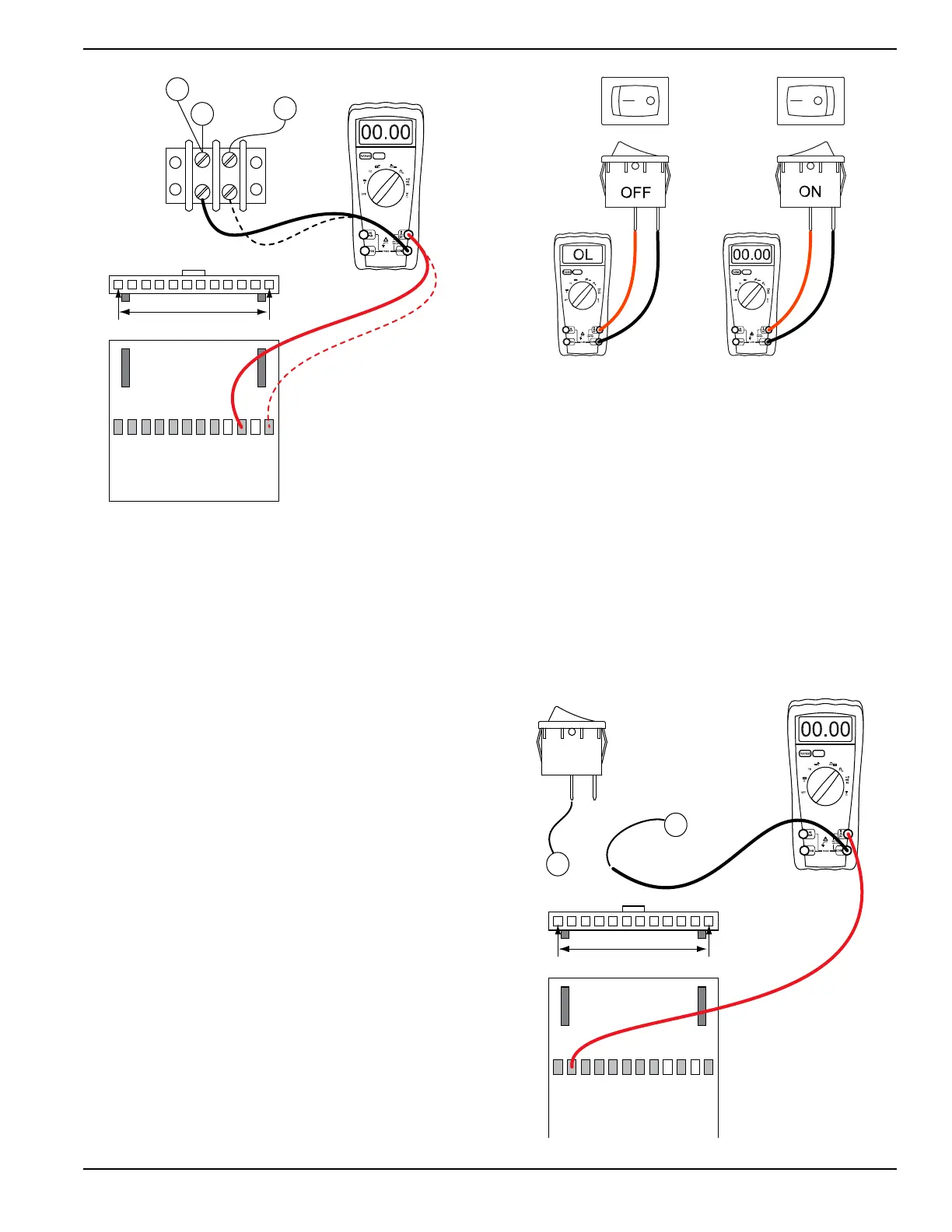

Figure 4-57. Check Wires 11S & 44S or 11S & 22S

6. Connect the other meter test lead to wire 11S at

terminal block 2 (TB2).

a. Continuity should be measured.

NOTE: Where terminal block is not present, place meter

test lead on the wire at the termination point. If

necessary, use a small paper clip to probe beside the

wire so as not to damage the terminal in the connector.

Results

1. If Continuity was not measured, repair or replace

the wire harness.

2. If Continuity was measured, refer back to the flow

chart.

Test 52 – Check Idle Control Switch

(SW2)

Procedure

1. Set DMM to measure resistance.

2. Disconnect wire 0 and wire 83 from the idle control

switch (SW2).

3. See Figure 4-58. Connect meter test leads across

both terminals of SW2.

a. In the OFF position Infinity should be

measured.

b. In the ON position Continuity should be

measured.

Results

1. If the switch fails step 3 replace it.

2. If the switch is good refer back to the flow chart.

Figure 4-58. Check Idle Control Switch (SW2)

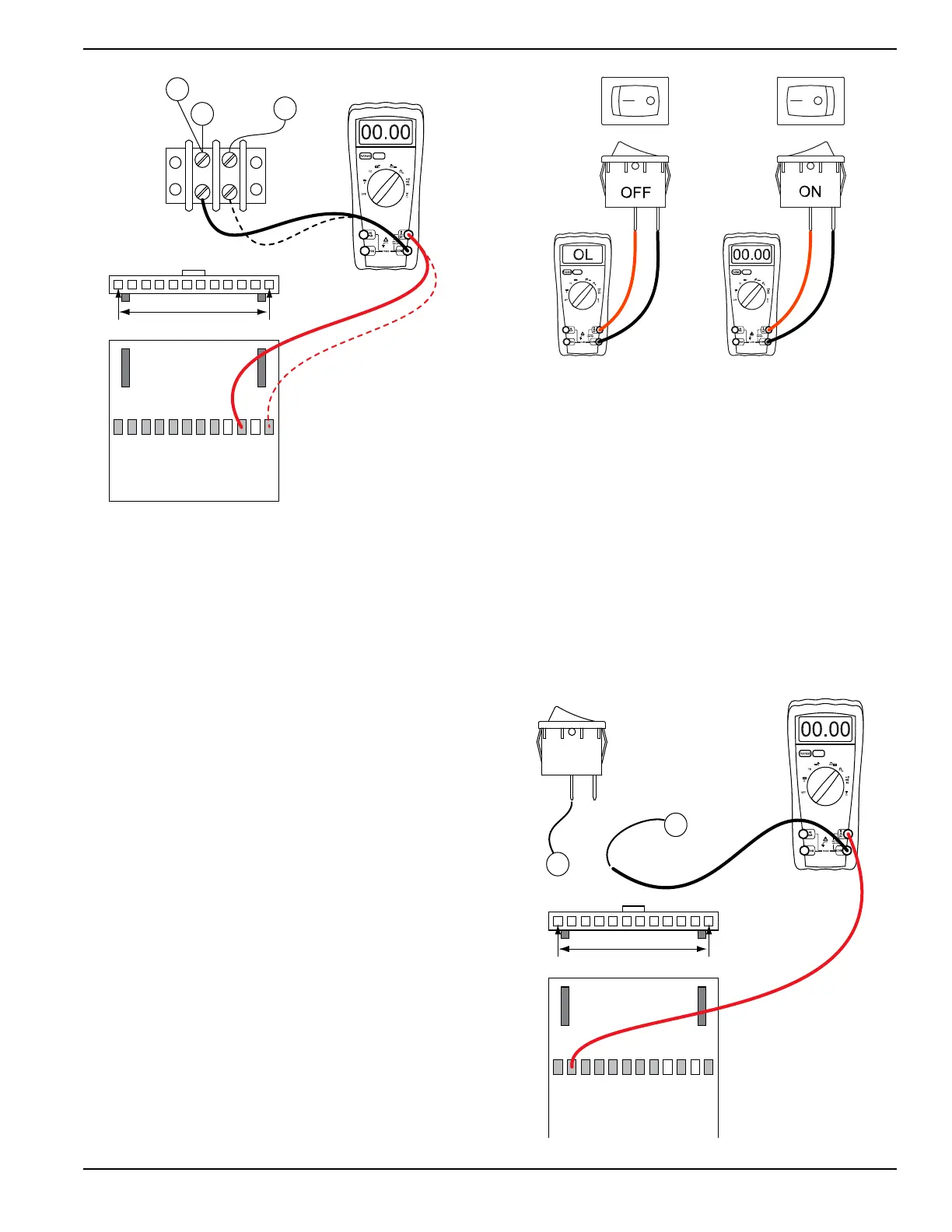

Test 53 – Check Idle Control Wiring

Procedure

1. Set DMM to measure resistance.

2. Disconnect wire 0 from the Idle Control Switch

(SW2).

3. Connect one meter test lead to wire 0.

4. Connect the other meter test lead to frame ground.

Continuity should be measured.

a. If continuity is not measured repair or replace

wire 0 between SW2 and the ground terminal.

5. Disconnect wire 83 from SW2.

6. Disconnect the J2 connector from the printed

circuit board.

Figure 4-59. Check Idle Control Wiring

J2 HARNESS CONNECTOR

J2-1 J2-12

TB2

22S NEWER

STEP 2

STEP 3

STEP 2

STEP 3

11S

44S OLDER

J2 HARNESS CONNECTOR

SW2

J2-1 J2-12

0

83

Loading...

Loading...