Section 4 AC Diagnostic Tests

54 Diagnostic Repair Manual

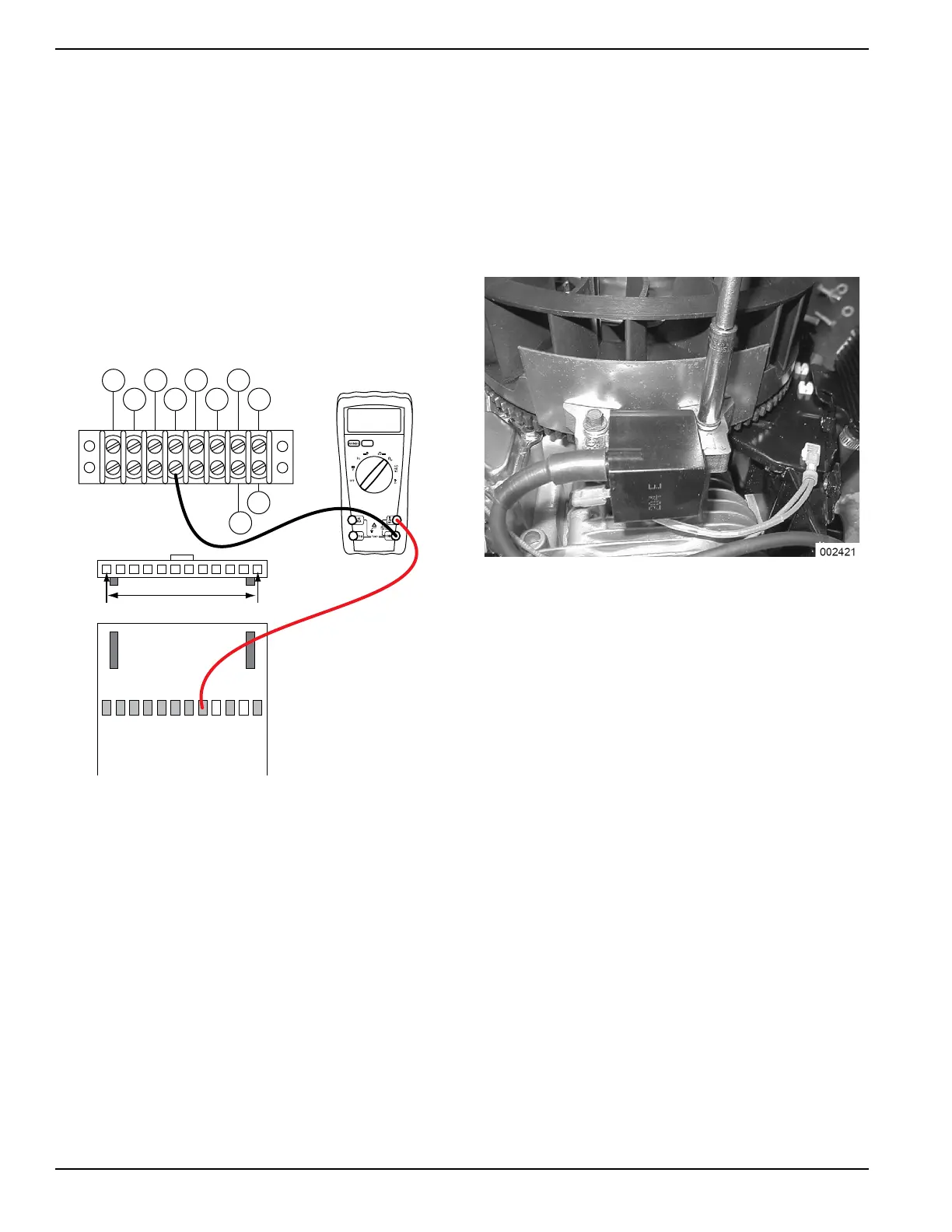

7. If voltage was not measured in step 3 connect one

meter test lead to wire 229 removed from the SSR.

8. Connect the other meter test lead to wire 229 at the

terminal block 1 (TB1). Continuity should be

measured.

a. If continuity is not measured repair or replace

wire 229 between SSR and TB1.

NOTE: Where terminal block is not present, place meter

test lead on the wire at the termination point. If

necessary, use a small paper clip to probe beside the

wire so as not to damage the terminal in the connector.

9. Remove the J2 connector the printed circuit board.

10. Connect one meter test lead to pin location J2-8

(wire 229)

Figure 4-47. Testing Wire 229 Between J2 Connector

and Terminal Block 1 (TB1)

11. See Figure 4-47. Connect the other meter test

lead to wire 229 at TB1. Continuity should be

measured.

a. If continuity is not measured repair or replace

wire 229 between the J2 connector and TB1.

Results

1. If step 5 passed refer to Flow Chart.

2. If step 5 failed and step 11 passed replace the

printed circuit board.

Test 35 – Check and Adjust Ignition

Magnetos

Procedure

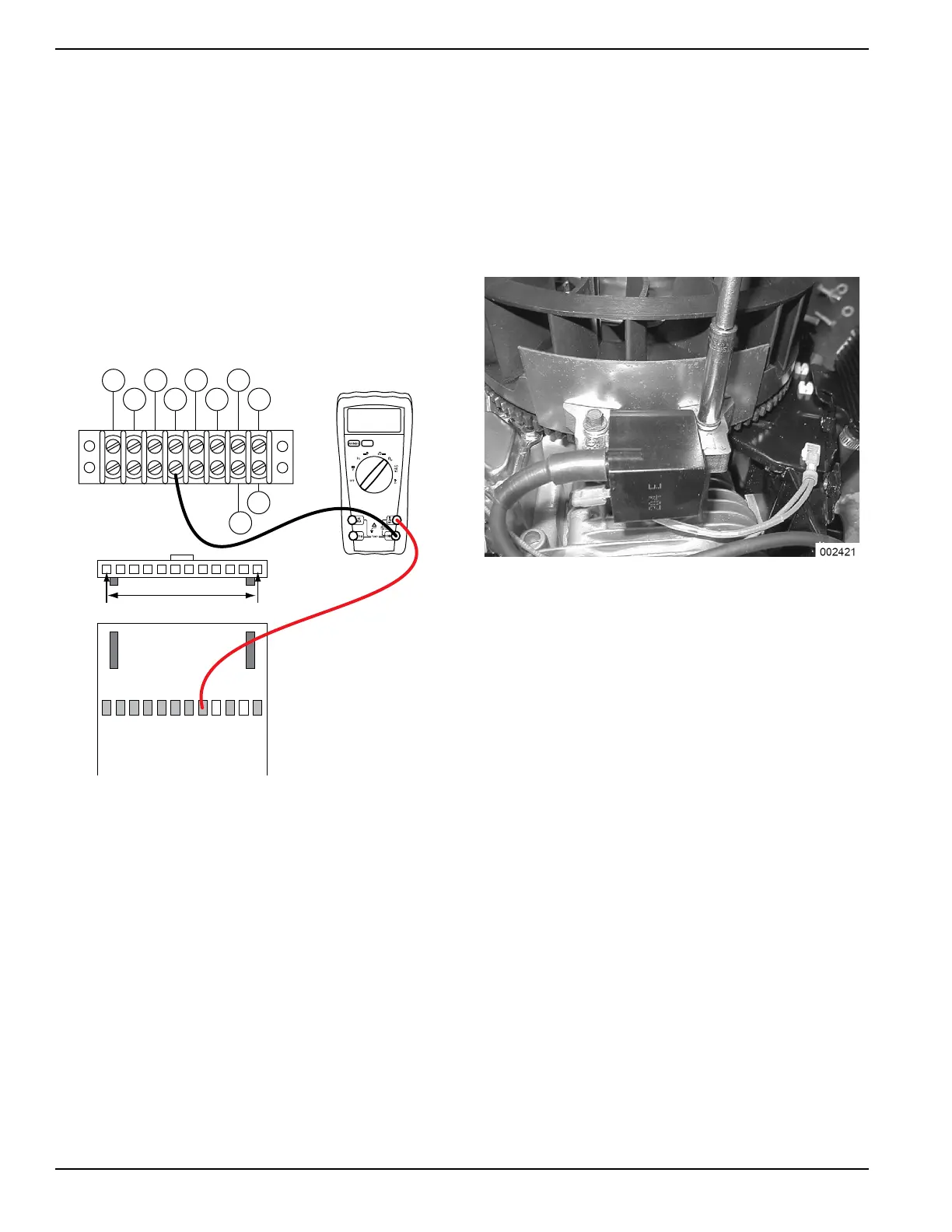

1. See Figure 4-48. Rotate the flywheel until the

magnet is under the module (armature)

laminations.

2. Place a 0.008-0.012 inch (0.20-0.30mm) thickness

gauge between the flywheel magnet and the

module laminations.

Figure 4-48. Setting Ignition Magneto Air Gap

3. Loosen the mounting screws and let the magnet

pull the magneto down against the thickness

gauge.

4. Tighten both mounting screws.

5. To remove the thickness gauge, rotate the

flywheel.

6. Repeat the above procedure for the second

magneto.

7. Repeat Test 29 – Check Ignition Spark and

check for spark across the spark tester gap.

8. If air gap was not out of adjustment, remove engine

ground harness from magnetos. Repeat Test 29 –

Check Ignition Spark. If sparking now occurs

replace engine ground harness.

9. Check the flywheel magnet by holding a

screwdriver at the extreme end of its handle and

with its point down. When the tip of the screwdriver

is moved to within 3/4 inch (19 mm) of the magnet,

the blade should be pulled in against the magnet.

10. Check the flywheel key. The flywheel’s taper is

locked on the crankshaft taper by the torque of the

flywheel nut. A keyway is provided for alignment

only and theoretically carries no load.

NOTE: If the flywheel key becomes sheared or even

partially sheared, ignition timing can change. Incorrect

timing can result in hard starting or failure to start.

TB1

J2 HARNESS CONNECTOR

00.00

86 15B

167

BLK

0 229

83

BLK

TR2

TR1

J2-1 J2-12

Loading...

Loading...