Section 4 AC Diagnostic Tests

Diagnostic Repair Manual 47

Results

1. If continuity was measured the breaker is good

refer back to the flow chart.

2. If Infinity or a open condition was measured

replace the circuit breaker.

Test 21 – Check 10 Amp Fuse

Procedure

Push in on fuse holder cap and turn counterclockwise to

remove the cap with fuse. Inspect the fuse.

Figure 4-28. 10 Amp Fuse (Located in Rear of Control

Panel)

Results

If the fuse element has melted open, replace with an

identical size fuse. If fuse is good, refer back to flow chart.

Test 22 – Check Battery and Cables

General Theory

Battery power is used to (a) crank the engine and (b) to

power the circuit board. Low or no battery voltage can

result in failure of the engine to crank.

The battery charging circuit is not designed to recharge a

dead battery. As well, if there is a loose connection or

corrosion associated with a wire (positive or negative),

battery voltage may be present, but due to high

resistance, will not allow current to flow.

Electrical voltage drop varies according to current flow.

Voltage drop cannot be measured unless the circuit is

operated so current can flow through it. A crank attempt

will need to be performed to properly measure voltage

drop. This test will determine whether the battery, battery

cables, or both are at fault.

Procedure A – Perform Starter Circuit Voltage

Drop Test

1. Set a DMM to measure DC voltage.

2. Connect the red meter test lead to the positive

battery post and connect the black meter test lead

to the negative battery post.

a. If battery voltage is 12.1 VDC or below,

recharge the battery and retest.

b. If battery voltage is 12.2 VDC or above,

proceed to next step. (For this test, battery

voltage should be at least 12.2 VDC)

3. To inhibit any possible startup, turn off the fuel

source and ground wire 18 at the stud located

above the oil cooler. See Figure 4-39.

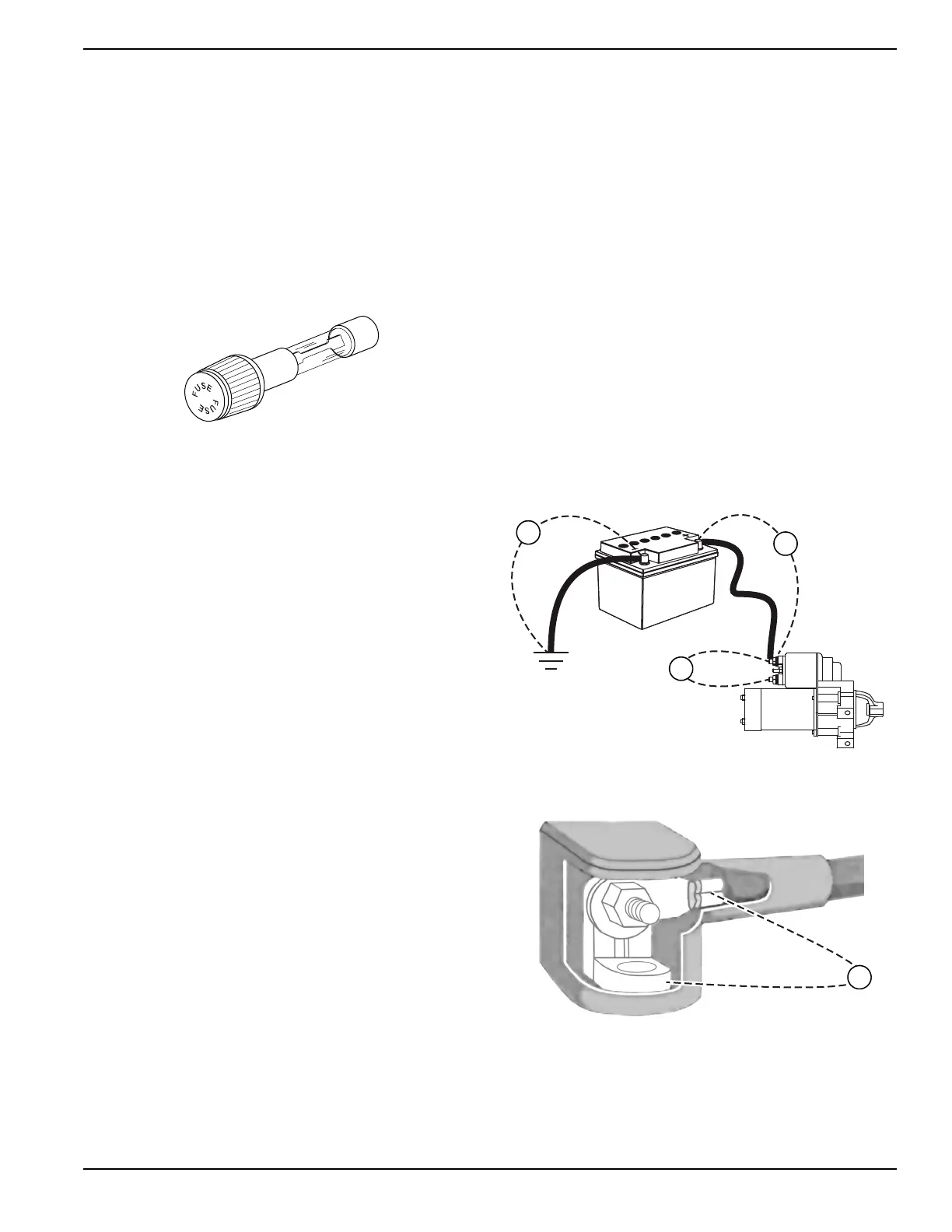

4. Refer to battery post and starter connections in

Figure 4-29 and Figure 4-30 then perform a

voltage drop test as indicated.

5. Set the start-run-stop switch to START. Allow the

engine to crank long enough to obtain a steady

measurement.

6. Record voltage readings from test points V1, V2,

V3 and V4. Although resistance-free connections,

wires and cables would be ideal, most of them will

contain at least some voltage drop. The maximum

voltage readings should be as follows:

a. 0.00-0.10 VDC across a connection or battery

post (V4).

b. 0.10-0.20 VDC on a ground connection.

c. 0.20-0.30 VDC across a wire or cable (V1, V2).

d. 0.20-0.30 VDC across a switch or starter

contactor (V3).

e. 0.40-0.50 VDC across the entire circuit

Figure 4-29.

Figure 4-30.

7. If voltage drop is greater than the above, based on

the circuit or component, clean or replace the failed

connection or component. If voltage drop test

results are within the above, based on the circuit or

component, refer back to the flowchart.

Loading...

Loading...