IV.

FRAME

8. Remove the socket boll and separate

the

front fork pipe

and

oil lock piece from the

bottom

case. Use "Allen

Head wrench"(Tool

No.

07917-3230000)

to

remove the

socket

boll

9. Remove the front fork bolt

on

top

of

the fork pipe:

remove the front shock absorber spring and bottom

pipe.

JO.

Remove the

bottom

case cover, dust seal and snap ring,

and take

ou

t the oil sea

l.

ln~pection

I.

Check the free length

of

the front shock absorber

spring.

Standard

V11lue:

453.7mm (17.R622-in.)

Service limit:

445mm

(17.5197-in

.)

2.

Check the

bollom

pipe for wear

on

the piston ring.

3.

Check the front fork piston and

bottom

case for wear,

cra

ck

or any other defecL

Standard

bottom case

T.D.:

31.000

-3

1.039mm

(I

.220S- 1.2220.in.)

Sen

·i

ce

limit: 31.14mm (1.226-in.)

Standard

fork pi<ton O.D.:

30.92S-30.950mm

(l

.217S-l.218S-i.Jt.)

Service

limit: 30.90mm (1.216S-in.)

4 Check the oil seal

for

wear

or

damage.

Assembly

I.

Clean

all

parts

in

solvent before assembly.

2 Apply a coating

<lf

ATF (automatic transmission fluid)

to the entire surface

of

a new oil seal. Install the oil

seal

to

the

bottom

case. Drive fit

th

e seal using

"fork

Seal Driver" (Tool

No.

07947-

3550000).

NOTE:

Be

sure

to

iostall

the

dust

cover securely.

3.

Install the front shock absorber spring inro the front

fork pipe so

lhat

the e

nd

with the lar

ge

pitch

is

at

the

bouom.

4.

Install the fron( fork pipe

co

the bottom case.

NOTE:

Apply liquid sealant

to

the threads

of

the

8mm

socket

bolt.

5.

Fill each front fork

bottom

case

wich

128- 132 cc

(4.3 4.5

02S)

of

ATF.

55

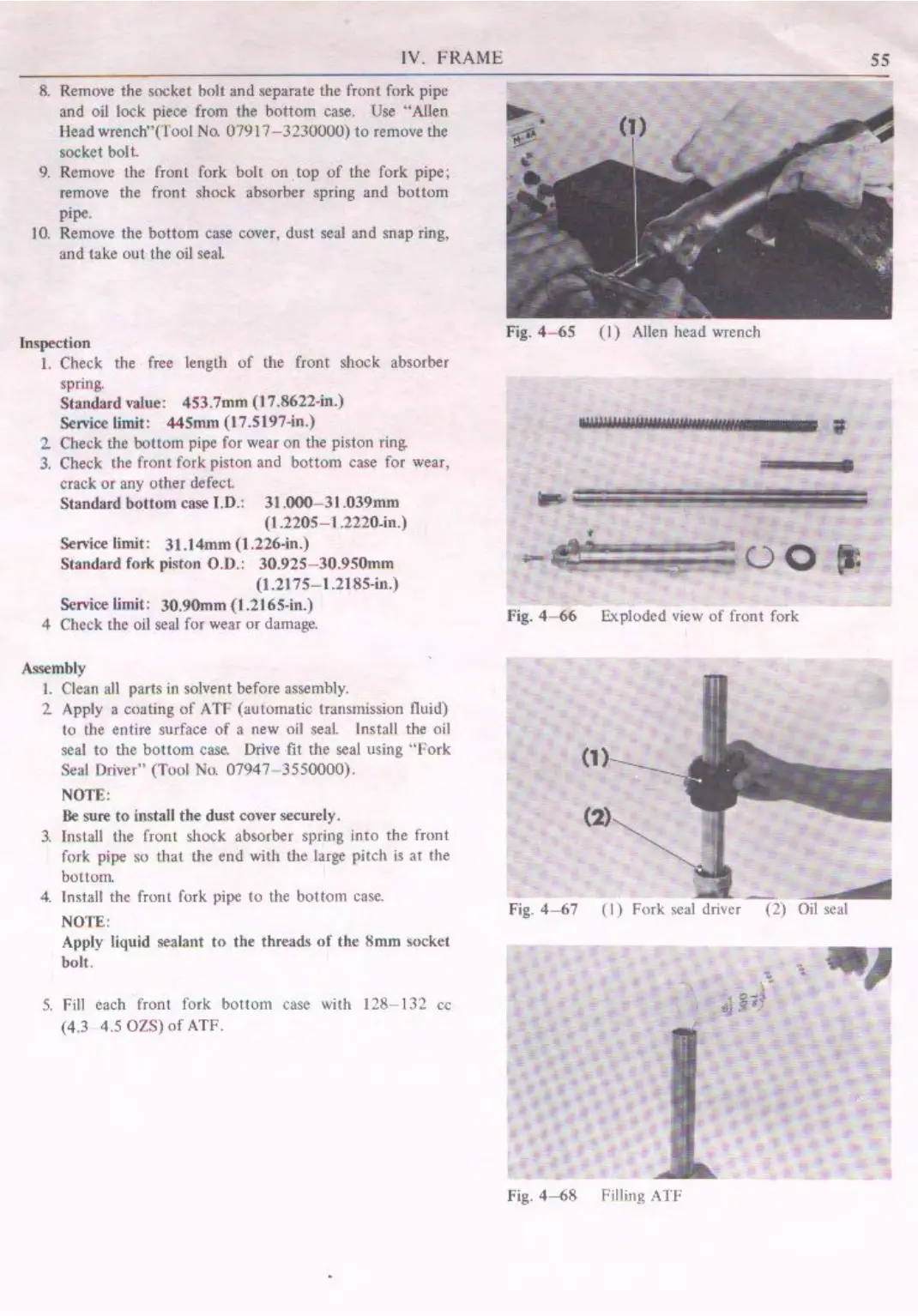

Fig.

4-65

(I)

Allen head wrench

,,,,,.,,,.,,,,,,,,,,,ifiit

I ?ii I

-

Fig. 4-

66

Exploded view

of

front fork

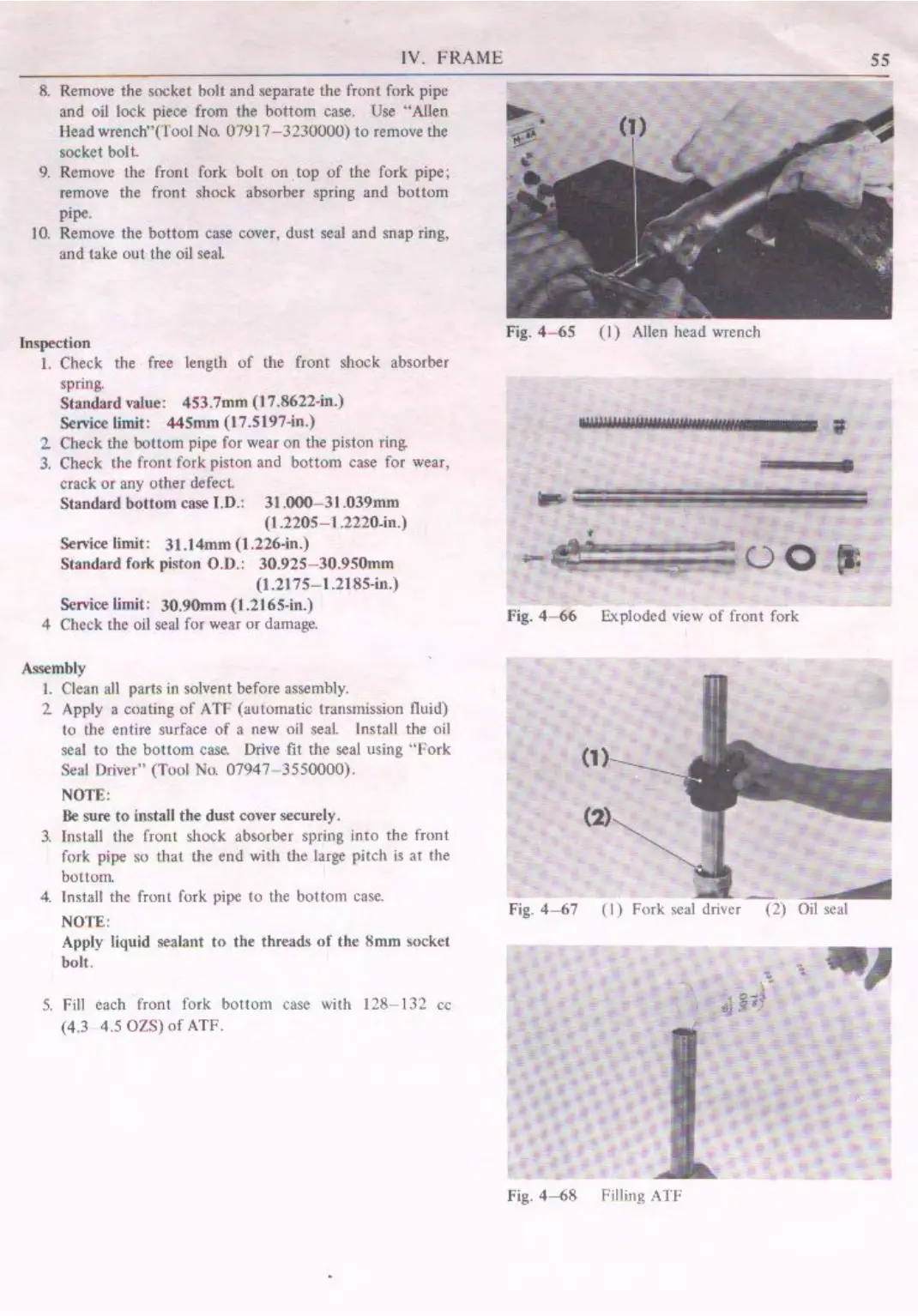

(1)

(2)

Fig.

4-67

(I)

Fork seal driver

Oil

seal

Fig.

4-68

filling AT!'

Loading...

Loading...