10-14

CAMSHAFT/CRANKSHAFT/ PISTON/CYLINDER HRN216

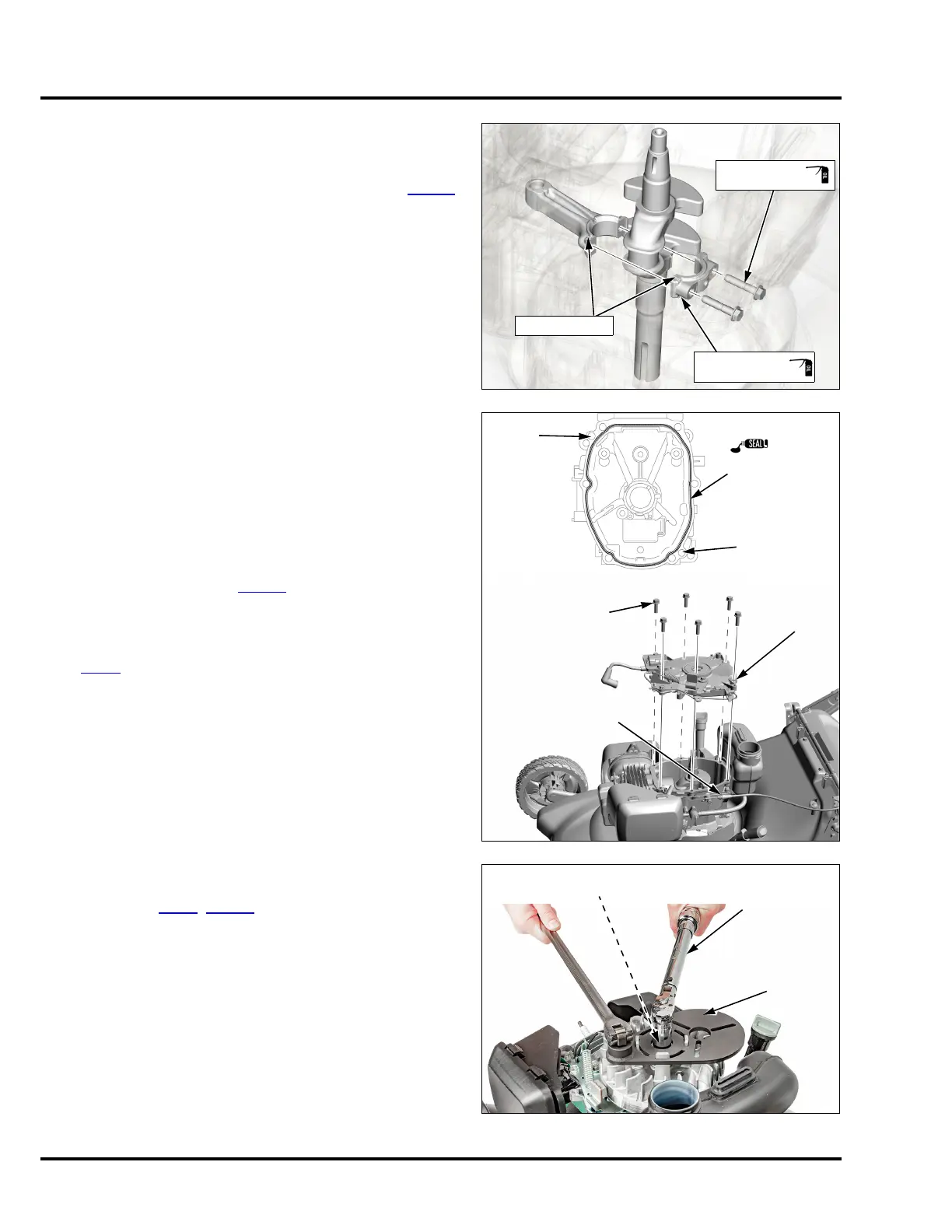

6. Apply clean engine oil to the connecting rod, end cap,

crankshaft, and connecting rod bolts.

Reinstall the connecting rod to the crankshaft and tighten

the connecting rod bolts to the specified torque (P. 10-8

).

Be sure the projections on the connecting rod and end

cap are aligned on the same side.

TORQUE: 12 N•m (9 ft-lb)

7. Thoroughly clean the crankcase and crankcase cover

mating surfaces, and then apply a bead [Ø 1.0 - 2.0 mm

(Ø 0.04 - 0.08) in diameter] of liquid gasket (Hondabond

HT, Loctite 5900, or equivalent).

Be sure both crankcase bosses are installed and seated

in the crankcase.

Install the crankcase cover with ignition coil and flywheel

brake assembly, and then tighten the six 8 x 25 mm bolts

to the specified torque (P. 1 0 -2

).

TORQUE: 24 N•m (18 ft-lb)

8. Reconnect the breather tube to the crankcase cover

(P. 8 -2

).

9. PKA/VKA/VLA types only:

Reconnect the flywheel brake cable and Z-fitting to the

brake assembly and then pull the flywheel brake lever and

secure the lever to the handlebar with a strap or

equivalent material.

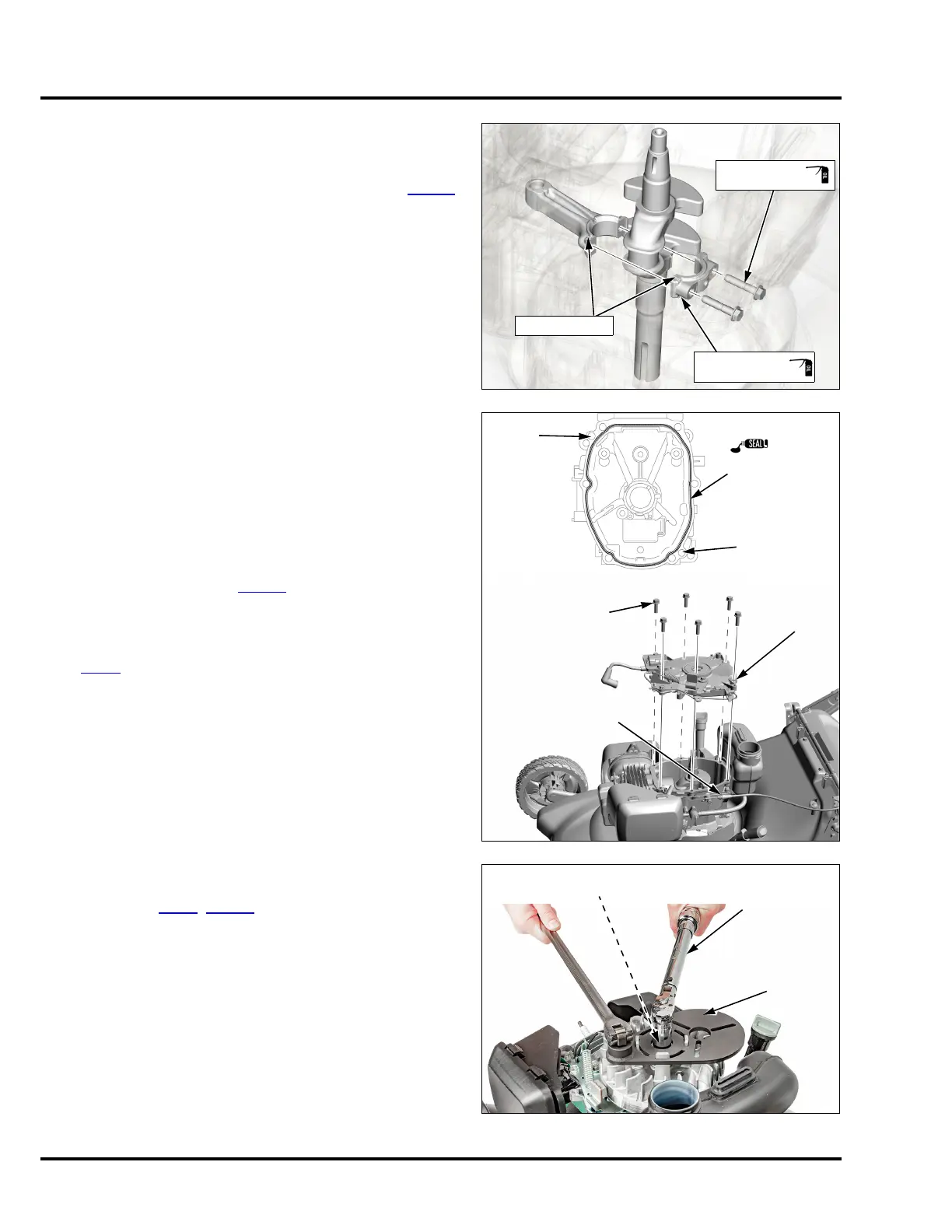

10. Install the flywheel. Make sure the flywheel taper is free of

dirt, oil, grease and other foreign material before

installation (P. 9 - 8

, P. 9-10).

a. Be sure the woodruff key is set in the keyway properly.

b. Apply engine oil to the flywheel nut threads.

c. Holding the flywheel with the flywheel holder special

tool or a commercially available strap wrench, tighten

the 14 mm special nut to the specified torque.

TOOLS:

FLYWHEEL HOLDER 07APB-Z28A101

TORQUE:

PKA/VKA/VLA types: 55 N•m (41 ft-lb)

VYA type: 75 N•m (55 ft-lb)

CONNECTING

ROD BOLT (2)

CONNECTING

ROD END CAP

PROJECTIONS

Apply a bead of

liquid gasket as

shown.

CRANKCASE

BOSS

CRANKCASE

BOSS

8x25mm

FLANGE BOLT (6)

Reconnect the

flywheel brake cable

and Z-fitting.

CRANKCASE

COVER ASSY.

SPECIAL NUT, 14 mm

FLYWHEEL

HOLDER

P/N 07APB-Z28A101

TORQUE

WRENCH

(commercially

available)

Loading...

Loading...