3-60

24. SERVICE PROCEDURE

24.6.5 CHECK, AIR CONDITIONER COMPRESSOR BELT

TENSION, ADJUST

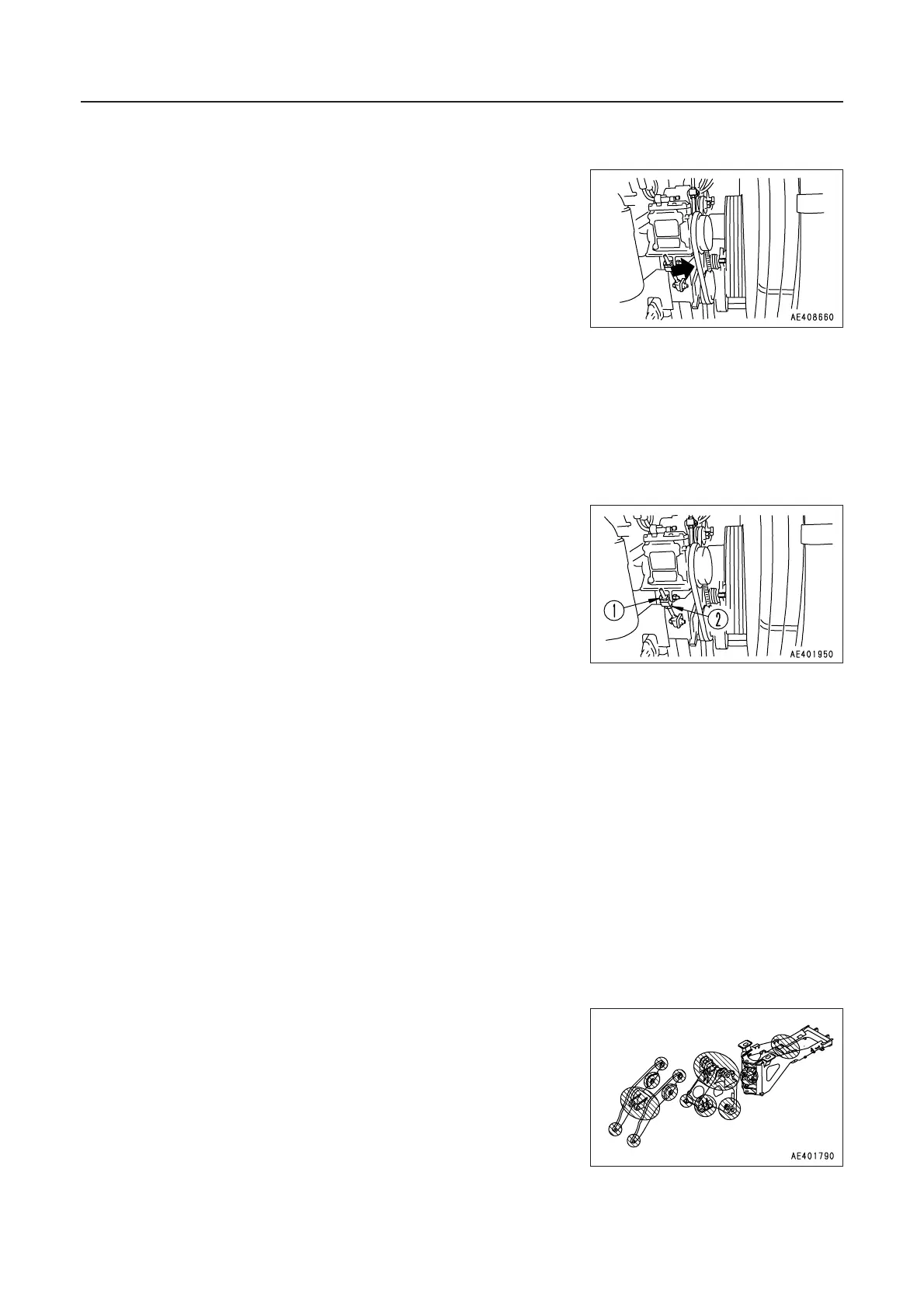

Checking

The deflection should be approx. 12.5 – 16.5 mm (0.5 – 0.7 in)

when pressed with a finger force of approx. 98.1 N (10 kgf) at a point

midway between the air conditioner compressor pulley and drive

pulley.

When using a belt tension gauge, the tension should be in a

range of 353 – 530 N (36 – 54 kgf).

Checking when replacing V-belt

The deflection should be approx. 9.0 – 12.5 mm (0.355 – 0.5 in)

when pressed with a finger force of approx. 98.1 N (10 kgf) at a point

midway between the air conditioner compressor pulley and drive

pulley.

When using a belt tension gauge, the tension should be in a

range of 530 – 745 N (54 – 76 kgf).

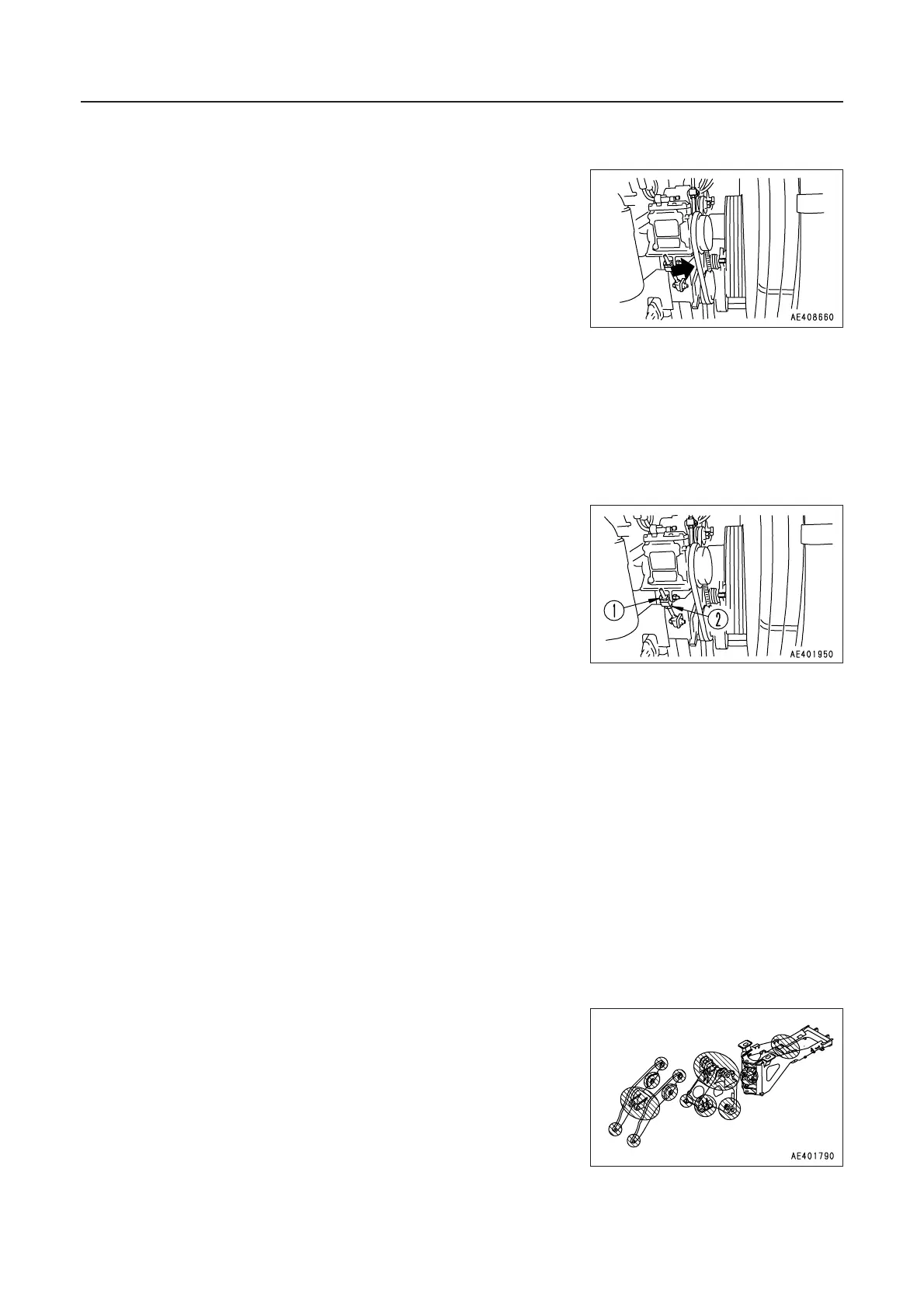

Adjusting

1. Loosen locknut 1.

2. Turn adjustment nut 2 to adjust so that the belt tension is the

specified value.

‡ V-belt tension

Deflection when cheking: 12.5 – 16.5 mm (0.5 – 0.7 in)

(98.1 N (10 kgf))

Deflection when replacing: 9 – 12.5 mm (0.355 – 0.5 in)

(98.1 N (10 kgf))

3. Check each pulley for damage and wear of the V-groove, and

check the V-belt for wear. Be particularly careful to check that

the V-belt does not contact the bottom of the V-groove.

4. If the V-belt is elongated and there is no more allowance for

adjustment, or if the belt is cut or cracked, replace it with a new

belt.

5. After adjusting, tighten lock nut 1.

6. After replacing the V-belt, operate the machine for one hour,

then check and adjust again.

24.6.6 CHECK FRAME AND BOOM

1. Wash the frame and boom so that the check can be carried out

easily.

2. Check all parts of the frame and boom for damage.

In particular, check the colored part in the diagram, and repair

if any cracks or other damage are found. For details of the method

of repair, please contact your Komatsu distributor.

Loading...

Loading...