5-23

31. HANDLING AUTO-GREASING SYSTEM

3. Method of bleeding air from pressure switch

This work shall be performed by two persons.

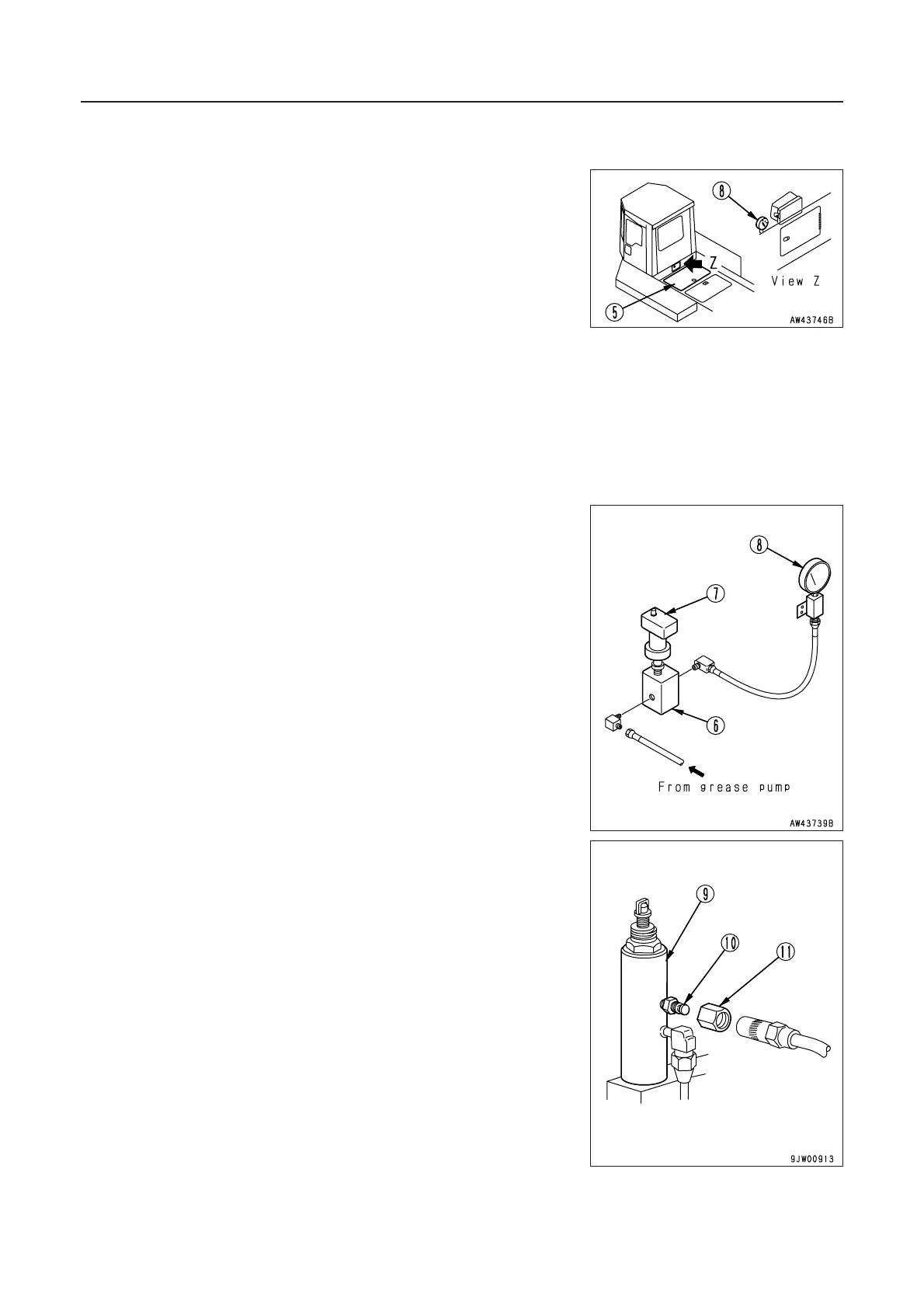

1) Open transmission inspection cover 5 at the rear of the cab.

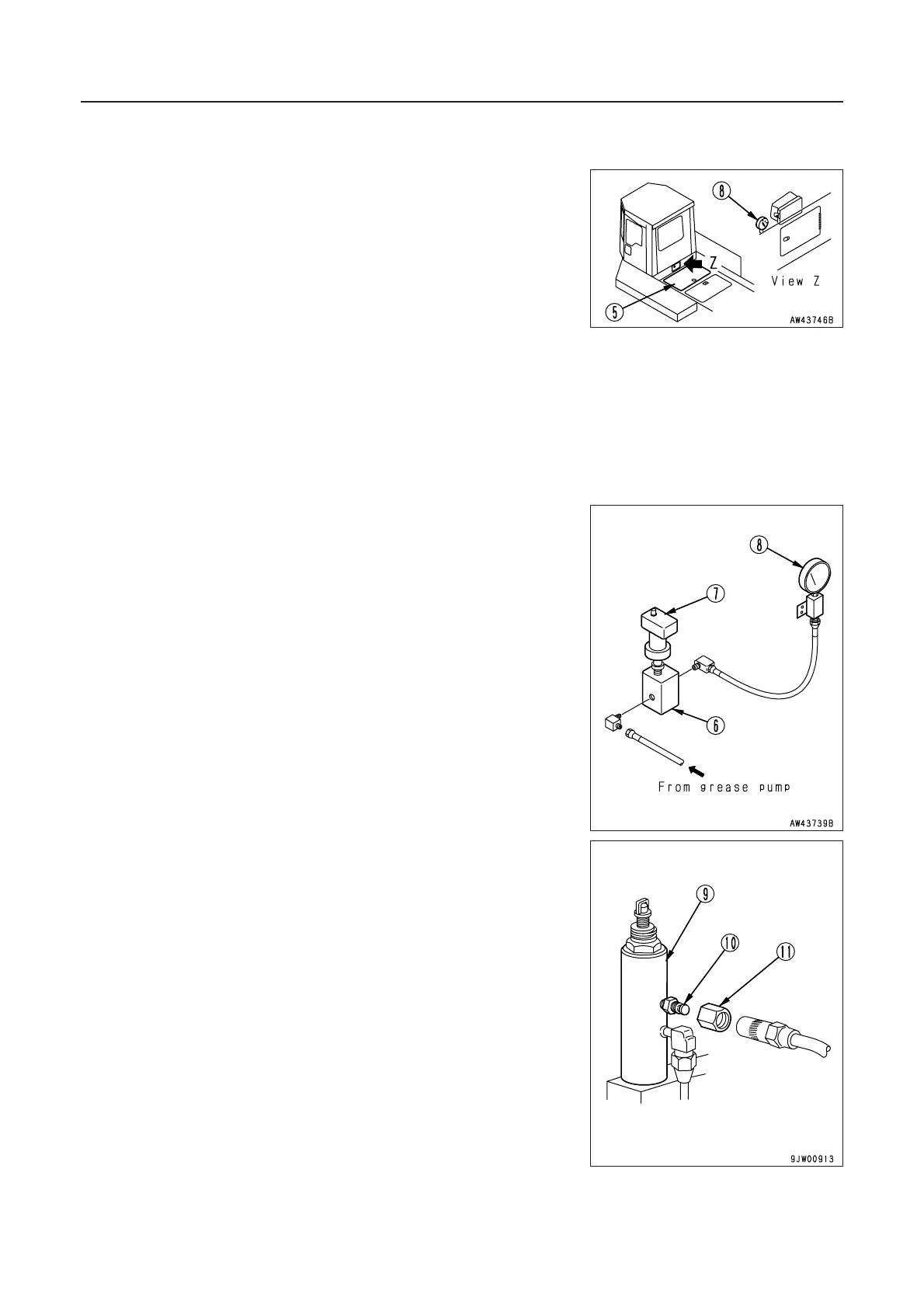

One person removes pressure switch 7 from block 6, then

stays there.

2) The other person presses the auto-greasing switch to start

the grease pump.

3) Discharge the grease containing air (milky white in many

cases) from the block 6. If normal grease comes out, stop

the grease pump.

4) Install pressure switch 7 to block 6. (Check that grease is

not leaking.)

4. Method of bleeding air from supply line

This work shall be performed by two persons.

1) One person removes supply line pressure gauge 8 from

block 6, then stays there.

2) The other person presses the auto-greasing switch to start

the grease pump.

3) Discharge the grease containing air (milky white in many

cases) from the block 6. If normal grease comes out, stop

the grease pump.

4) Install pressure gauge 8 to block 6. (Check that grease is

not leaking.)

NOTICE

If air is left in the circuit, the grease pressure will not rise to the

specified level or will take a long time to rise to the specified level,

and the injector will not work normally.

5. Filling branch lines (Injector - Pin) with grease

Remove cap A of filler fitting 0 of injector 9, then fill the all

branch lines with grease by using a hand grease gun.

Loading...

Loading...