.

OPERATION

TROUBLES AND ACTIONS

TROUBLES AND ACTIONS

RUNNING OUT OF FUEL

When starting the engine again after running out of fuel, fill with fuel, then bleed the air from the fuel system before

starting the engine.

Procedure for Bleeding Air

1.

Fill the fuel tank with fuel (to the position where the float is at the

highest position).

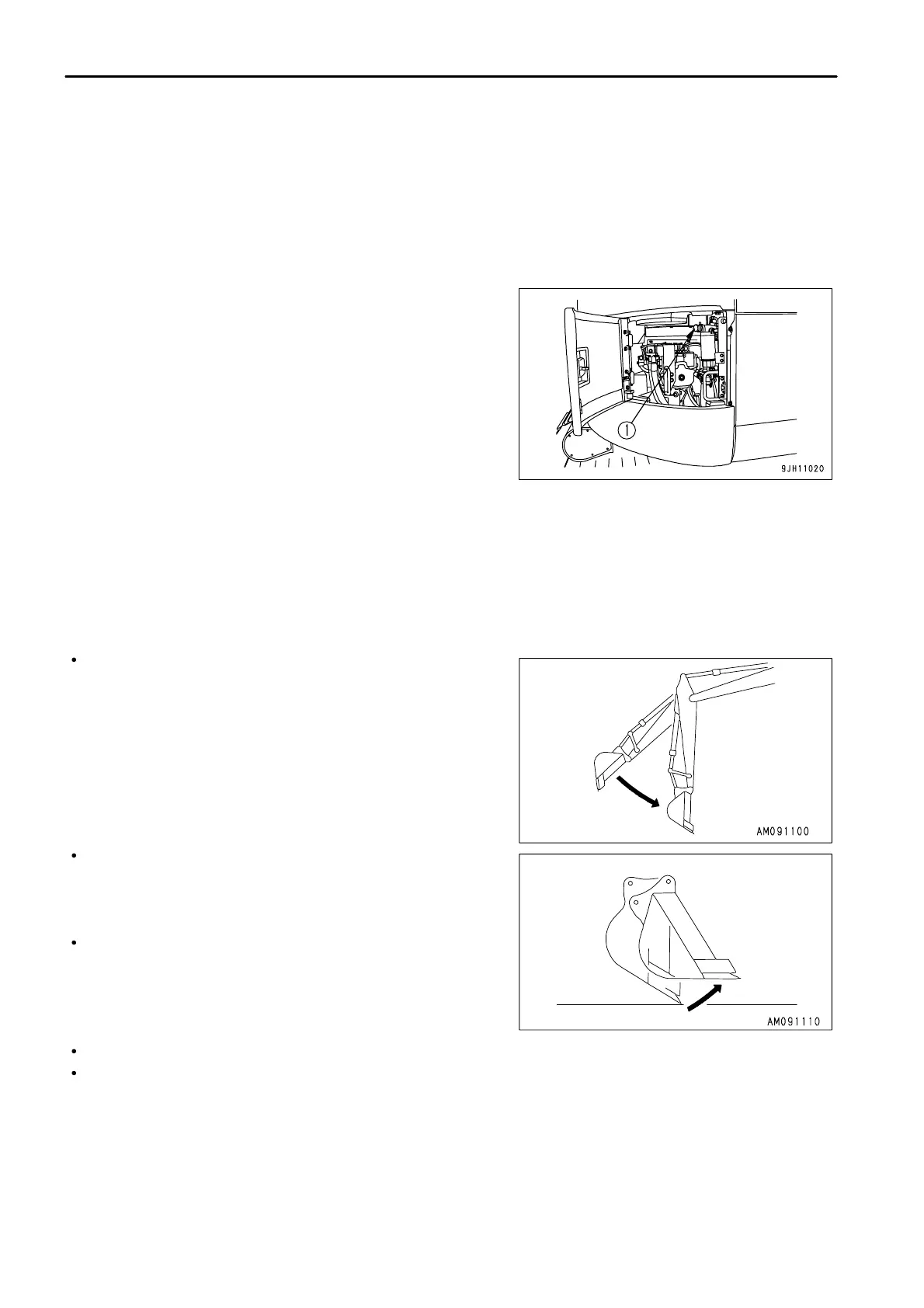

2. Open the rear door at the right of the machine.

3.

Loosen the knob of feed pump (1), pull it out, then pump it in

and out until the movement becomes heavy.

REMARK

It is not necessary to remove the plug at the top of the fuel pre-filter

and fuel main filter.

4.

Push in the knob of feed pump (1) and tighten it.

5. Turn the key in the starting switch to the START position and start the engine.

When doing this, do not crank the starting motor continuously for more than 20 seconds. If the engine does not

start, wait for at least 2 minutes, then try again. Perform this operation a maximum of 4 times.

PHENOMENA THAT ARE NOT FAILURES

Note that the following phenomena are not failures:

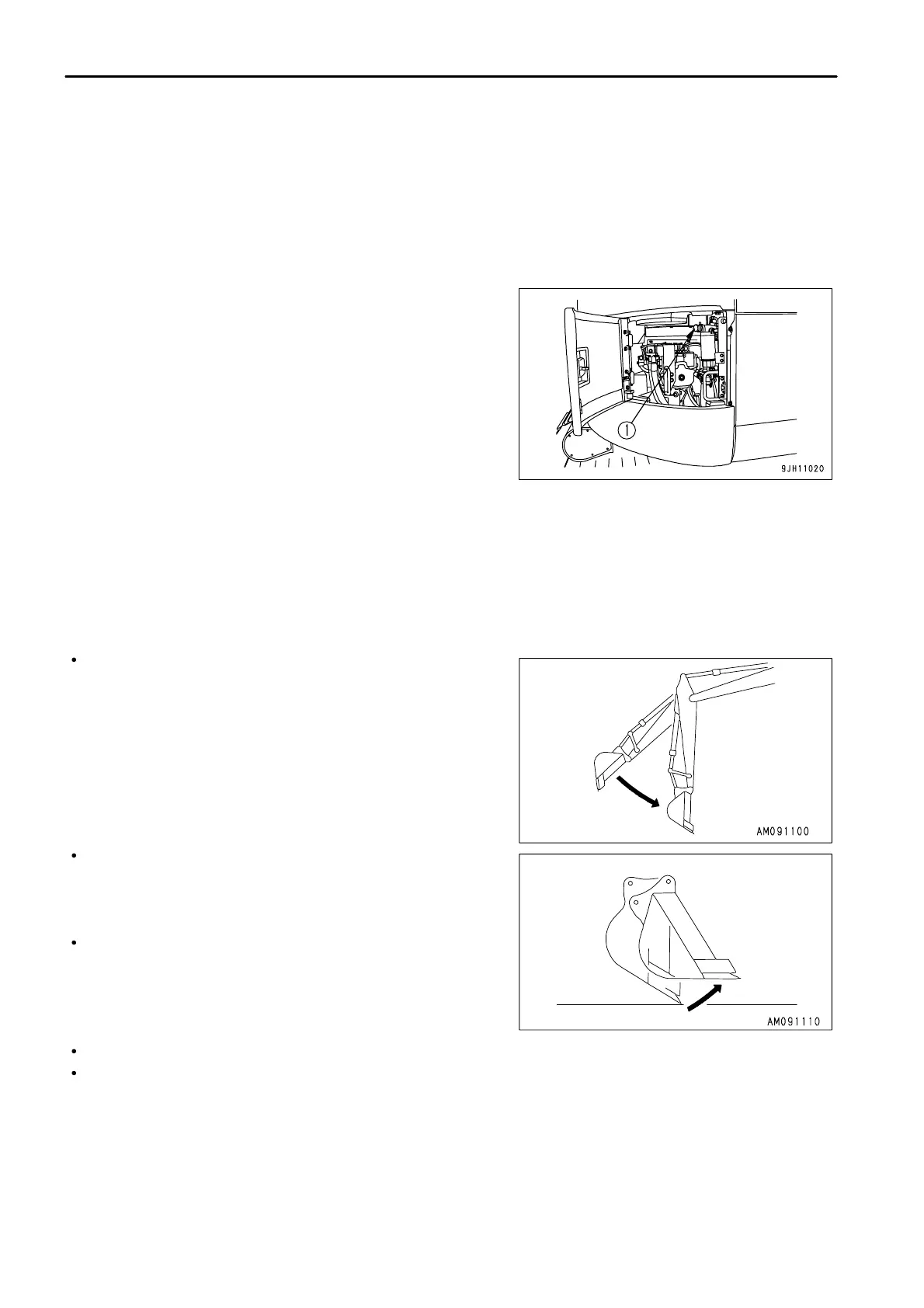

When the arm control lever is operated to the IN position and the

work equipment is lowered under no load from a high position,

the arm speed will drop momentarily when the arm is more or

less at the vertical position.

When the bucket control lever is operated to the CURL position

and the work equipment is lowered under no load from a high

position, the bucket speed will drop momentarily when the

bucket teeth are more or less at the horizontal position.

The bucket or arm will fluctuate by itself during heavy-duty

digging operations.

When starting or stopping the swing, noise will be emitted from the brake valve.

When going down a steep slope at low speed, a noise will be emitted from the travel motor brake valve.

3 - 146

Loading...

Loading...