.

MAINTENANCE

MAINTENANCE SCHEDULE

MAINTENANCE SCHEDULE

If the machine is equipped with a hydraulic breaker, the maintenance schedule for some parts will be different. For

details, see "MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER (PAGE 4-17)" to confirm the correct

maintenance schedule when carrying out maintenance.

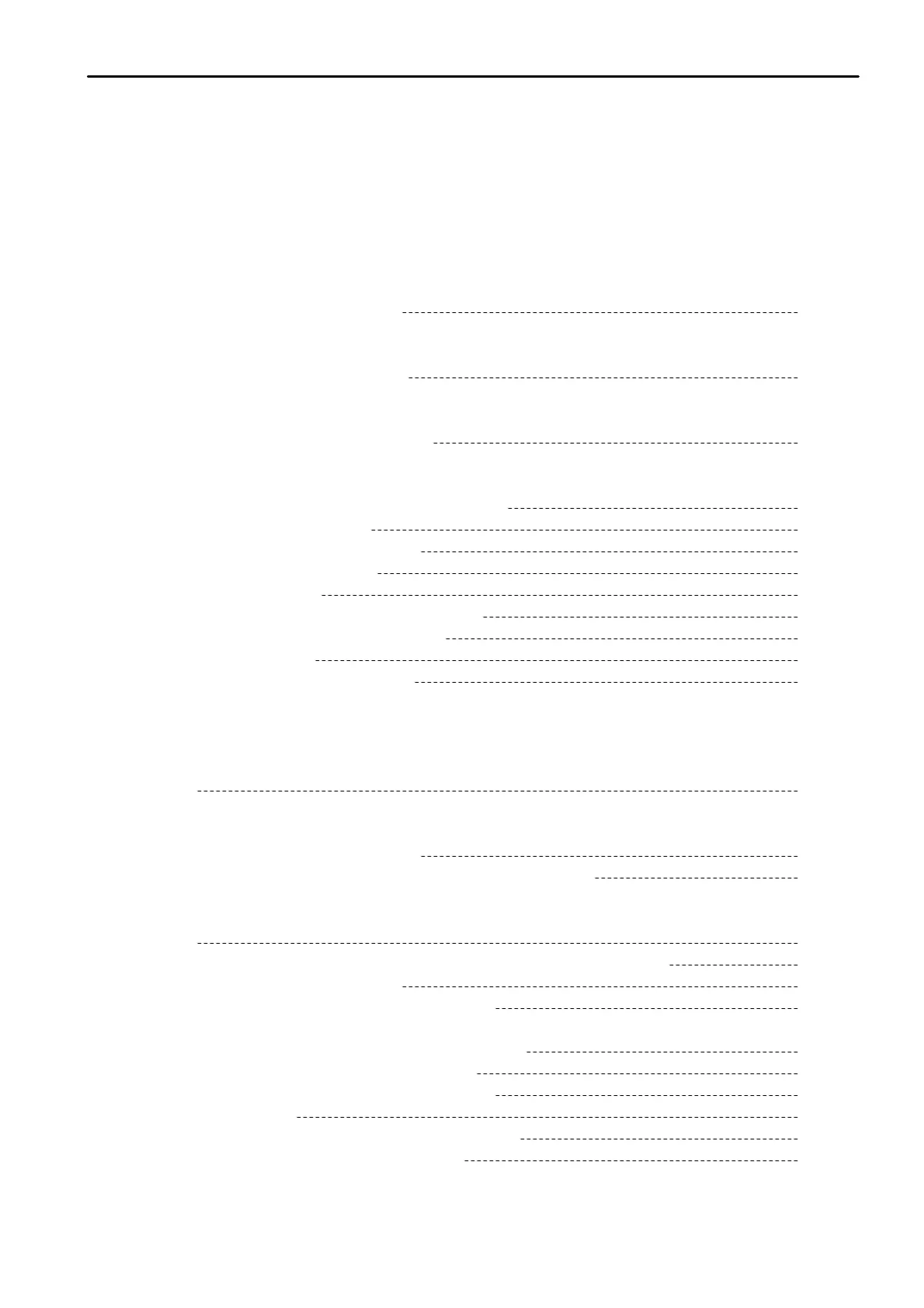

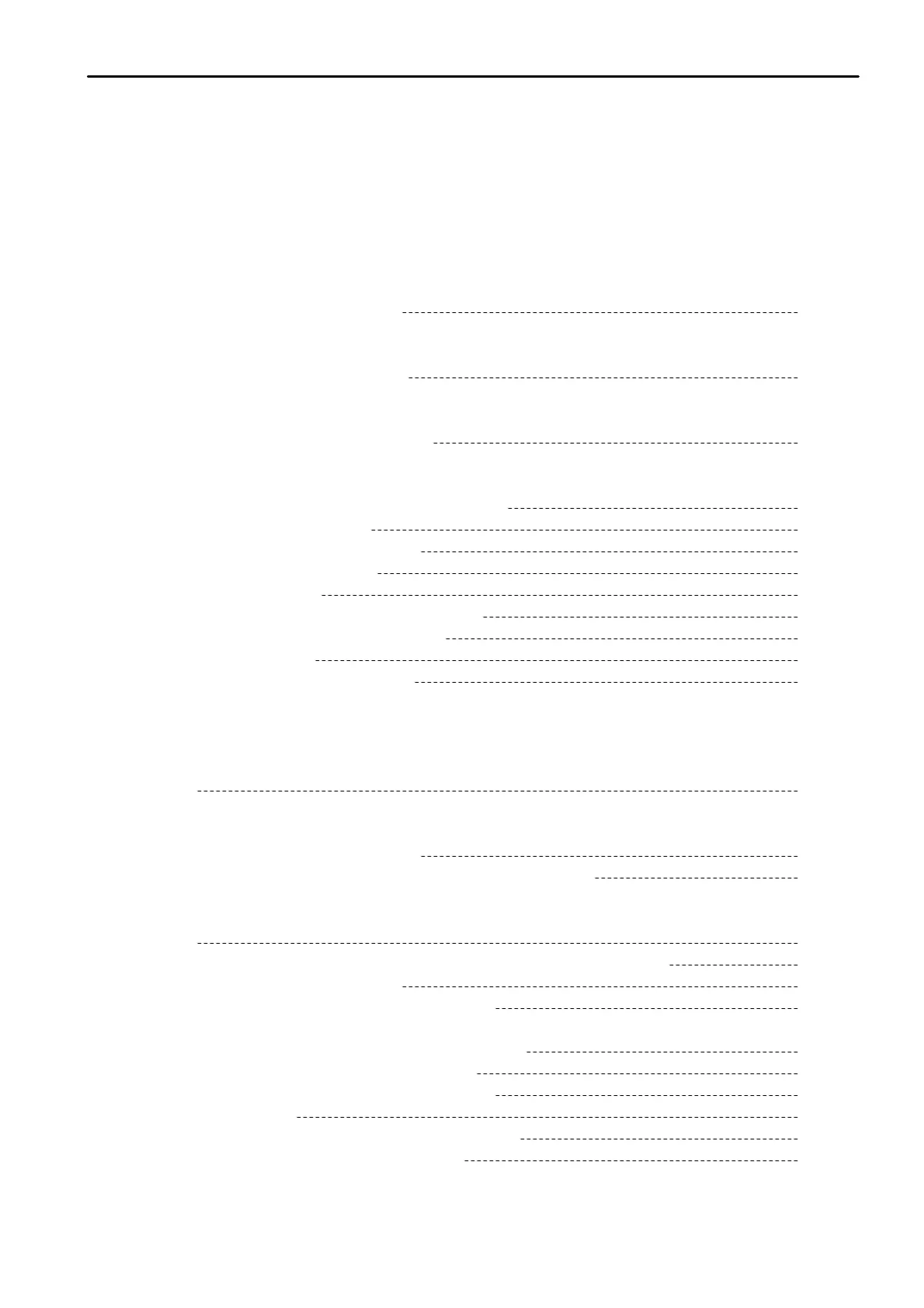

MAINTENANCE SCHEDULE CHART

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

REPLACE FUEL PRE-FILTER CARTRIDGE 4- 49

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)

REPLACE FUEL MAIN FILTER CARTRIDGE 4- 61

INITIAL 1000 HOURS MAINTENANCE (ONLY AFTER THE FIRST 1000 HOURS)

CHECK ENGINE VALVE CLEARANCE, ADJUST 4- 70

WHEN REQUIRED

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT 4- 19

CLEAN INSIDE OF COOLING SYSTEM 4- 26

CHECK AND TIGHTEN TRACK SHOE BOLTS 4- 29

CHECK AND ADJUST TRACK TENSION 4- 30

ADJUST BUCKET CREARANCE 4- 32

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID 4- 33

CHECK AND MAINTENANCE AIR CONDITIONER 4- 34

WASHING WASHABLE FLOOR 4- 35

BLEEDING AIR FROM HYDRAULIC SYSTEM 4- 38

CHECKS BEFORE STARTING

EVERY 100 HOURS MAINTENANCE

LUBRICATING 4- 41

EVERY 250 HOURS MAINTENANCE

CHECK LEVEL OF BATTERY ELECTROLYTE 4- 42

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST 4- 44

EVERY 500 HOURS MAINTENANCE

LUBRICATING 4- 45

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE 4- 47

REPLACE FUEL PRE-FILTER CARTRIDGE 4- 49

CHECK SWING PINION GREASE LEVEL, ADD GREASE 4- 51

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS, AFTERCOOLER FINS, FUEL

COOLER FINS, AND AIR CONDITIONER CONDENSER FINS 4- 52

CLEAN AIR CONDITIONER FRESH/RECIRC FILTERS 4- 53

REPLACE BREATHER ELEMENT IN HYDRAULIC TANK 4- 55

LUBRICATE SWING CIRCLE 4- 56

CHECK OIL LEVEL IN SWING MACHINERY CASE, ADD OIL 4- 56

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL 4- 57

4 - 15

Loading...

Loading...