20-110

PC58UU-3

b

TESTING AND ADJUSTING TRACK SHOE TENSION

TESTING AND ADJUSTING

TRACK SHOE TENSION

Testing

1. Run the engine at low idling and move the

machine forward by the length of track on the

ground and stop slowly.

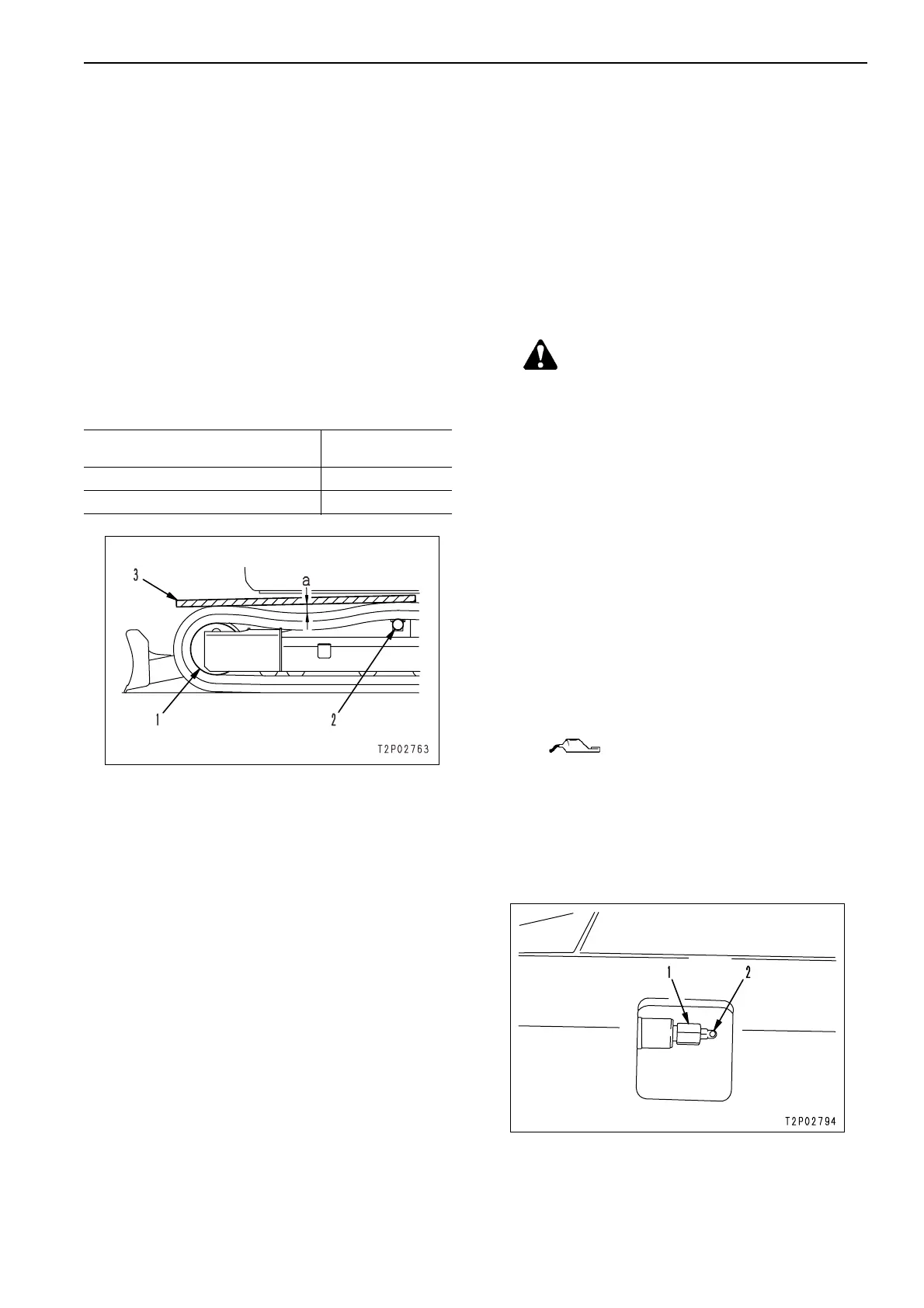

2. Place straight-edge (3) over idler (1) and carrier

roller (2).

3. Measure the maximum distance between the

top of the track and the underside of the

straight-edge.

• If the standard slack (a) is in the following

range, the shoe tension is normal.

Adjusting

★

If the standard track shoe tension is abnormal,

adjust according to the following procedure.

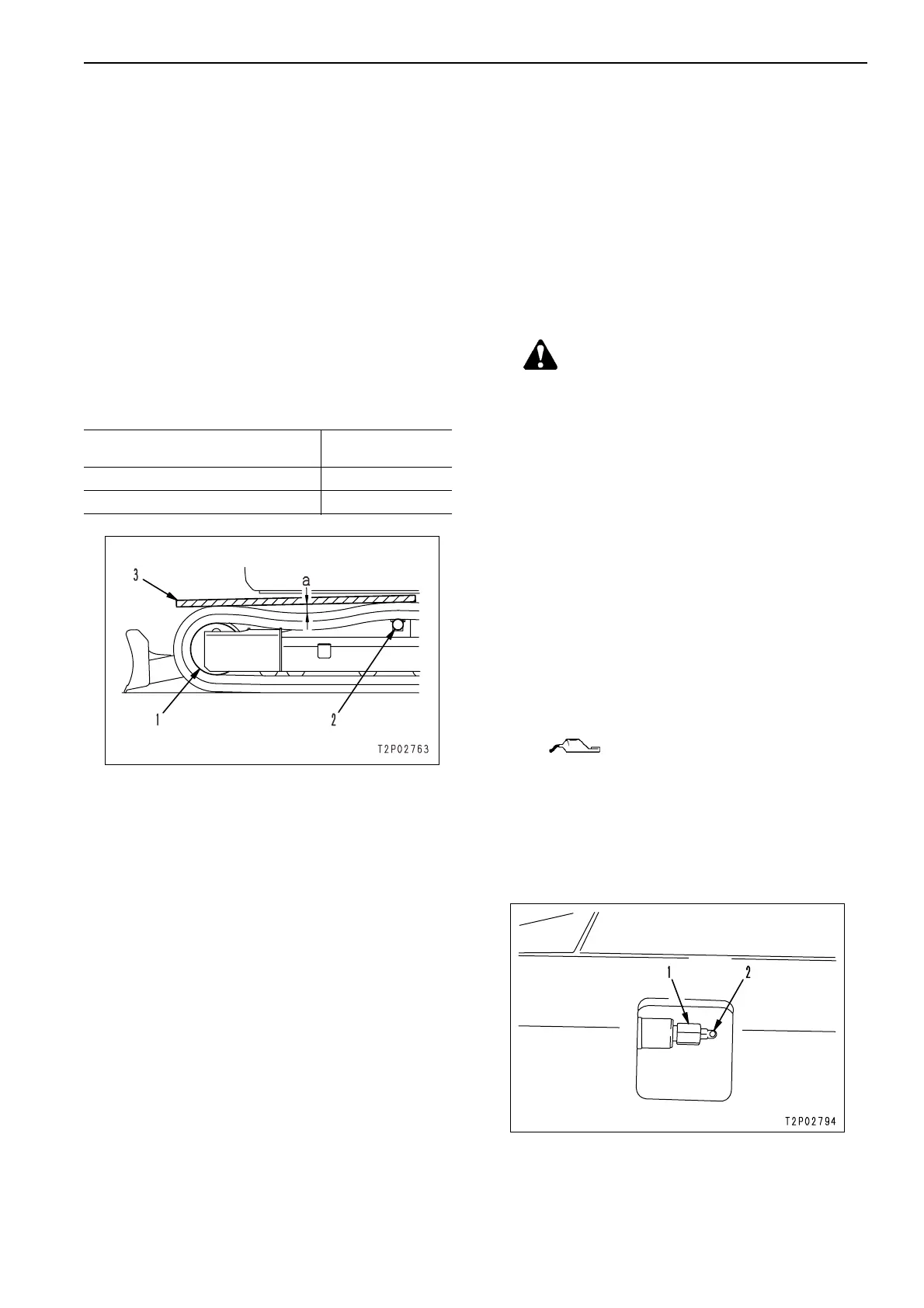

1. When tension is too high

1) Loosen valve (1) gradually to discharge

grease.

★

If the grease is not discharged sufficiently,

move the machine slowly forward and in

reverse.

2) To check that the track shoe tension is nor-

mal, run the engine at low idling and move

the machine forward by the length of track

on the ground and stop slowly.

3) Test the track shoe tension again. If it is still

abnormal, adjust it again.

2. When tension is too low

1) Supply grease through grease fitting (2).

★

If the track shoe tension is not tensed

well, move the machine slowly forward

and in reverse.

2) To check that the track shoe tension is nor-

mal, run the engine at low idling and move

the machine forward by the length of track

on the ground and stop slowly.

3) Test the track shoe tension again. If it is still

abnormal, adjust again.

Specification

Standard slack

(a)

Road liner, steel shoe 10 ~ 30 mm

Rubber shoe 1 ~ 3 mm

Do not loosen the valve more

than 1 turn since the internal

high-pressure grease may spout

out.

Grease fitting:

Grease (G2-LI)

Loading...

Loading...