20-112

PC58UU-3

b

TESTING AND ADJUSTING

HYDRAULIC PRESSURE IN WORK EQUIPMENT,

SWING, AND TRAVEL CIRCUITS

TESTING AND ADJUSTING

HYDRAULIC PRESSURE IN

WORK EQUIPMENT, SWING,

AND TRAVEL CIRCUITS

Measuring

★

Oil temperature for measurement: 45 - 55 °C

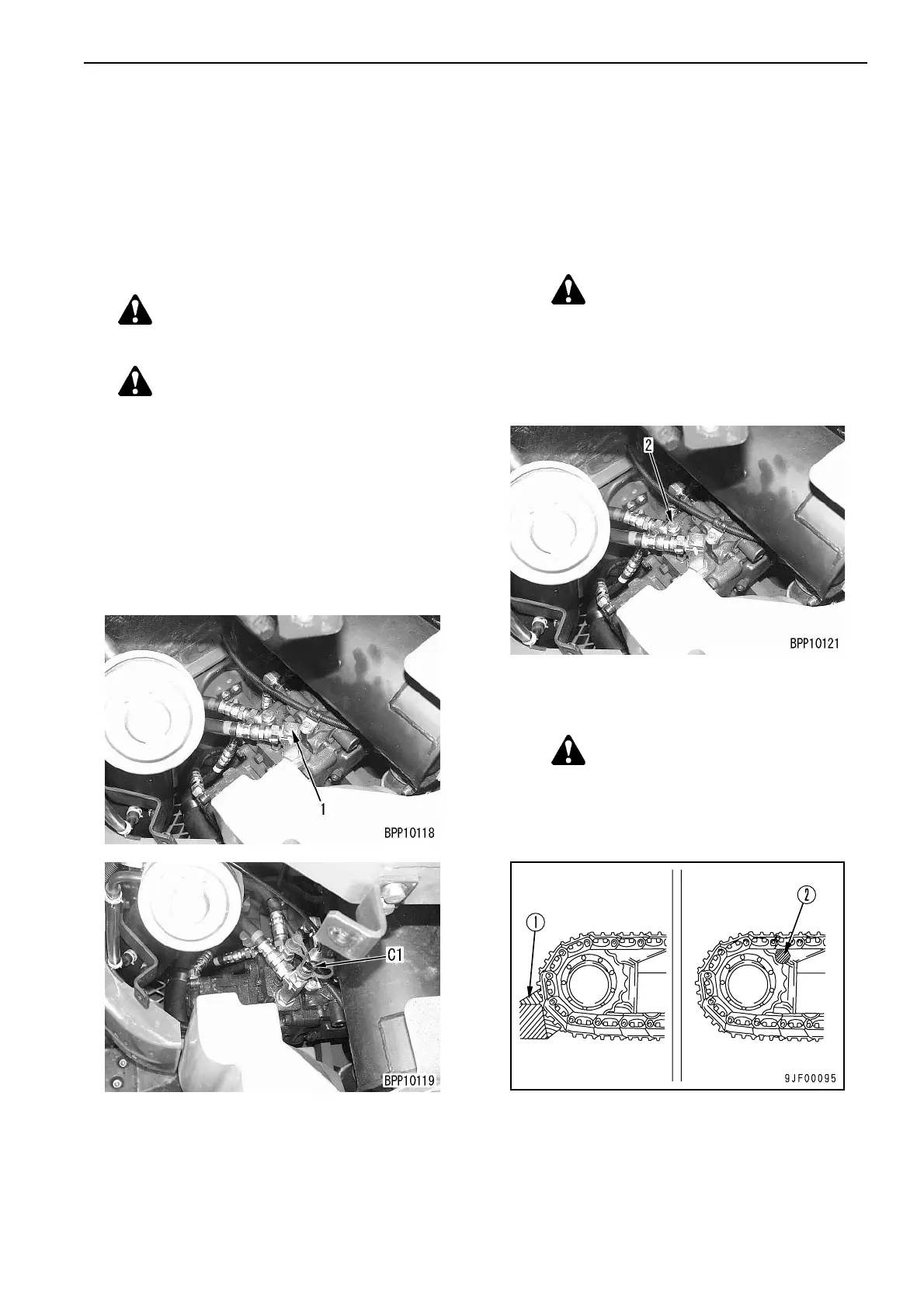

1. Measuring unload oil pressure

1) Remove oil pressure pickup plug (1) (10

mm, P = 1.25) and install oil pressure gauge

C1 (39.2 MPa {400 kg/cm²}).

2) Run the engine at full throttle and set all

control levers in neutral and measure the

oil pressure.

2. Measuring work equipment relief pressure

1) Remove oil pressure pickup plug (1) (10

mm, P = 1.25) and install oil pressure gauge

C1 (39.2 MPa {400 kg/cm²}).

2) Run the engine at full throttle and relieve

each actuator and measure the oil pressure

at this time.

3. Measuring travel circuit relief pressure

1) Remove oil pressure pickup plug (1) and (2)

(10 mm, P = 1.25) and install oil pressure

gauge C1 (39.2 MPa {400 kg/cm²}).

2) Run the engine at full throttle and relieve

the travel pump and measure the oil pres-

sure at this time.

Before removing the oil pressure

pickup plug, release the residual

pressure from hydraulic tank.

After installing the oil pressure

gauge, pressurize the hydraulic

tank. For details, see Pressuriz-

ing hydraulic tank.

Move each cylinder to the

stroke end.

Put block

b

against the

grouser of the track shoe or

put block

c

between the

sprocket and frame to lock

the track shoe.