PC58UU-3

20-115

b

TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE

Adjusting

1. Adjusting LS valve

★

If the LS differential pressure is abnormal,

adjust the LS valve according to the follow-

ing procedure.

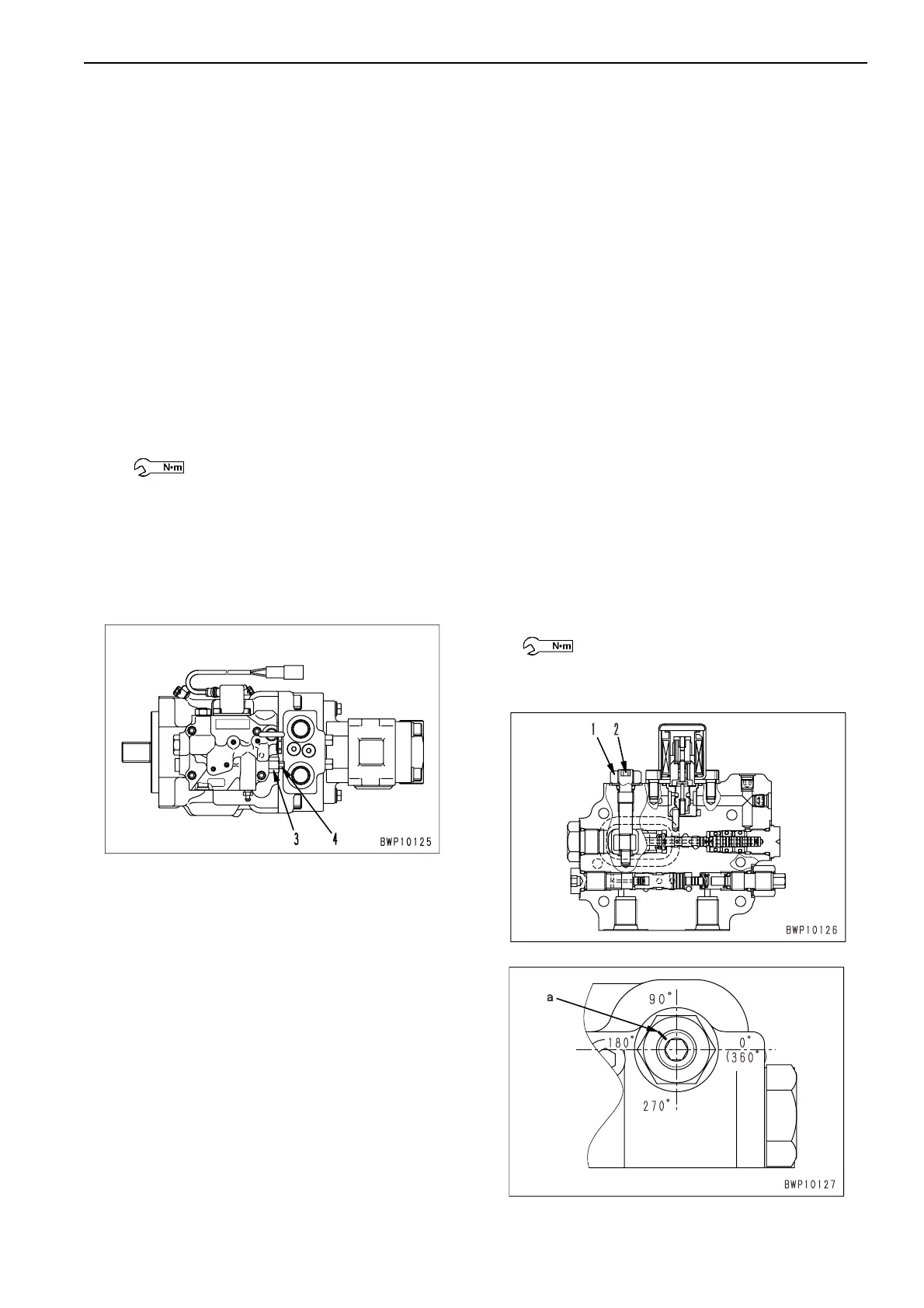

1) Loosen locknut (3) and rotate adjustment

screw (4).

★

As the adjustment screw is

•

rotated clockwise, the pressure is

heightened, and if it is

•

rotated counterclockwise, the pres-

sure is lowered.

★

Quantity of adjustment per turn of

adjustment screw:

1.27 MPa {13 kg/cm²}

2) After adjusting, tighten locknut (3).

★

After adjusting, measure the LS differ-

ential pressure, referring to Measuring

described above.

★

When loosening or tightening the lock-

nut, secure adjustment screw (4) with a

spanner so that it will not be dragged.

ADJUSTING PC VALVE

★

When the load is increased, [the engine speed

may lower] or [the engine speed may be nor-

mal and working speed may lower]. If this trou-

ble occurs and the pump discharge and LS

differential pressure are normal, adjust the

pump PC valve according to the following pro-

cedure.

★

In which direction the adjustment screw should

be rotated to increase the torque is unknown.

Accordingly, monitor the engine speed when

rotating the adjustment screw.

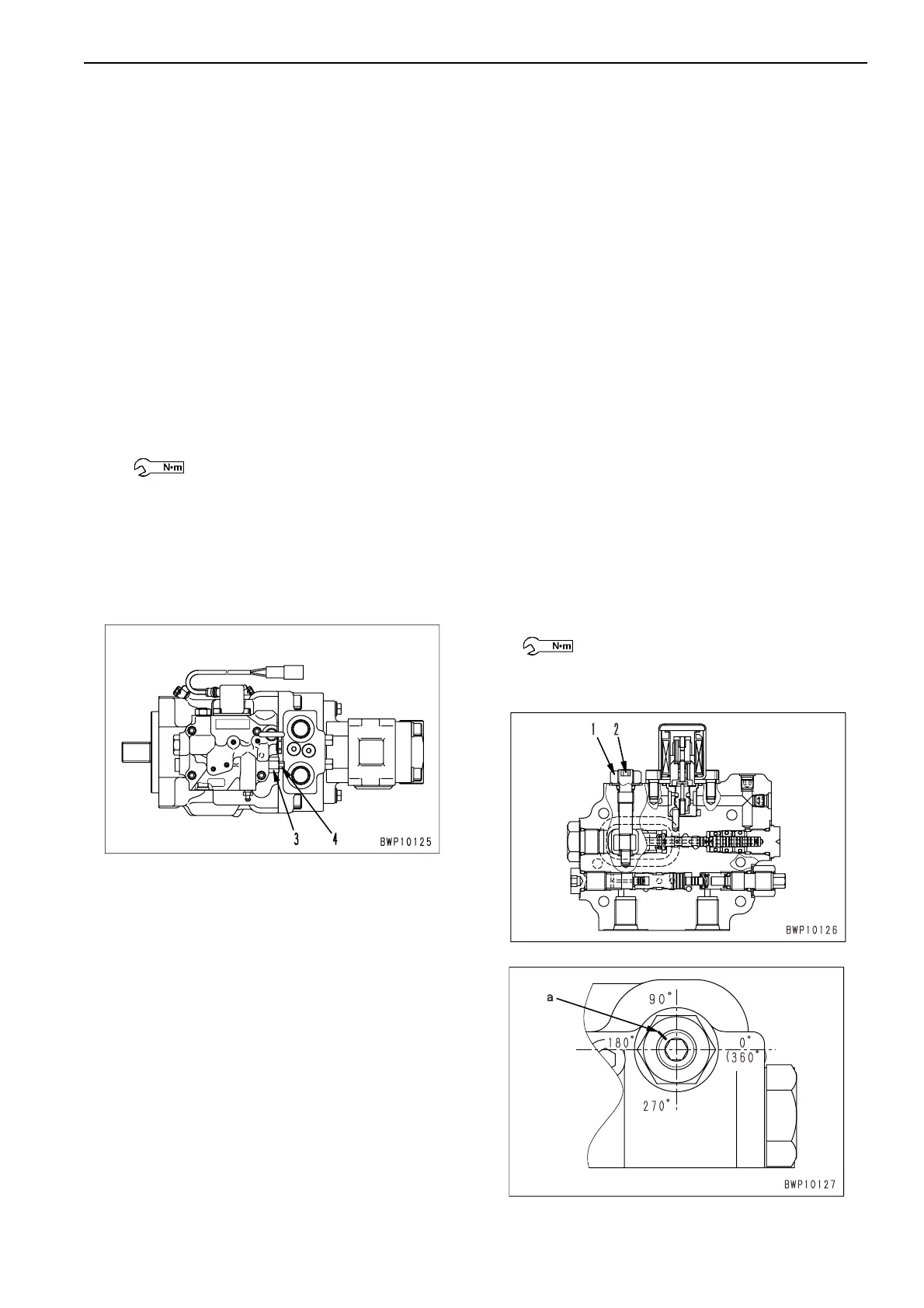

1. Loosen locknut (1) and rotate adjustment screw

(2).

If [the work equipment speed is low], turn

adjustment screw (2) to the [counterclockwise]

(to increase the pump absorption torque). If

[the engine speed lowers], turn adjustment

screw (2) to the [clockwise] (to reduce the pump

absorption torque). Limit the adjustment range

to ± 180° from the position for shipping.

★

Since the position for shipping is not

punched, make match marks (a) before

adjusting.

2. After adjusting, tighten locknut (1).

Locknut:

27.4 ~ 34.3 Nm {2.8 ~ 3.5 kgm}

Locknut:

27.4 ~ 34.3 Nm {2.8 ~ 3.5 kgm}

Loading...

Loading...