OPERATION OPERATION

3-94

ADJUSTING WORK EQUIPMENT POSTURE 3

WARNING

q Stop the machine on flat ground and put blocks in

front and behind the wheels.

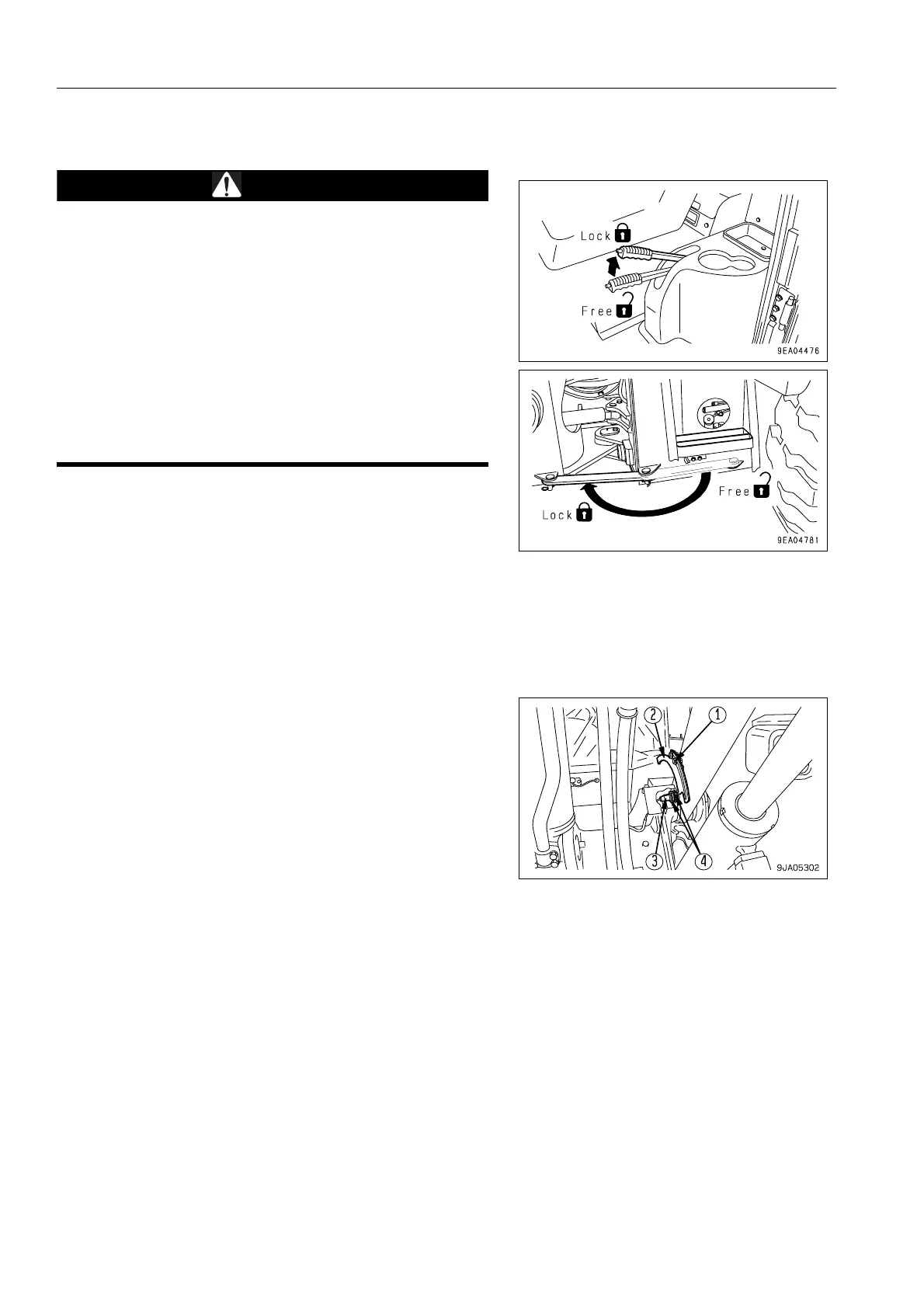

q Set parking brake lever to the LOCK position.

q Secure the front and rear frames with the safety bar.

q Always attach the warning tag to the work equipment

control lever.

q Do not go under the work equipment when the arm is

raised. To support the work equipment securely, use a

strong support that can withstand the weight of the

work equipment and prevent the arm coming from

down.

The boom kickout makes it possible to set the bucket so that it

automatically stops at the desired lifting height (lift arm higher

than horizontal) and the bucket positioner makes it possible to

set the bucket so that it automatically stops at the desired dig-

ging angle. The setting can be adjusted to match the working

conditions.

ADJUSTING BOOM KICKOUT 3

1. Raise the bucket to the desired height, set the lift arm con-

trol lever at HOLD, then set the safety lever to the LOCK

position and stop the engine.

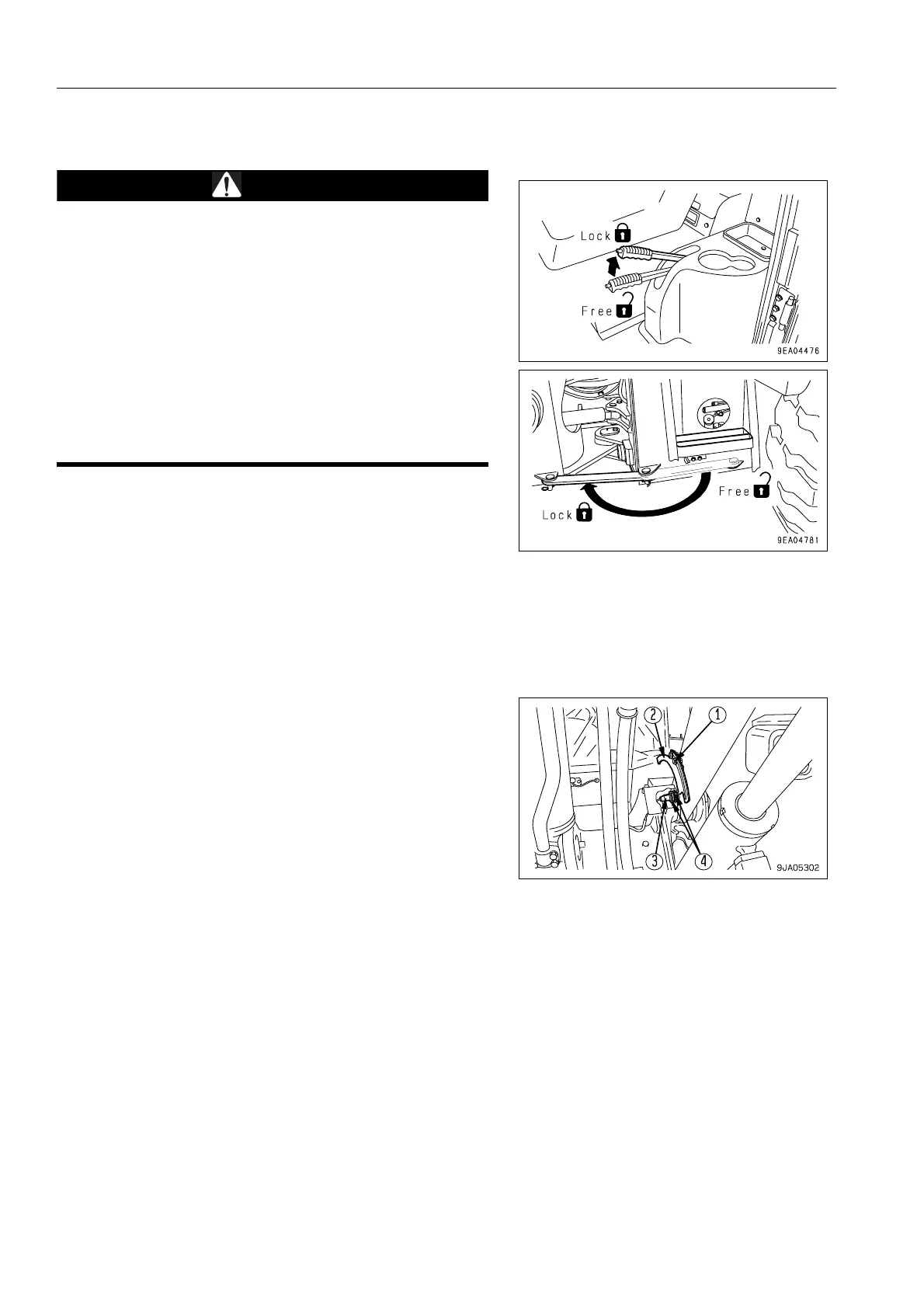

2. Loosen two bolts (1), and adjust plate (2) so that the bot-

tom edge is in line with the center of the sensing surface of

proximity switch (3). Then tighten the bolts to hold the

plate in position.

3. Loosen two nuts (4) to make a clearance of 3 to 5 mm

(0.118 to 0.197 in) between plate (2) and the sensing sur-

face of proximity switch (3). Then tighten the nuts to hold

in position.

Tightening torque: 14.7 to 19.6 N·m (1.5 to 2.0 kgf·m, 10.8

to 14.5 lbft)

4. After adjusting, start the engine and operate the lift arm control lever. Check that the lever is automatically

returned to HOLD when the bucket reaches the desired height.

Loading...

Loading...