.

SAFETY

GENERAL PRECAUTIONS

KEEP MACHINE CLEAN

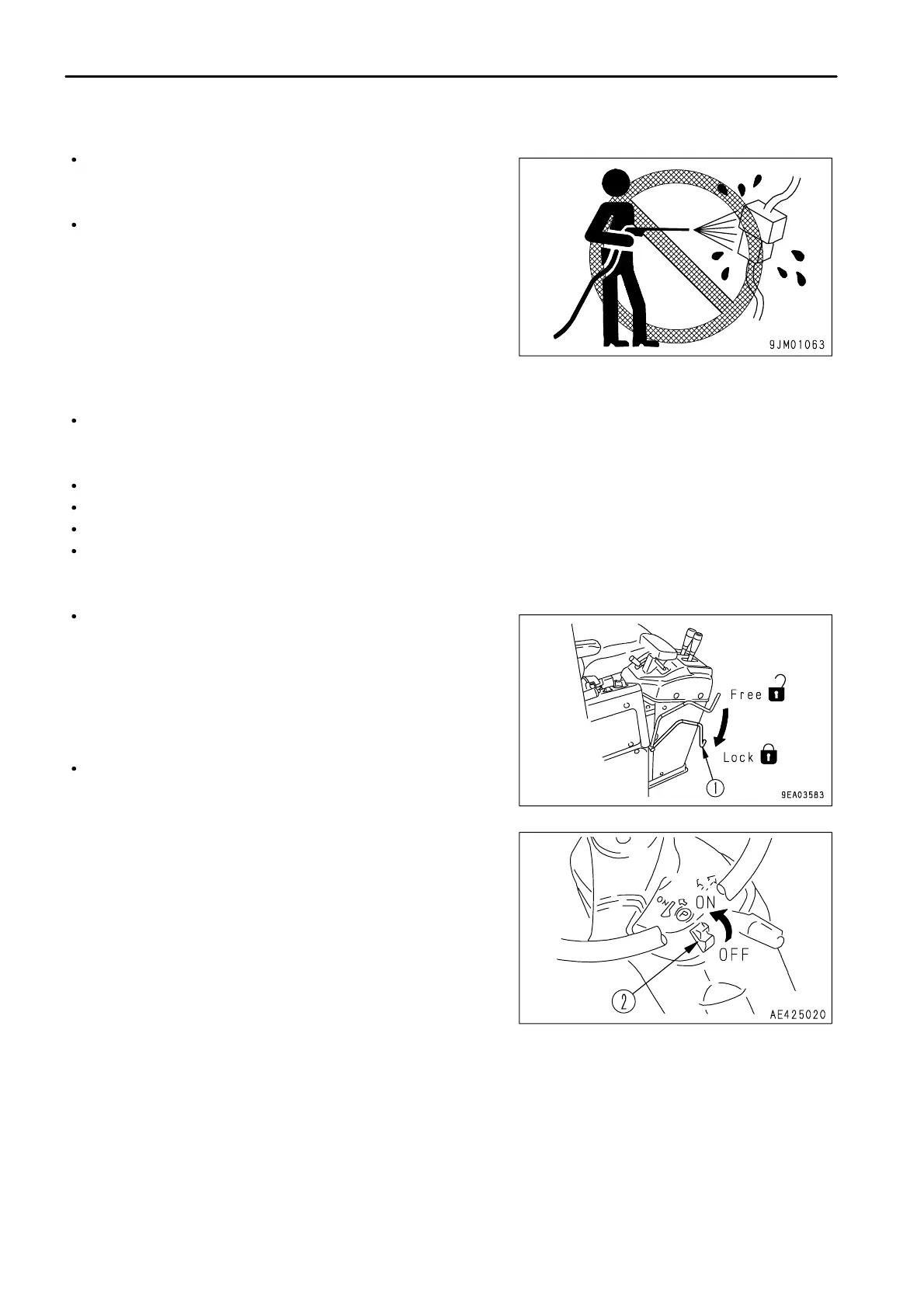

If water gets into the electrical system, there is a hazard that it

will cause malfunctions or misoperation. Do not use water or

steam to wash the electrical system (sensors, connectors).

If inspection and maintenance is carried out when the machine

is still dirty with mud or oil, there is a hazard that you will slip and

fall, or that dirt or mud will get into your eyes. Always keep the

machine clean.

INSIDE OPERATOR'S COMPARTMENT

When entering the operator's compartment, always remove all mud and oil from the soles of your shoes.

If you operate the pedal with mud or oil affixed to your shoes, your foot may slip and this may cause a serious

accident.

Do not leave parts or tools lying around the operator's compartment.

Do not stick suction pads to the window glass. Suction pads act as a lens and may cause fire.

Do not use cellular telephones inside the operator's compartment when driving or operating the machine.

Never bring any dangerous objects such as flammable or explosive items into the operator's compartment.

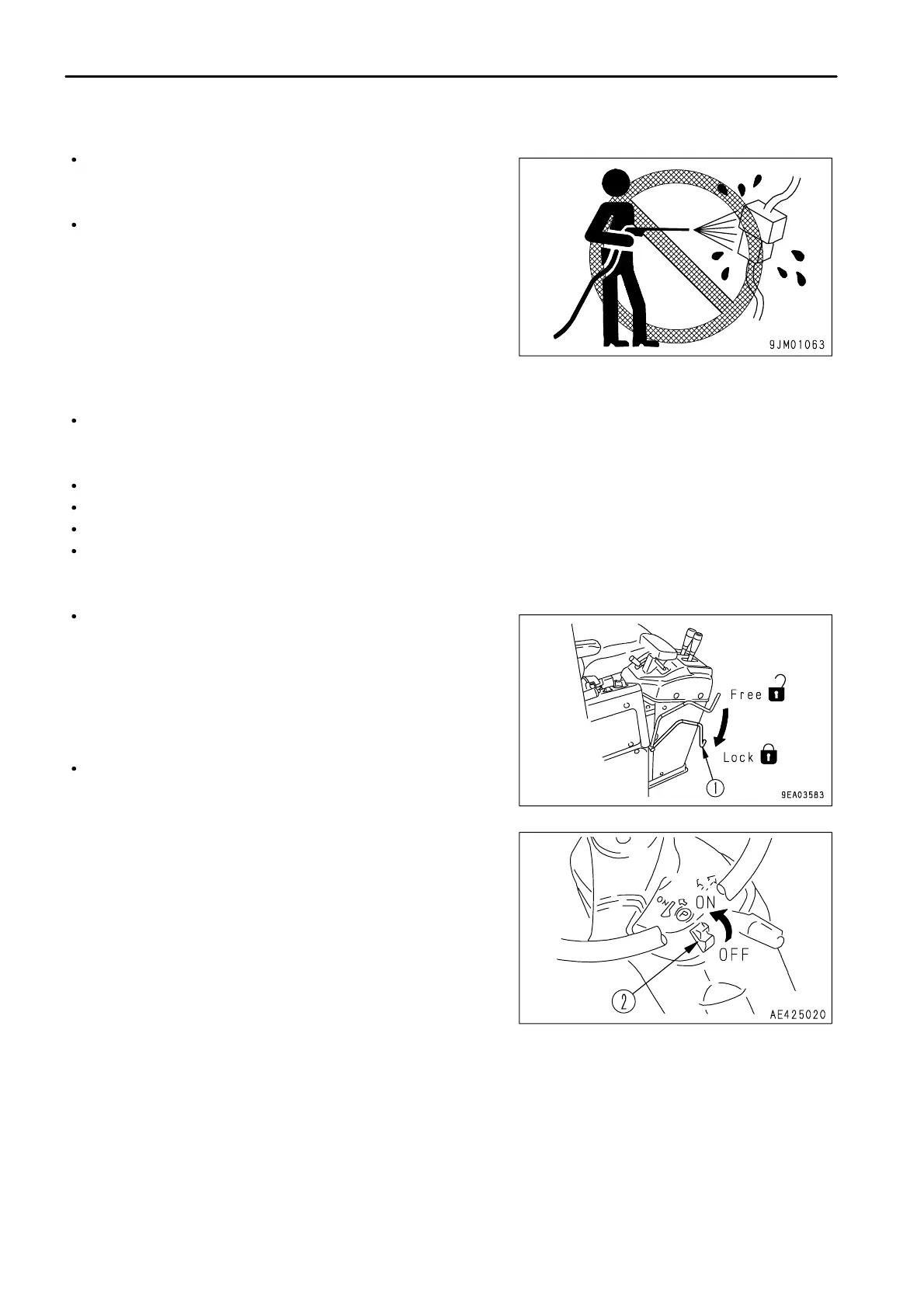

ALWAYS APPLY LOCK WHEN LEAVING OPERATOR'S SEAT

Before standing up from the operator's seat to adjust the

operator's seat, always lower the work equipment, set work

equipment lock lever (1) to the LOCK position and parking brake

switch (2) to the ON position, then stop the engine.

If you accidentally touch the travel or swing lever when they are

not locked. The work equipment may suddenly move and cause

serious injury.

When leaving the machine, always lower the work equipment to

the ground, set work equipment lock lever (1) to the LOCK

position and parking brake switch (2) to the ON position, then

stop the engine. Lock all places and always take the key with

you and leave it in the specified location.

2 - 12

Loading...

Loading...