.

SAFETY

PRECAUTIONS FOR MAINTENANCE

SAFETY

PRECAUTIONS FOR MAINTENANCE

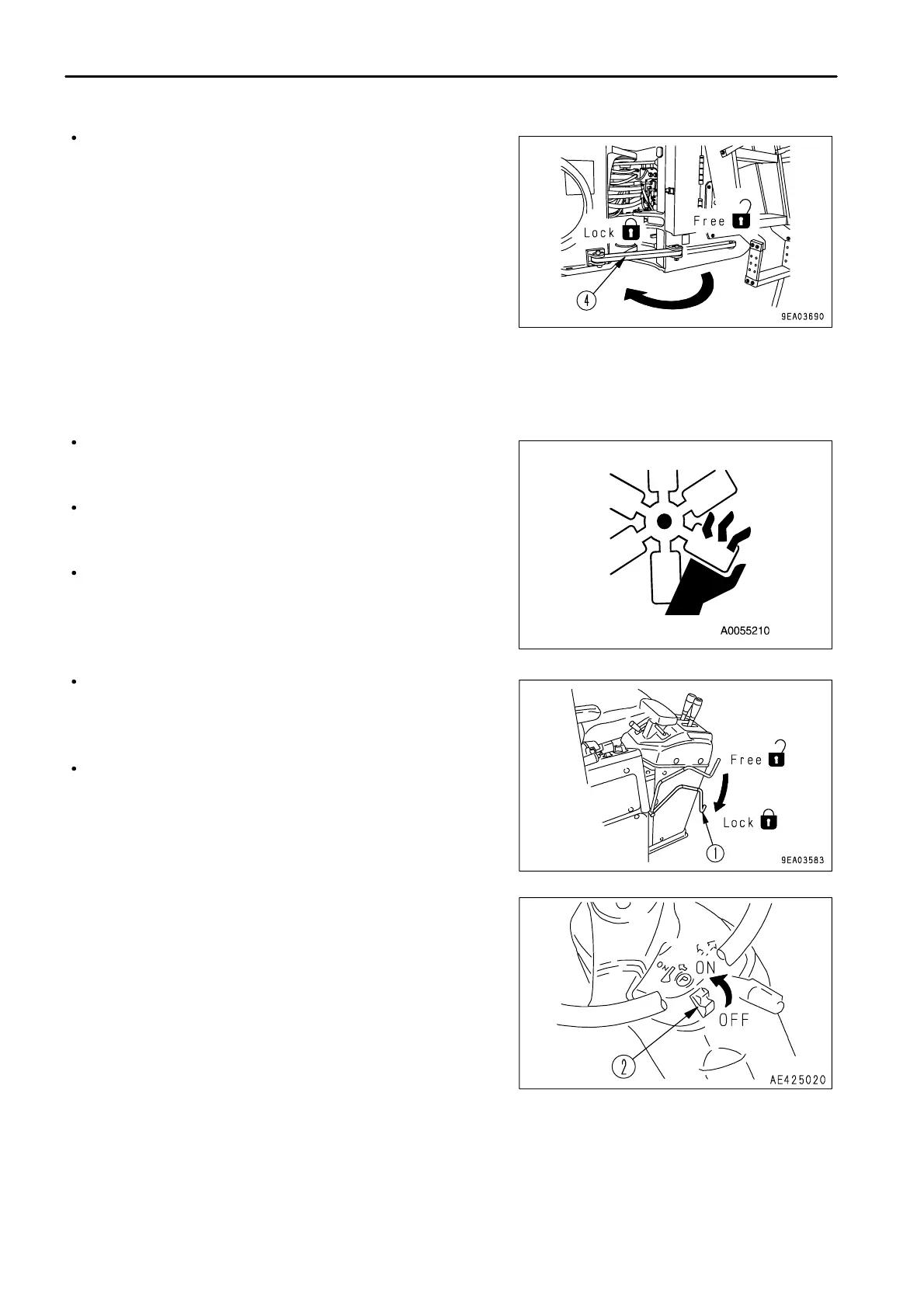

Lock the front and rear frames with frame lock bar (4).

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

To prevent personal injury, do not carry out maintenance with the engine running. If maintenance must be carried

out with the engine running, carry out the operation with at least two workers and do as follows.

One worker must always sit in the operator's seat and be ready

to stop the engine at any time. All workers must maintain

contact with the other workers.

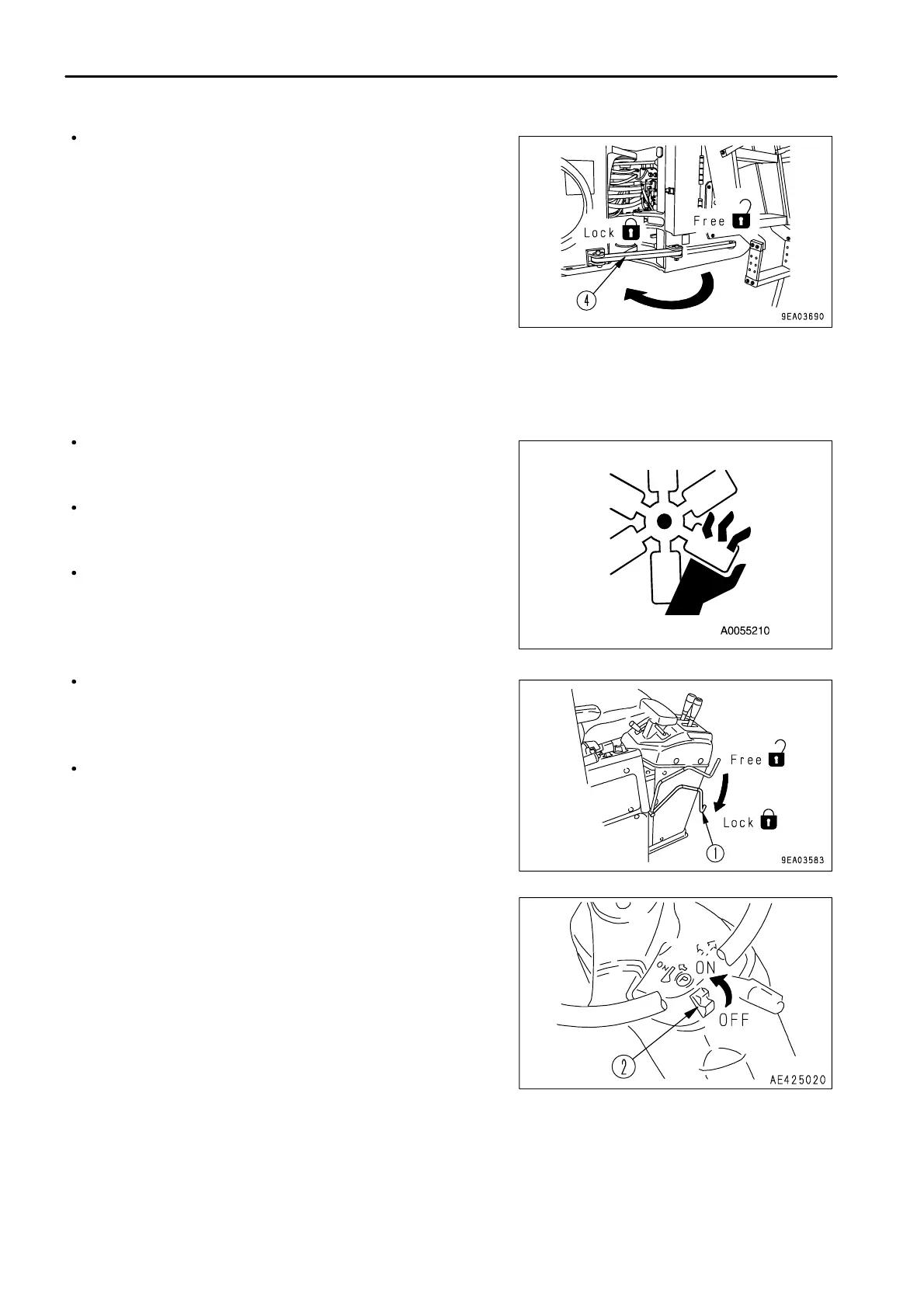

When carrying out operations near the fan, fan belt, or other

rotating parts, there is a hazard of being caught in the parts, so

be careful not to come close.

Never drop or insert tools or other objects into the fan or fan belt.

Parts may break or be sent flying.

Set work equipment lock lever (1) to the LOCK position to

prevent the work equipment from moving.

Turn parking brake switch (2) to the ON position to apply the

parking brake.

Do not touch any control levers. If any control lever must be

operated, give a signal to the other workers to warn them to

move to a safe place.

INSPECTION AND MAINTENANCE AFTER TURNING E.C.S.S. SWITCH OFF

For machines equipped with a E.C.S.S. lower the bucket to the ground, turn the E.C.S.S. switch OFF, and stop the

engine before starting inspection or maintenance. NEVER turn the switch ON during inspection or maintenance.

2 - 34

Loading...

Loading...