MAINTENANCE EVERY 1000 OPERATING HOURS

7-59

MAINTENANCE EVERY 1000 OPERATING HOURS

All maintenance operations to be performed after 10, 50, 100,

250 and 500 hours of operation fall also into this maintenance

category.

COOLING SYSTEM, EXCHANGING COOLANT AND CLEANING THE

SYSTEM

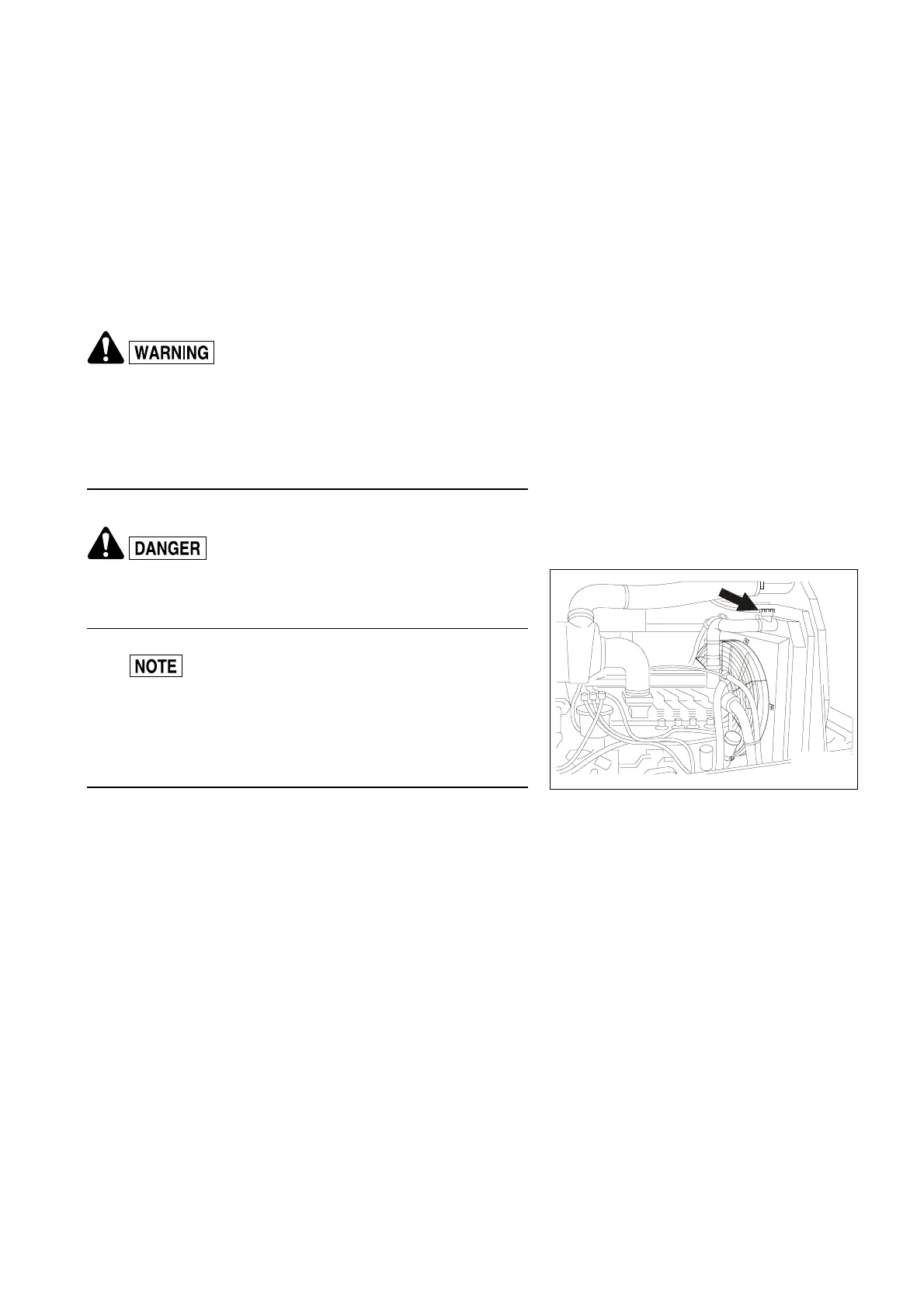

• Danger of being burnt! The coolant is under pressure if

the engine is hot. Hot coolant may squirt out during open-

ing.

Check the coolant level only after the engine has suffi-

ciently cooled down. Open the cover of the radiator (ar-

row) by turning it slowly so that the pressure can escape.

• Danger of fire! Antifreeze may ignite at the hot engine!

Wait until the engine has cooled down, before refilling an-

tifreeze.

☞

• The coolant must be exchanged after max. of two years.

• While preparing the coolant, make sure to adhere to the

prescribed mixing proportions to ensure a freezing pro-

tection up to -34.6°F (-37°C)! This is also valid for areas

with moderate climate.

The coolant has to consist of 50 vol.% coolant additive and

50 vol.% water. Only monoethylene glycol and dieethylene gly-

col are permitted as coolant additives which are both contained

in commercially available standard coolants.

If the water contains too much lime, the cooling system may be

impaired. In this case, use a mixture of potable water and dis-

tilled or deionized water.

75_202

Loading...

Loading...