TRANSMISSION AND TORQUE CONVERTER CD3340B/YB4411

7-14

Published 04/07/2015 Control # 569-00

Troubleshooting (Electrical)

System Operation

Each powershift transmission is provided with electrical

safety locks which inhibit inadvertent operation of the

machine while in an unsafe condition.

When the parking brake is ENGAGED the machine is

prevented from moving by dumping oil in the transmissions’

oil system to the internal oil reservoir. No oil is directed to any

of the drive mechanisms, thereby inhibiting machine

movement. When DISENGAGED the machine will only start

when the shift control lever is in the NEUTRAL position.

Change of machine travel direction is accomplished by

moving the shift control lever, located on the steering

column, from Neutral (center) position up to the FORWARD

position or down to the REVERSE position. Change of speed

range is accomplished by rotating the shift control handle

COUNTERCLOCKWISE to increase the travel speed range

or CLOCKWISE to decrease the travel speed range.

Movement of the shift control lever and rotation of the shift

control handle energizes combinations of solenoid valves

through the ECU, which are connected to two shafts located

in the transmission (See Figure 7-1).

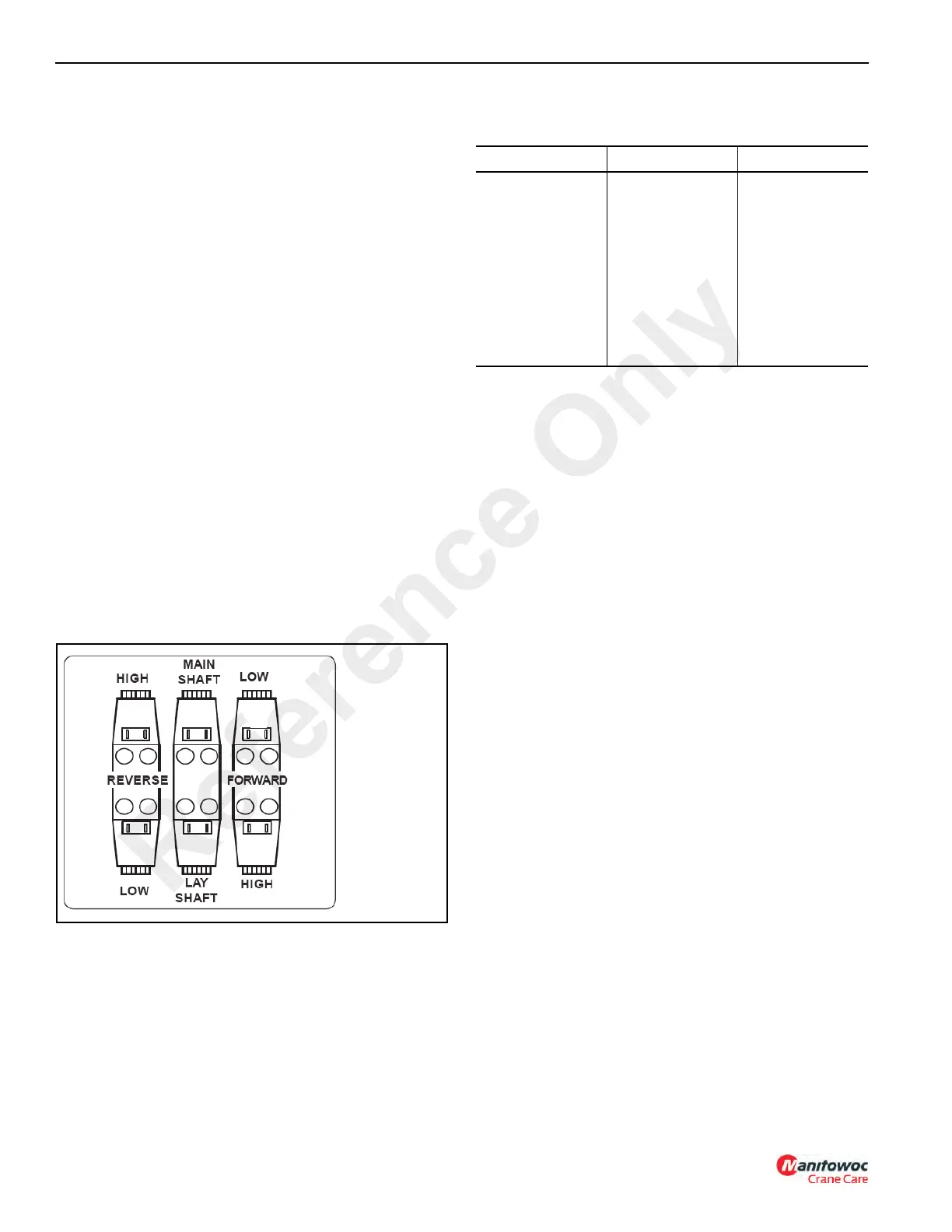

Transmissions are furnished with six solenoid valves (RH,

RL, MS, LS, FL and FH) See arrangement in Figure 7-7. Two

of the solenoid valves control speed ranges while the

remaining four control speed and the direction of travel.

The solenoids are controlled by the transmission Electronic

Control Unit (ECU) and are connected through the wire

harness.

The following table shows which solenoid valves are

energized for the four speeds and two directions of travel.

Table 7-1

Solenoid Valve Energizing Sequence

Electronic Control Unit (ECU)

The Electronic Control Unit (ECU) is designed to do two

things:

a. To control the selection of gears and direction of

travel.

b. To protect the gearbox from damage due to

incorrect use of the controls.

It is a microprocessor controlled unit which is mounted under

the dash in the operators’ cab. A wire harness connects the

ECU to the transmission harness, which connects to the

solenoids, the oil pressure switch and a speed sensor, on the

transmission. A second harness connects the unit to various

switches and selectors in the cab (See Figure 7-8).

The unit receives signals from the gear/direction and other

switches in the cab and operates the appropriate

transmission solenoids accordingly. Built-in software

prevents potentially damaging (and dangerous) selections

from being made. The control features provided by the ECU

software are listed below:

1. Downshift Inhibit - prevents too low of a gear being

selected for a given speed.

2. Kickdown - operated by a button on the shift lever in the

cab - changes down a gear (from 2nd, 3rd or 4th) for a

period of 6 seconds before reverting to the selected

gear.

3. Reverse Inhibit - prevents directional changes if the

speed is too high.

4. Neutral Start - the machine will only start with the shift

control handle in neutral, irrespective of gear selection

(speed) position.

Gear Direction Valves

First

Second

Third

Fourth

First

Second

Third

Fourth

Forward

Forward

Forward

Forward

Reverse

Reverse

Reverse

Reverse

FL and LS

FH and LS

FL and MS

FH and MS

RL and LS

RH and LS

RL and MS

RH and MS

Reference Only

Loading...

Loading...