GROVE 7-57

CD3340B/YB4411 TRANSMISSION AND TORQUE CONVERTER

Published 04/07/2015 Control # 569-00

Assembly

Visually inspect the friction and counter plates:

• Counter plates - light scoring/polishing is permissible,

plates that are flat, worn or heavily marked or scored

must be replaced with a new set.

• Friction Plates - the cross hatching should be clearly

visible, plates that are flat, have friction material damage

or scoring must be replaced with a new set.

DO NOT mix old and new plates. If a plate is damaged/worn

install a complete new set.

Needle roller bearings should slide into position freely, do not

bend or distort the cage to install. If the cage has been

distorted, install new bearings.

1. Install new O-ring (26) onto piston (25). Lubricate with oil

and then press piston fully into bore of housing (5).

2. Install inner pressure end plate (24). Make sure the teeth

are not aligned with the lubrication slots in the housing.

NOTE: The inner pressure end plate is 4 mm (0.157 in)

thick and should not be confused with the outer

pressure end plate which is either

6.0 mm (0.23 in) or 6.5 mm (0.25 in) thick.

3. Install one friction plate (22) followed by one counter

plate (23). Continue installing alternating friction and

counter plates. Finish with a friction plate.

4. Install pressure end plate (20). Make sure the teeth are

not aligned with lubricating slots in the housing. Do not

install shim (21) at this stage.

NOTE: A spring disc is not installed in this clutch pack.

5. Install clutch friction/counter plate retaining ring (19).

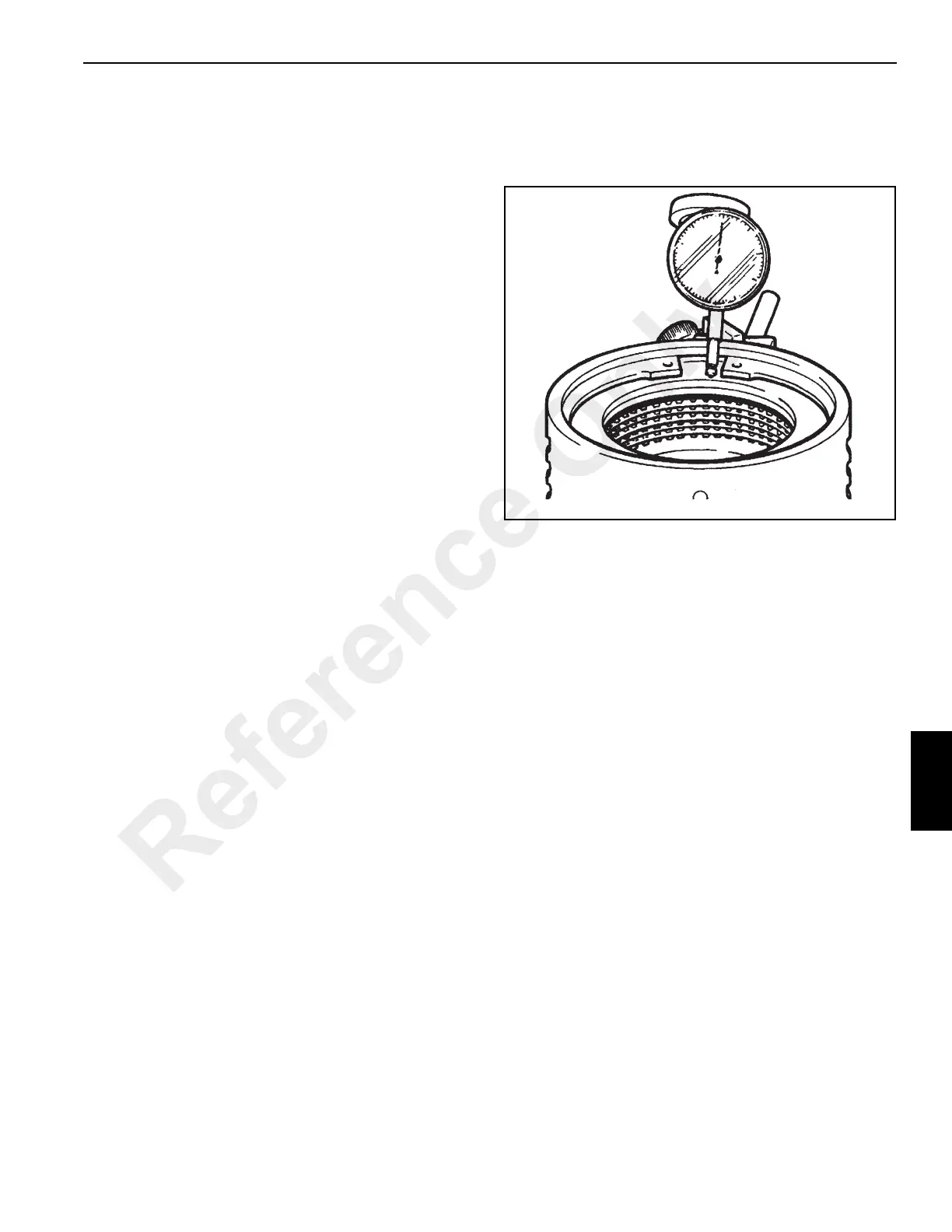

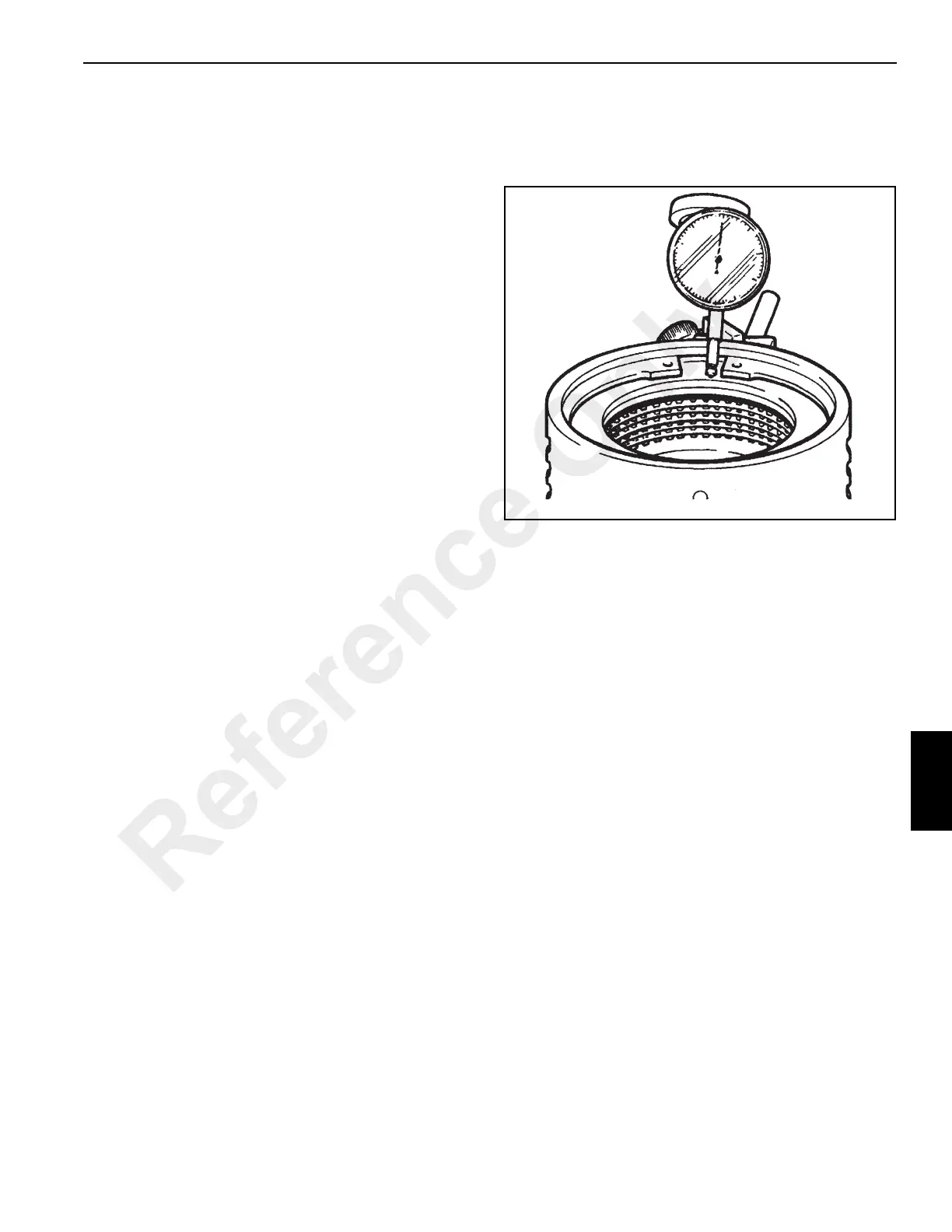

6. Using a dial test indicator as shown in Figure 7-79,

measure the end play of the pressure end plate. End

play should be 1.90 - 2.5 mm (0.075 - 0.098 in).

To adjust the end play, there is a choice between a 6.0 mm

(0.23 in) or a 6.5 mm (0.25 in) pressure end plate (20) with

either a shim (21) or extra counter plate (23) between

retaining ring (19) and pressure end plate (20).

7. Install needle roller thrust bearing (18) and thrust washer

(17).

8. Install two needle roller bearing (16).

9. Install gear and splined hub (12).

10. Install thin thrust washer (15) followed by needle roller

thrust bearing (14) and thrust washer (13).

11. Install retaining ring (11).

12. Install spring retaining plate (8).

13. Install two new O-rings (9 and 10) to the layshaft.

14. Install spring (7) and oil baffle (6).

Reference Only

Loading...

Loading...