AXLES/DRIVE SHAFTS/WHEELS AND TIRES CD3340B/YB4411

8-6

Published 04/07/2015 Control # 569-00

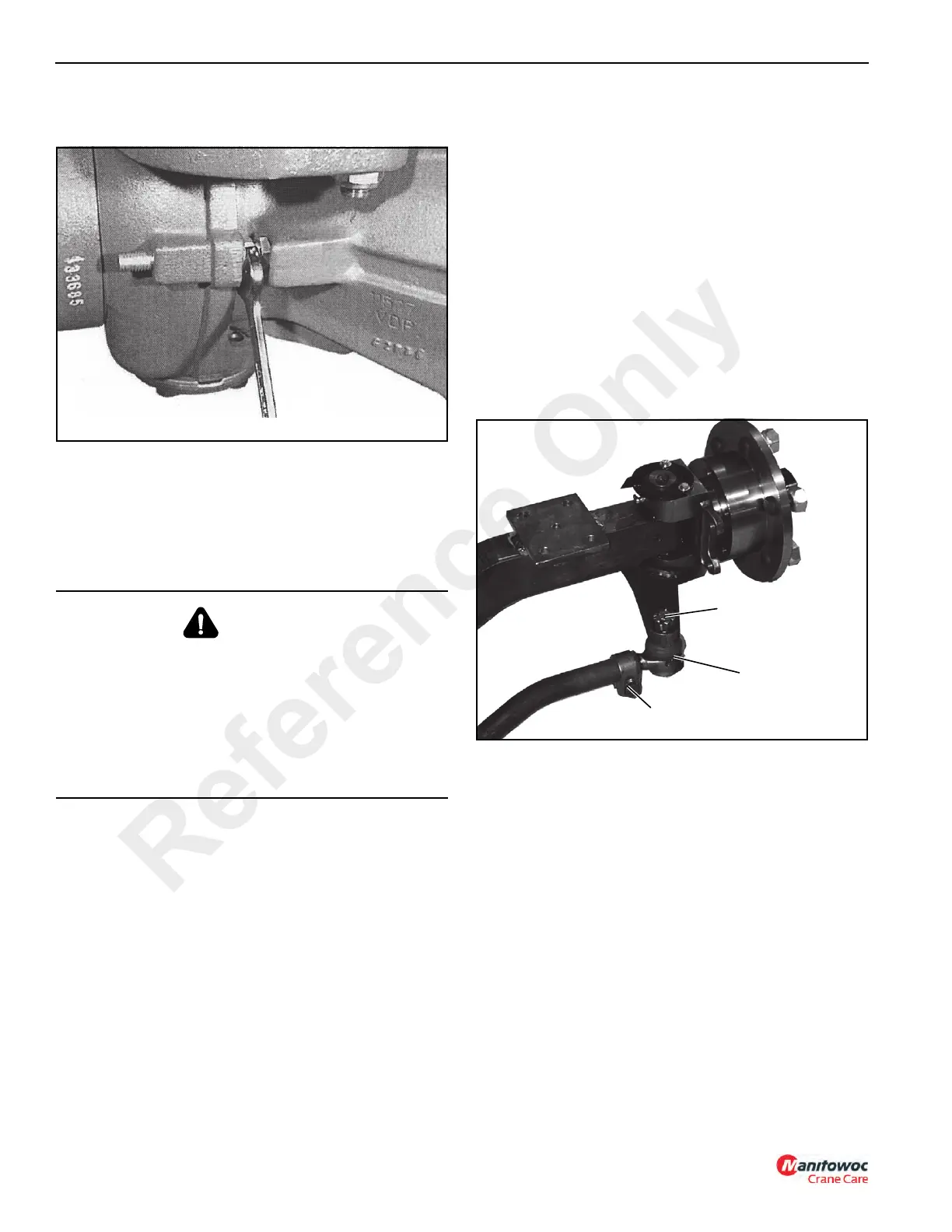

6. Loosen the lock nut on the steering angle screw

(Figure 8-13).

7. Screw the adjusting screw in or out until the correct

angle is obtained.

8. When the angle is adjusted correctly, steer completely in

the opposite direction and repeat steps 3 through 7.

Rear Steering Axle

Checking / Adjusting Toe-in

Checking with Axle on Machine

1. Place the wheels in the straight forward position.

2. Take measurements from the tire to the crane frame at

the four positions A, B, C and D indicated in Figure 8-3.

All four dimensions must be equal.

NOTE: If more than 6 mm (1/4 in) of adjustment is

necessary, make the adjustment on both ends of

the tie rod. Make sure both clamps on the tie rod

are tight when finished.

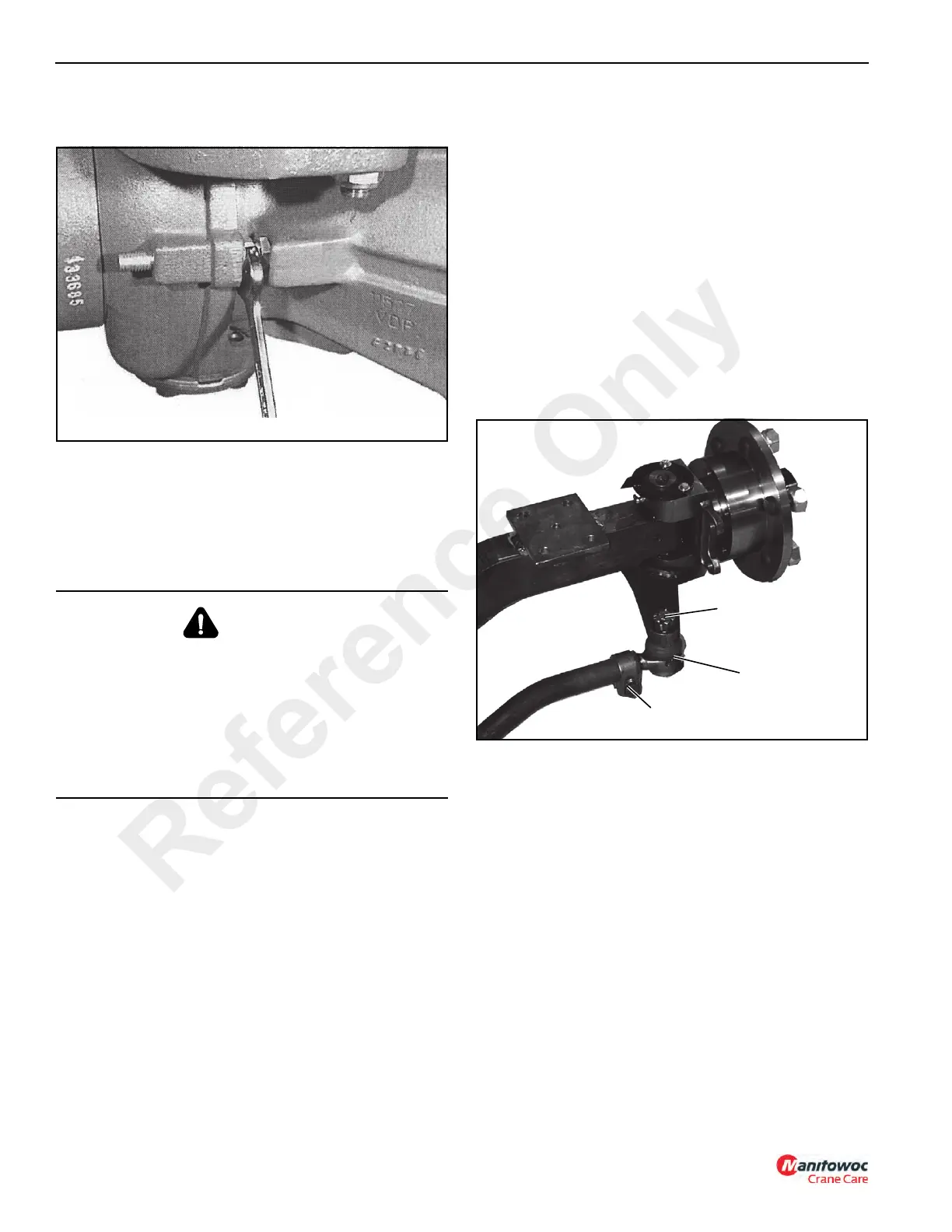

3. On one end of tie rod loosen the ball joint clamp

(Figure 8-14).

4. Remove the cotter pin from the castle nut. Remove the

castle nut.

5. Remove the ball joint from the steering knuckle.

6. Either screw the ball joint in or out to obtain equal

dimensions.

7. When the correct dimensions are obtained, tighten the

castle nut and install the cotter pin.

8. Tighten the ball joint clamp.

WARNING

A raised and badly supported machine can fall on you

causing severe injury or death. Position the machine on a

firm, level surface before raising one end. Ensure that the

other end is securely chocked. Do not rely solely on the

machine’s hydraulics or jacks to support the machine

when working under it.

Disconnect the battery cables while you’re under the

machine to prevent the engine from being started.

FIGURE 8-14

P0690

Cotter Pin and Nut

Ball Joint

Ball Joint Clamp

Reference Only

Loading...

Loading...