STRUCTURAL CD3340B/YB4411

11-22

Published 04/07/2015 Control # 569-00

the extra two tapped holes (Figure 11-34) and tighten

them evenly until the brake housing has come loose

from the mounting bracket. See Brake Section for repair

instructions.

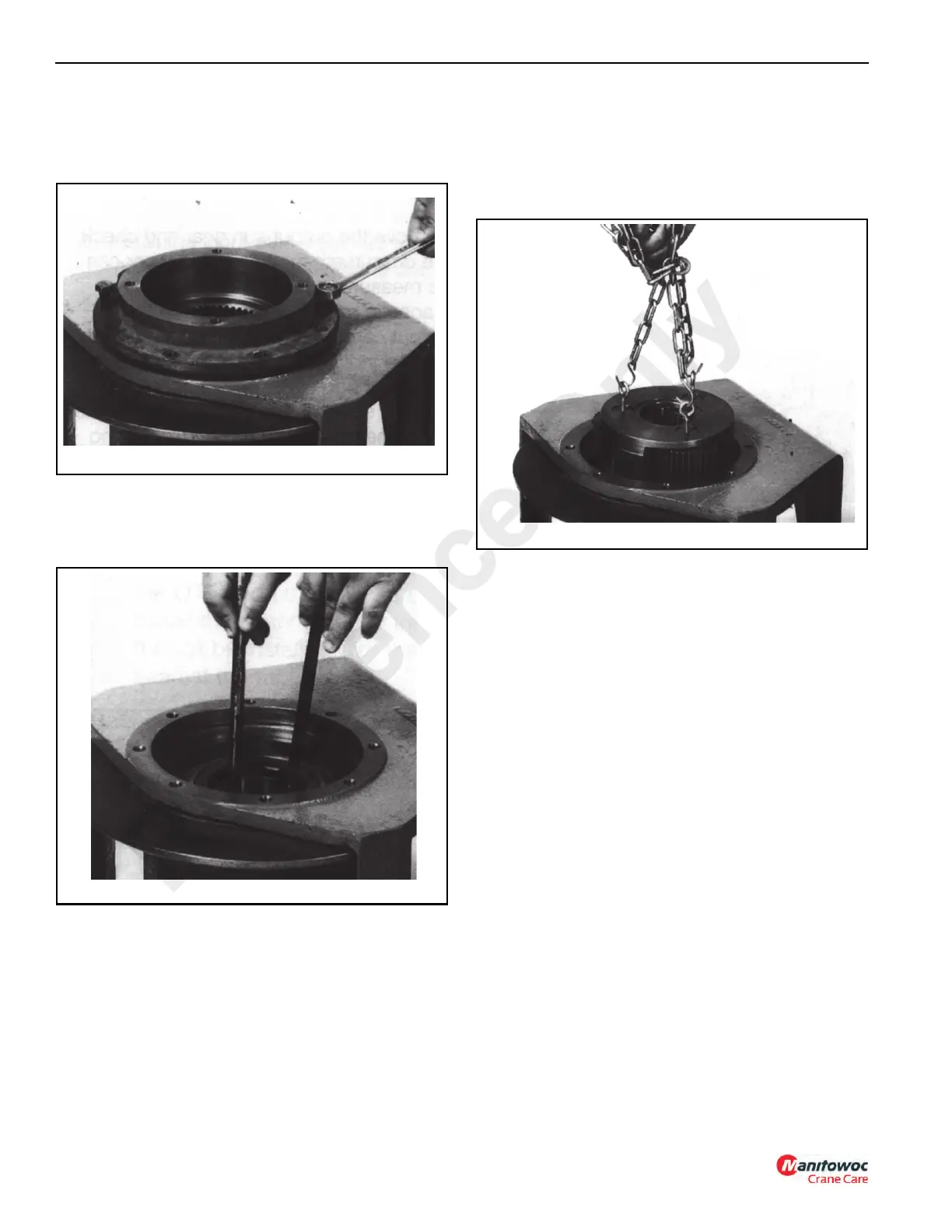

4. Using two crows foot pry bars (Figure 11-35), hook the

bearing carrier (11, Figure 11-33) from inside and pull it

out of the cable drum. Remove the bearing (5) and seal

(4) from the bearing carrier (11).

5. Remove the input sun gear (9, Figure 11-33) from the

input planet set (22).

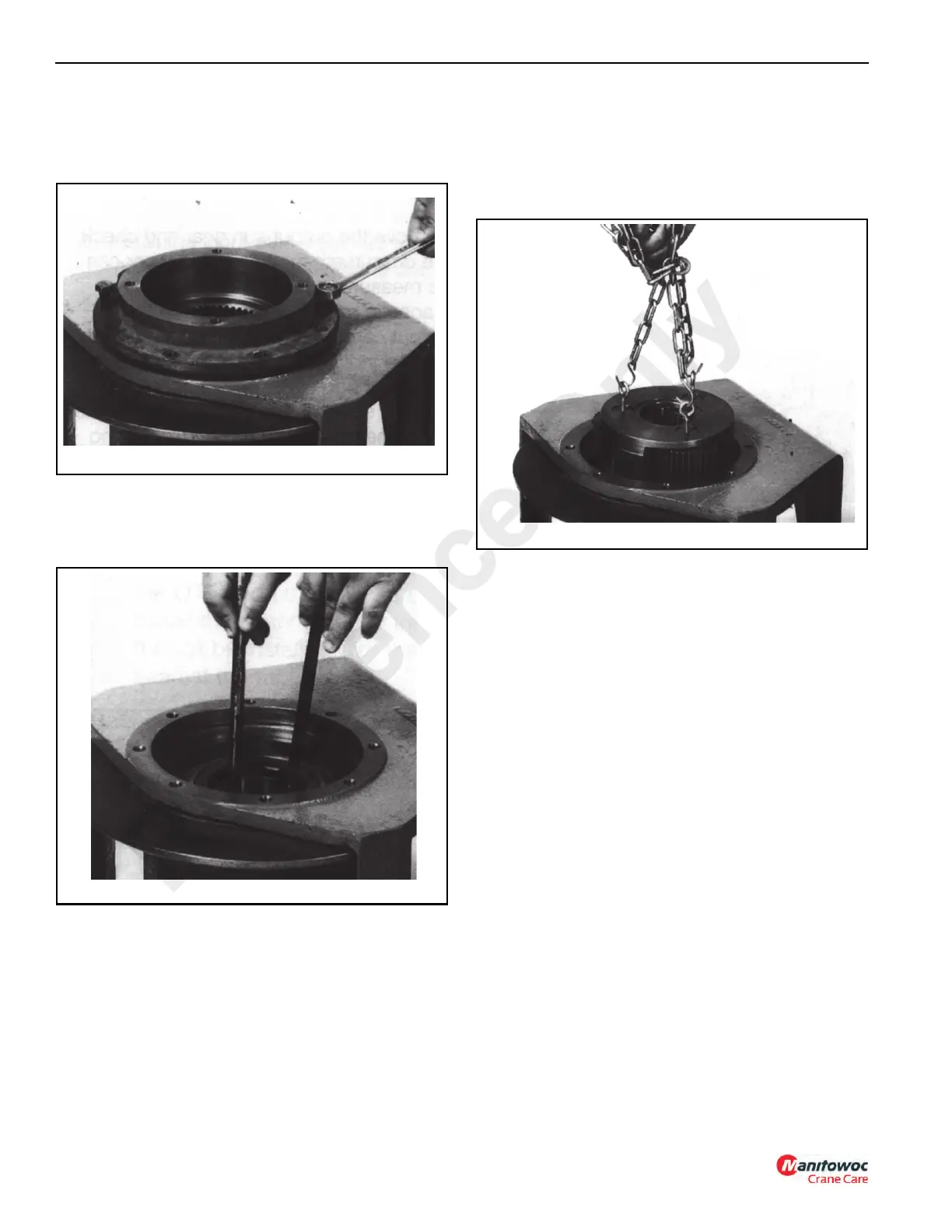

6. Install three 1/4 inch eyebolts (Figure 11-36) into the

three planet pins in the input planet set (22,

Figure 11-33). Use a piece of chain (Figure 11-36) to pull

the planet set from the drum. Inspect the planet set for

wear and repair as needed. See Planet Sets for repair

instructions.

7. Remove the output sun gear (16) and check drum (10)

teeth for wear. This wear can be measured as follows:

a. Place a magnetic base dial indicator on the output

carrier (8, Figure 11-33) and adjust the plunger of

the dial indicator approximately at the middle of one

of planet gear teeth.

b. Using a screwdriver or your finger, rotate the planet

gear back and forth, reading the movement on the

dial indicator. If the total movement is greater than

0.64 mm (0.025 in), then the drum should be

replaced.

Using the same procedure as in Step 6, remove the

output planet set (23, Figure 11-33) from the drum.

Inspect the planet set for wear and repair as necessary.

See Planet Sets for repair instructions.

8. Turn the hoist over onto the motor end and remove the

capscrews holding the output shaft (3, Figure 11-33) into

the mounting bracket. Reference mark for proper

assembly. Install two of the capscrews into the extra

threaded holes in the output shaft (Figure 11-37) and

evenly tighten them until the output shaft is free from the

mounting bracket.

Reference Only

Loading...

Loading...