Display

PRELIMINARY INFORMATION

NVIDIA Jetson Orin NX DG-10931-001_v0.1 | 49

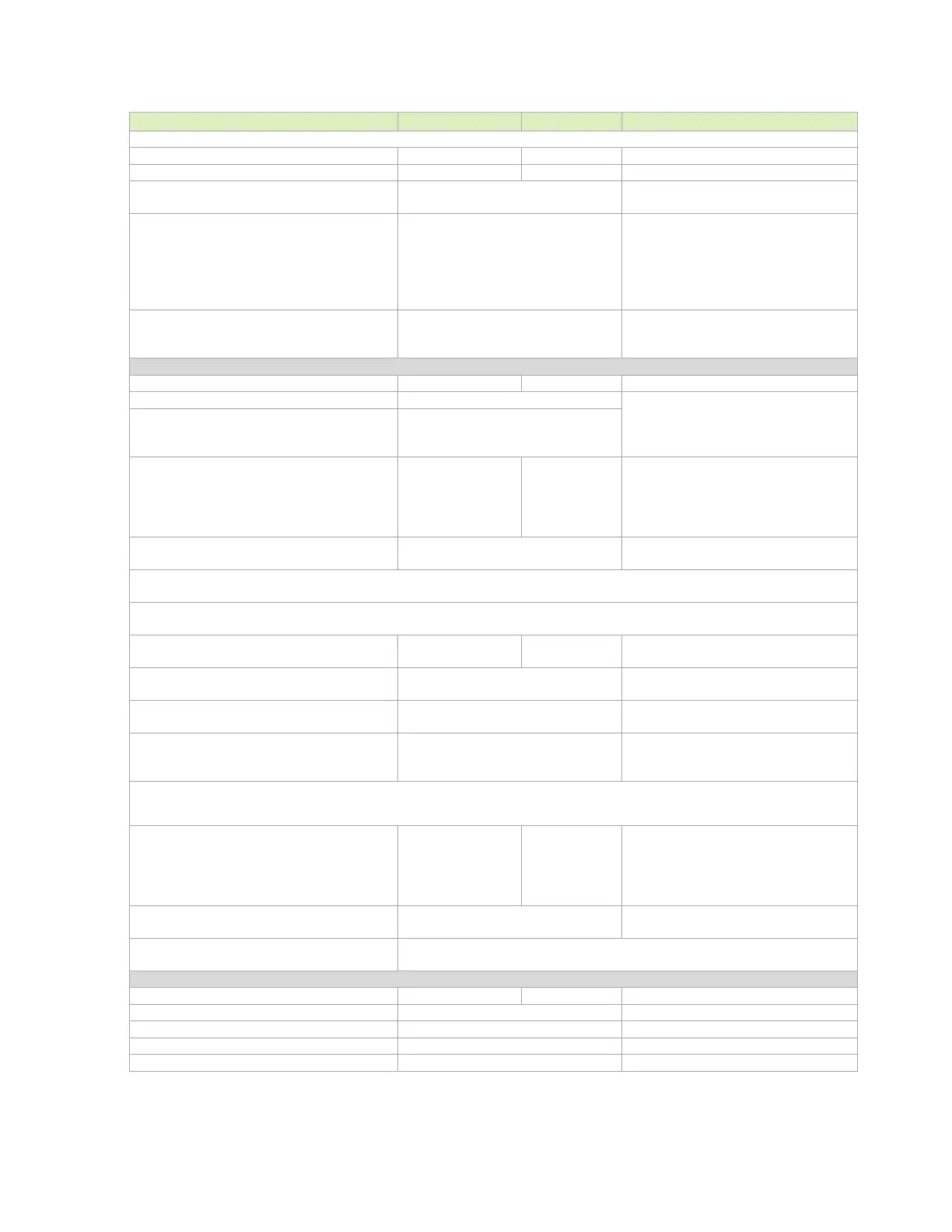

Max via distance from BGA

must be placed before pull-down

resistor

The distance between the AC cap and the

HDMI connector is not restricted.

PTH design

Micro-via design

Place cap on bottom layer if main route

above core

Place cap on top layer if main route

below core

GND (or PWR) void under/above the

cap is needed. Void size = SMT area +

1x dielectric height keepout distance

Pull-down Resistor (RPD), choke/FET

Must be placed after AC cap

Placement: See Figure 9-19

Same layer as AC cap. The FET and

choke can be placed on the opposite

PD

Max trace Rdc

Max trace length

600 or

1

≤20

Ω@100MHz

uH@DC-100MHz

mΩ

Can be choke or Trace. Recommended

option for HDMI2.0 HF1-9 improvement.

GND/PWR void under/above cap is

preferred

Common-mode Choke (Not recommended – only used if absolutely required for EMI issues)

See Chapter 17 for details on CMC if implemented.

ESD (On-chip protection diode can withstand 2kV HMM. External ESD is optional. Designs should include ESD footprint as a stuffing

option)

Max junction capacitance

(IO to GND)

e.g. Texas Instruments

TPD4E02B04DQAR

Pad right on the net instead of trace

stub

After pull-down resistor/CMC and

before RS

GND/PWR void under/above the cap is

needed. Void size = 1 mm x 2 mm for

Series Resistor (RS): Series resistor on P/N path for HDMI 2.0 but not required for HDMI 2.1 (Mandatory to meet HDMI 2.0

Compliance).

± 10%. 0ohm is acceptable if the design

passes the HDMI2.0 HF1-9 test.

Otherwise, adjust the R

S value to ensure

the HDMI2.0 tests pass: Eye diagram,

Vlow test and HF1-9 TDR test

After all components and before HDMI

connector

GND/PWR void under/above the R

S

device is needed. Void size = SMT area + 1x

dielectric height keepout distance.

Trace at Component Region

At component region (Microstrip)

Trace entering the SMT pad

Loading...

Loading...