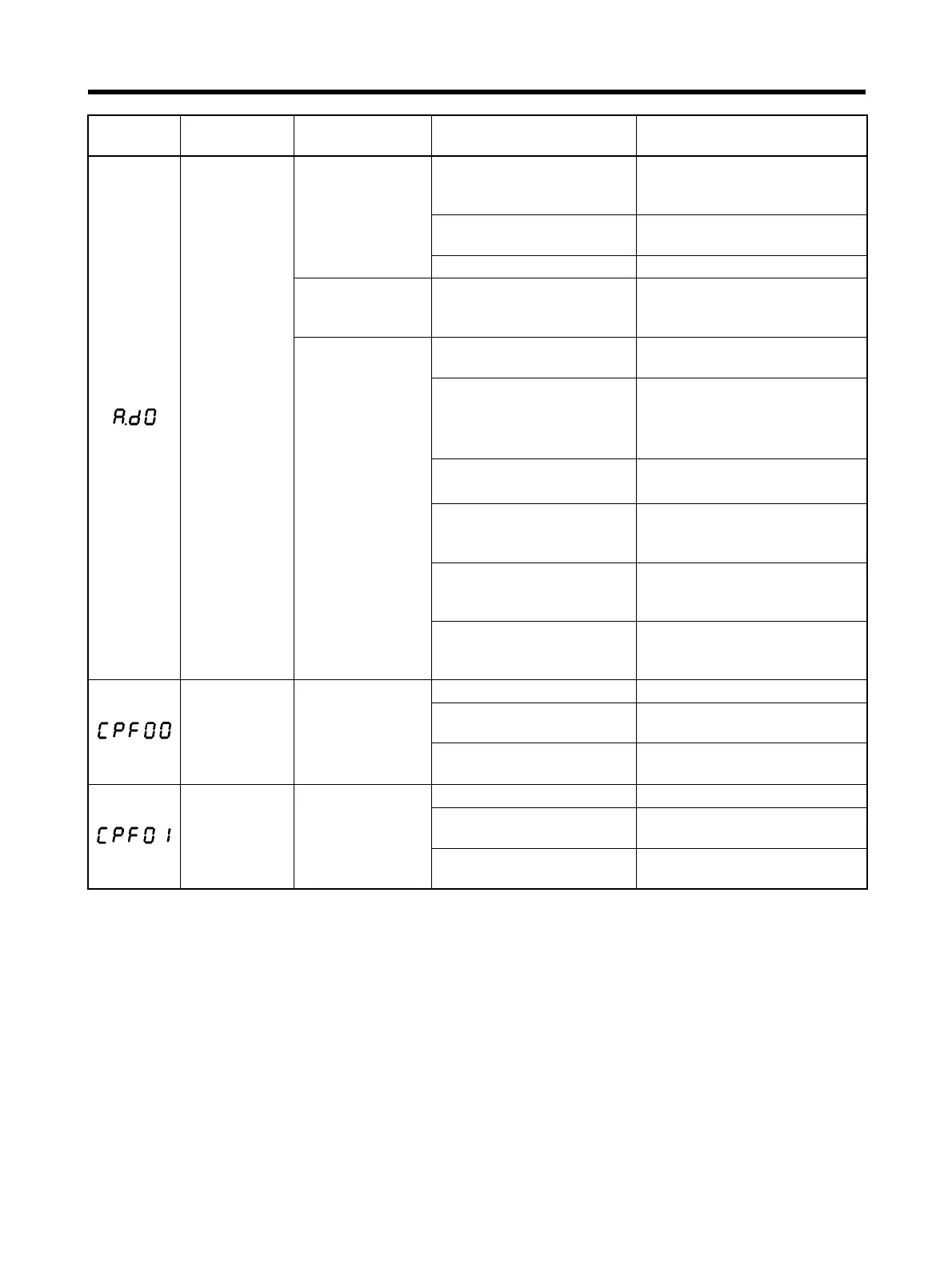

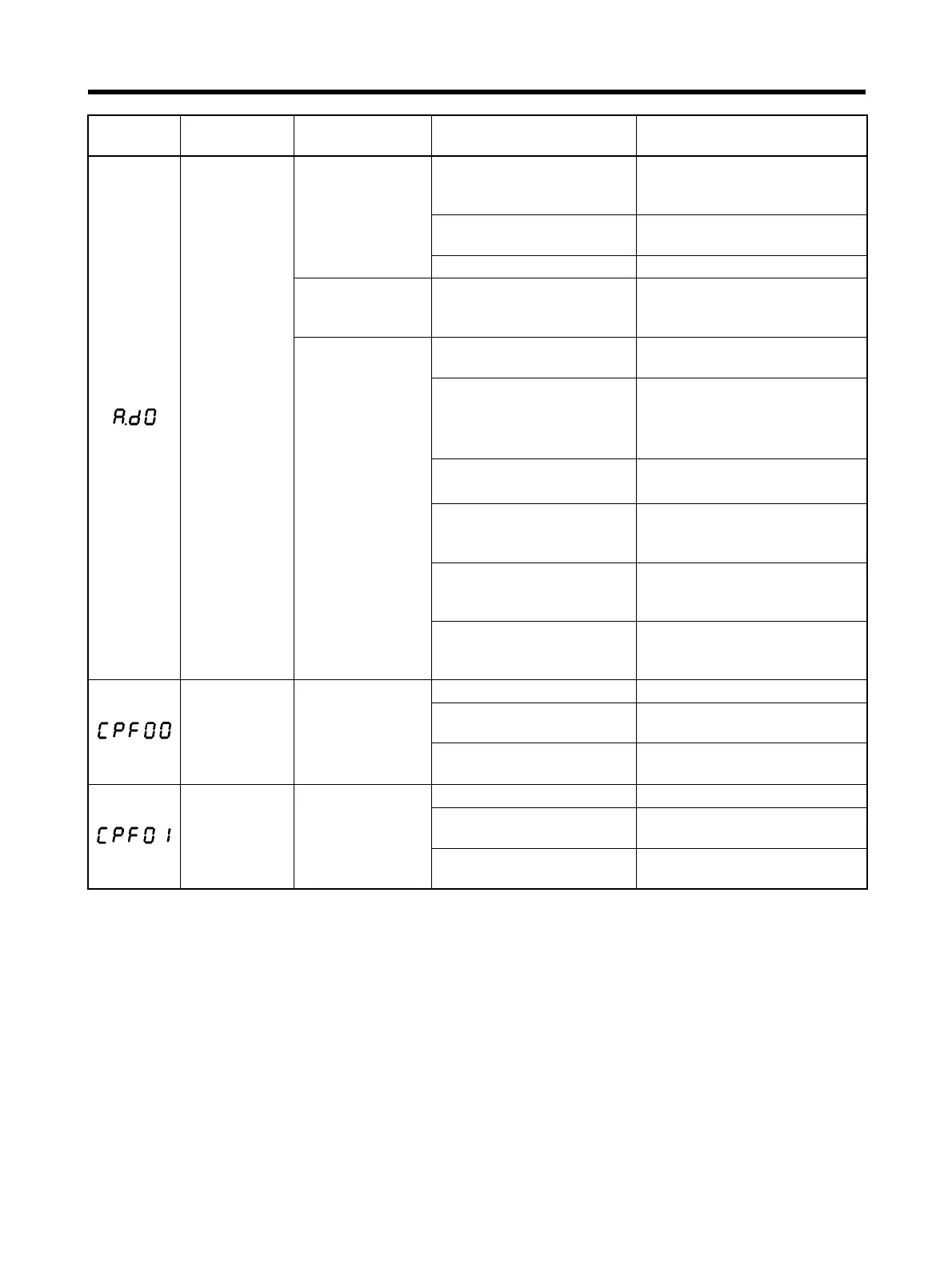

Chapter 5

5-11

Troubleshooting

Deviation

counter over-

flow

Servomotor will

not rotate even

when command

pulses are input.

Servomotor power or

encoder line is wired incor-

rectly.

Rewire correctly.

Locked mechanically Repair if the Servomotor shaft

is locked

Control panel error Replace the Servo Driver.

Occurs when

rotating at high

speed

Servomotor power or

encoder line is miswired.

Rewire correctly.

Occurs when long

command pulses

are sent

Gain adjustment is insuffi-

cient.

Adjust the gain.

Acceleration and decelera-

tion is too violent.

Lengthen acceleration and

deceleration time.

Use position command filter

(Pn207.0, Pn204, and Pn208).

Load is too large. Lighten the load.

Reselect the Servomotor.

Pn505 (deviation counter

overflow level) setting is too

large.

Reset the parameter correctly.

Resolution setting switch

(switches 4 and 5) setting is

too low.

Reset the switches correctly.

Pn202 and Pn203 (elec-

tronic gear ratio) setting is

too large.

Reset the parameters correctly.

Parameter

Unit transmis-

sion error 1

Occurs when

power supply is

turned ON.

Faulty Connector contact. Plug the Connector in securely.

Internal element malfunc-

tion.

Turn OFF the power supply,

then ON again.

Internal element is faulty. Replace the Servo Driver.

Replace the Parameter Unit.

Parameter

Unit transmis-

sion error 2

Occurs when

Parameter Unit is

in use.

Faulty Connector contact. Plug the Connector in securely.

Internal element malfunc-

tion

Turn OFF the power supply,

then ON again.

Internal element is faulty

Replace the Servo Driver.

Replace the Parameter Unit.

Display Error Status when

error occurs

Cause of error Countermeasures

Loading...

Loading...