354

Cleaning and Inspection Section 11-5

11-5 Cleaning and Inspection

Use the cleaning and inspection methods described here for daily mainte-

nance of the devices.

11-5-1 Cleaning

To keep the Serial Communications Board in optimum condition, regularly

clean the Board or Unit, as follows:

• Wipe the surface of the Board or Unit daily with a soft, dry cloth.

• If any dirt cannot be removed with a dry cloth, moisten the cloth with a

mild detergent diluted to 2%, and squeeze out any excess moisture

before wiping the Board or Unit.

• Do not adhere materials, such as gum, vinyl, or tape to the Board or Unit

for long periods of time. Doing so may cause scratches on the device.

Remove any adhered materials when cleaning the Board or Unit.

Note Never use benzene, paint thinner, or other volatile solvents, and do not use

chemically treated cloths.

11-5-2 Inspection

To keep the Board or Unit in optimum condition, regular inspections must be

performed. Normally, inspect the devices once every six months or every year.

Inspect the devices at more regular intervals when they are being used in

environments subject to high temperatures, high humidity, or high dust levels.

Materials for Inspection Prepare the following materials before performing any inspections.

Materials Required Daily

For daily inspection, a Phillips screwdriver, flat-blade screwdriver, tester (or

digital voltmeter), industrial strength alcohol, and all-cotton cloth are required.

Materials Required Occasionally

For some inspections, a synchroscope, a pen oscilloscope, a temperature

gage, and a hydroscope will be required.

Inspection Items Inspect the following items to check whether the Board or Unit is operating

within the specified criterion. If the Board or Unit is not within the criterion,

improve the ambient operating environment and readjust the device.

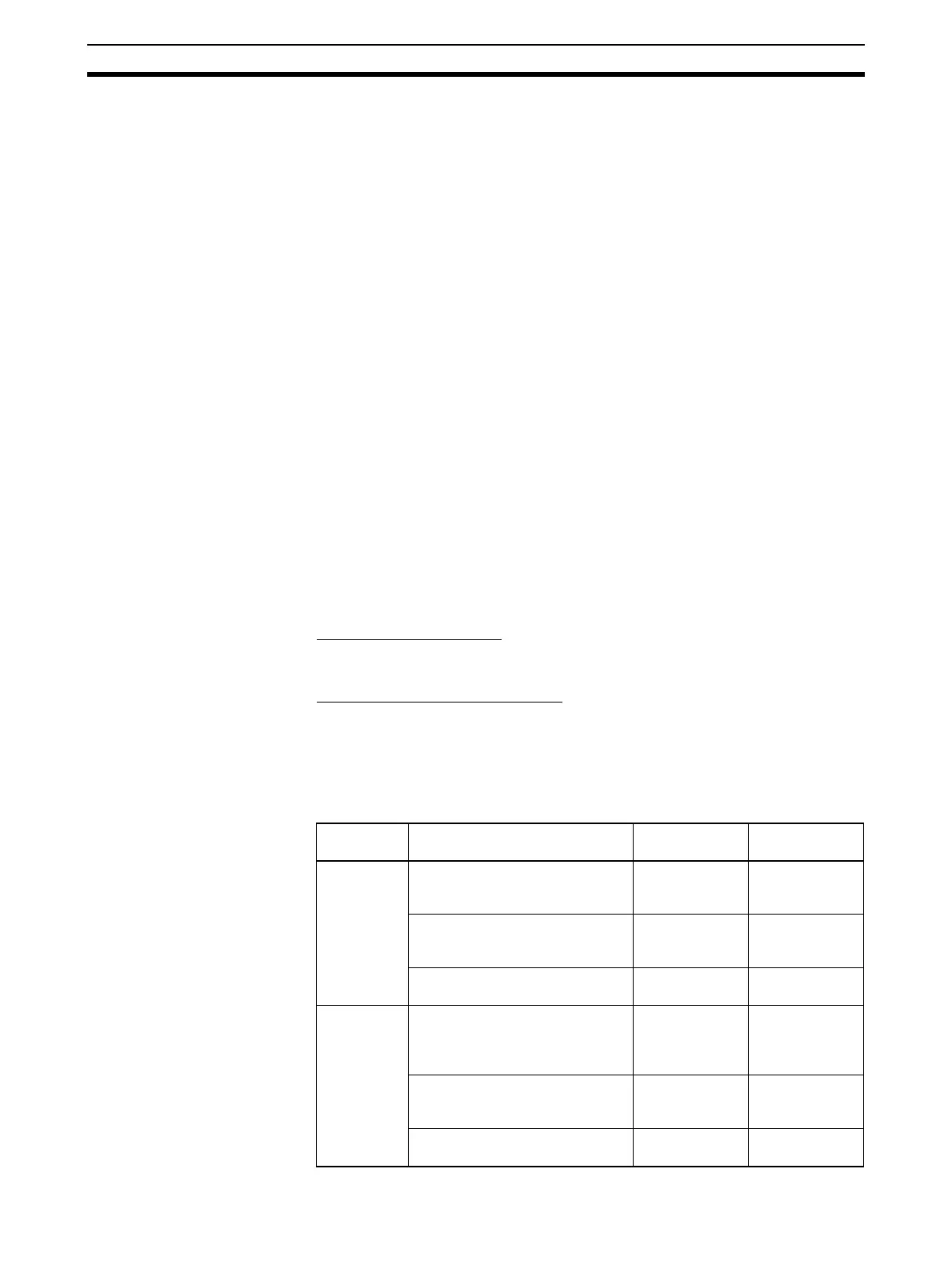

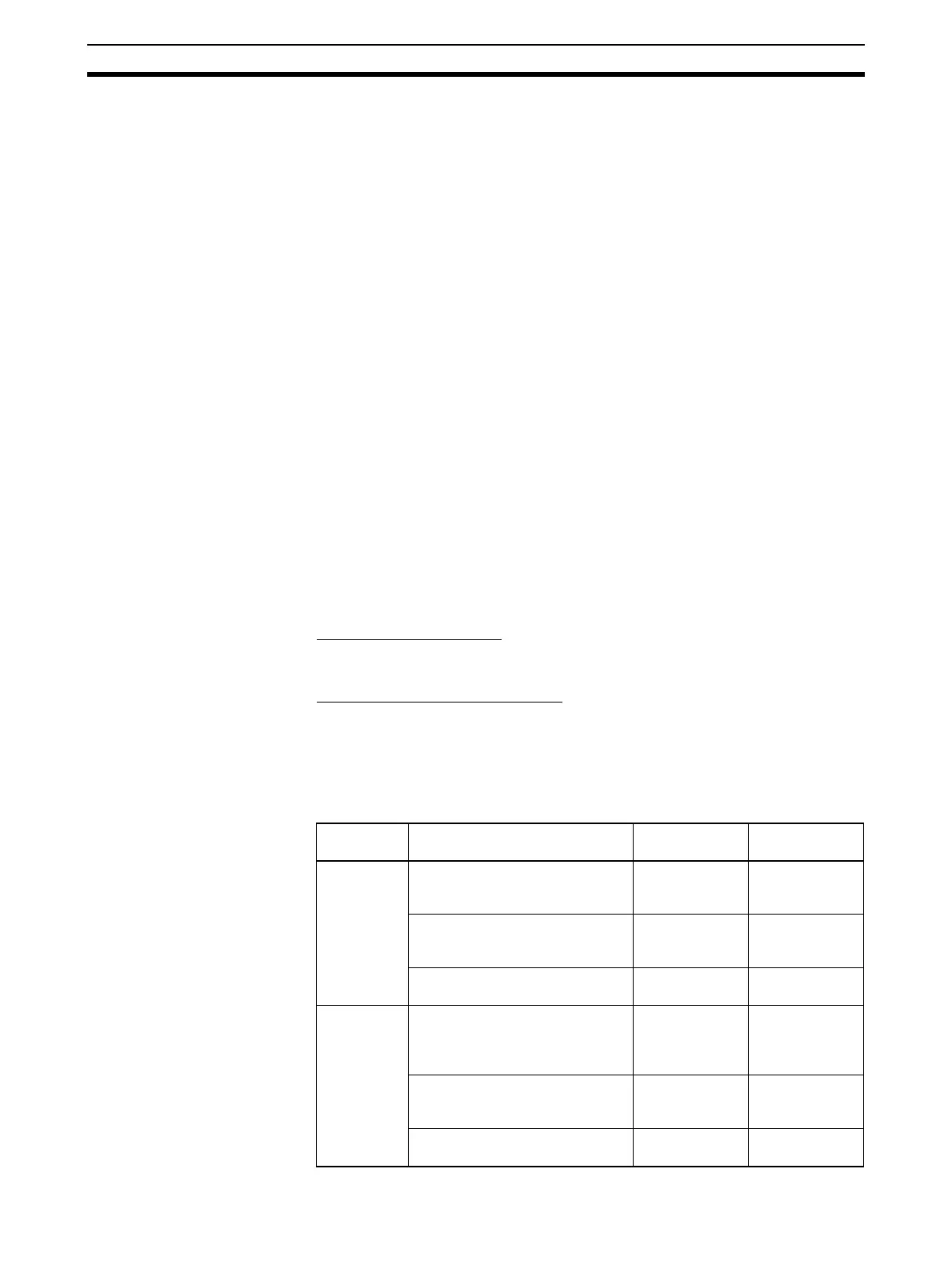

Item Details Criterion Inspection

materials

Operating

environment

Check the ambient temperature

and the temperature of the control

panel.

0 to 55°C Temperature

gage

Check the ambient humidify and

the humidity of the control panel.

10% to 90% RH

(no condensa-

tion or icing)

Hydroscope

Check for accumulated dust. No dust Visual

inspection

Installation Check that the Board or Unit is

mounted securely.

Board or Unit

must be

mounted

securely.

---

Check for loose screws on the

communications cables.

Screws must be

securely tight-

ened.

Phillips screw-

driver

Check for damaged

communications cables.

Cables should

be fully intact.

Visual

inspection

Loading...

Loading...