Name Torque in Nm

Oil vent pipe fixing 3 ÷ 4

Minimum oil pressure sensor 12 ÷ 14

Fairlead bracket fixing 3 ÷ 4

Head/Cylinder/Crankcase fixing 10 ÷ 12

Revolution timing sensor fixing screw 3 ÷ 4

Coolant temperature sensor 10 ÷ 12

Pressure reducer counterweight retainer 7 ÷ 8.5

Counter shaft gear fixing on driving shaft (#) 10 ÷ 12

Thermostat cover 1,5 ÷ 2

Start-up rim counter shaft plate fixing 3 ÷ 4

Injector support fixing (#) 3 ÷ 4

Head lubrication control jet 5 - 7

(°)Lubricate parts before fitting.

(^) Apply LOCTITE for surfaces type 510.

(#) Apply thread-holding LOCTITE medium type 242.

(§) 1st locking: 20 N·m crossed, locking at torque 38 - 42 N·m crossed, crossed loosening.

(*) 2nd tightening: 20 N·m crossed, locking at torque 38 - 42 N·m crossed.

N.B.

LUBRICATE THE THREADS.

NOTICE OF TECHNICAL SERVICING

For correct tightening, the expansion tank cap locking torque has been standardised to 2.5 Nm

Please take note that we have normalized to 17 - 20 Nm the temperature sensor locking torque, in order

to guarantee a correct locking

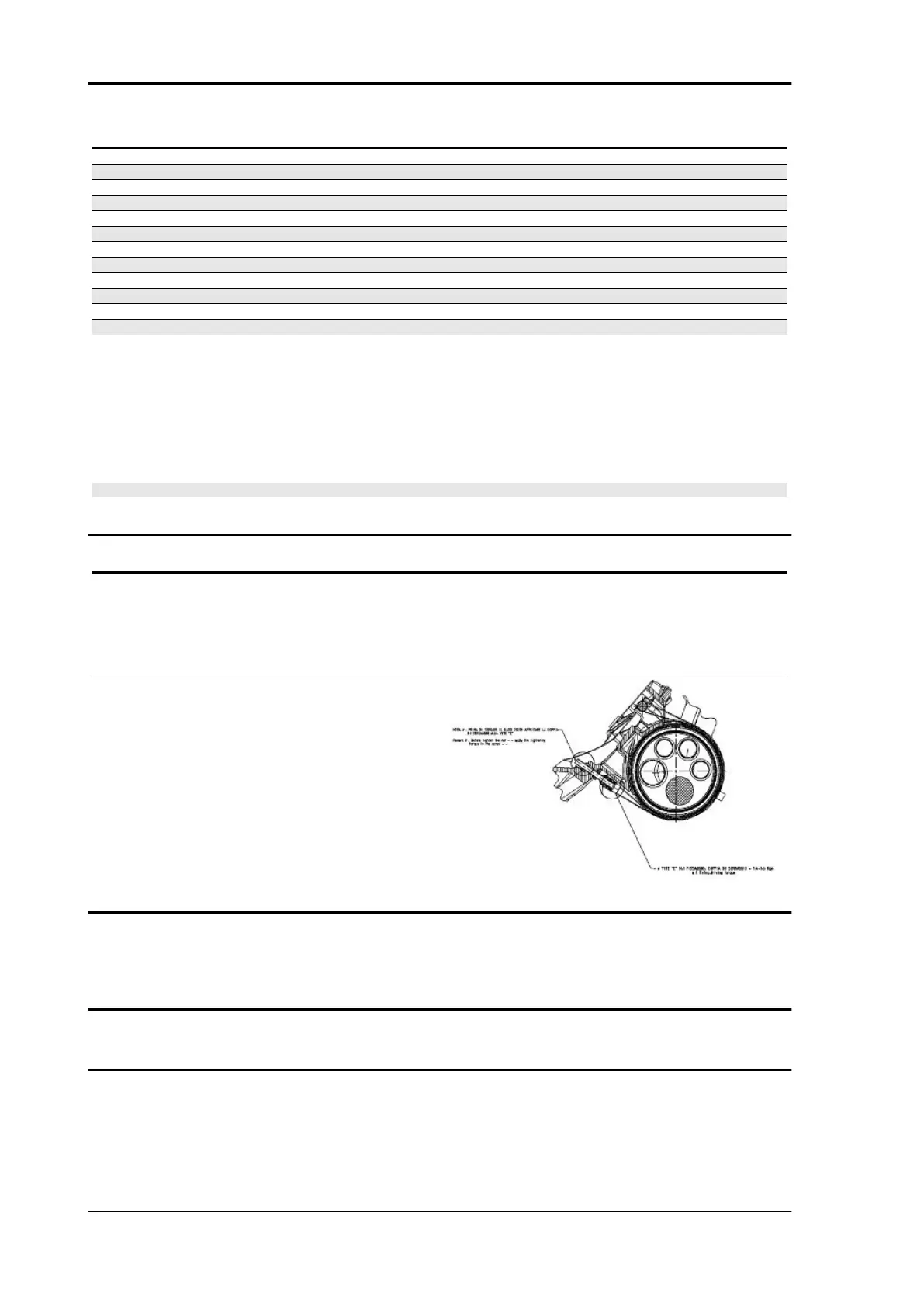

This is to inform you that the tightening torque for

screws with dwg. no. 842502 has been increased

from 8-10 Nm to 14-16 Nm, to prevent the exhaust

pipe from coming loose.

Overhaul data

This section provides the main information for scooter servicing.

Assembly clearances

Characteristics X9 Evolution 500

CHAR - 14