- Calculate the piston pin coupling clearance.

N.B.

THE PIN HOUSINGS HAVE 2 LUBRICATION CHANNELS.

FOR THIS REASON, MEASUREMENT MUST BE MADE AC-

CORDING TO THE PISTON AXIS.

Characteristic

Standard clearance:

0.001 ÷ 0.010 mm

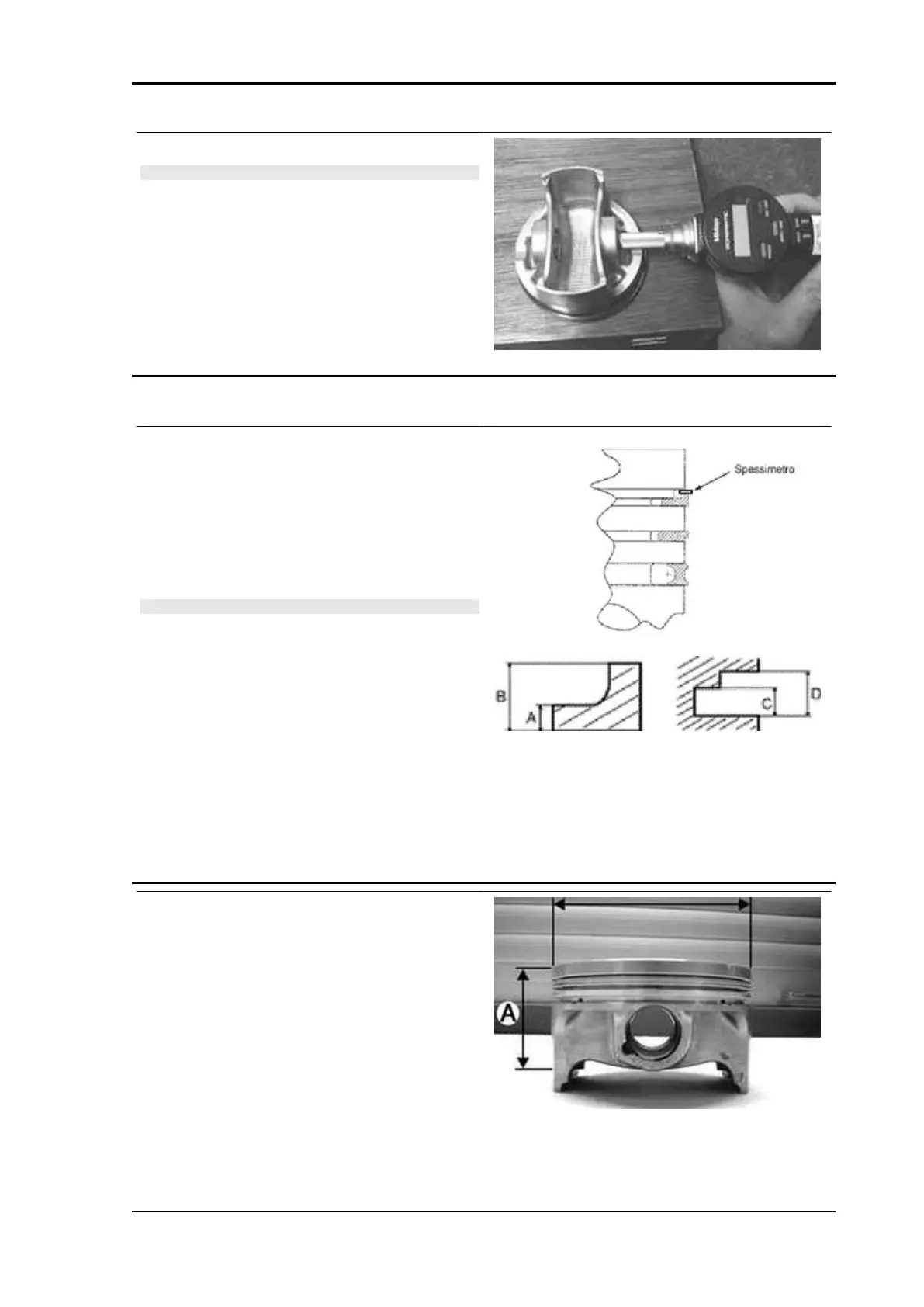

Inspecting the piston

- Carefully clean the seal housings.

- Measure the coupling clearance between the

seal rings and the grooves using suitable sensors,

as shown in the diagram.

- If the clearance is greater than that indicated in

the table, replace the piston.

N.B.

MEASURE THE CLEARANCE BY INSERTING THE BLADE

OF THE FEELER THICKNESS GAUGE FROM THE SECOND

SEAL SIDE.

Fitting clearance (Cylindrin/Pison)

Standard coupling clearance A 0.9 - 0.005 -0.030mm B 1.5 - 0.005 -0.03mm Maximum permissible

clearance after use C 0.9 + 0.03 +0.01mm D 2 + 0.05 +0.02mm Standard coupling clearance </>

1.2 - 0.005 mm </> </> Maximum permissible clearance after use </> 1.25 + 0.03 mm </> </>

Standard coupling clearance </> 2.5 - 0.005 mm </> </> Maximum permissible clearance after

use </> 2.5 + 0.03 mm </> </>

- Measure the outside diameter of the piston, per-

pendicular to the gudgeon pin axis.

- Take the measurement in the position shown in

the figure.

Characteristic

A =

43.2 mm

Piston diameter:

92 mm

X9 Evolution 500 Engine

ENG - 147

Loading...

Loading...