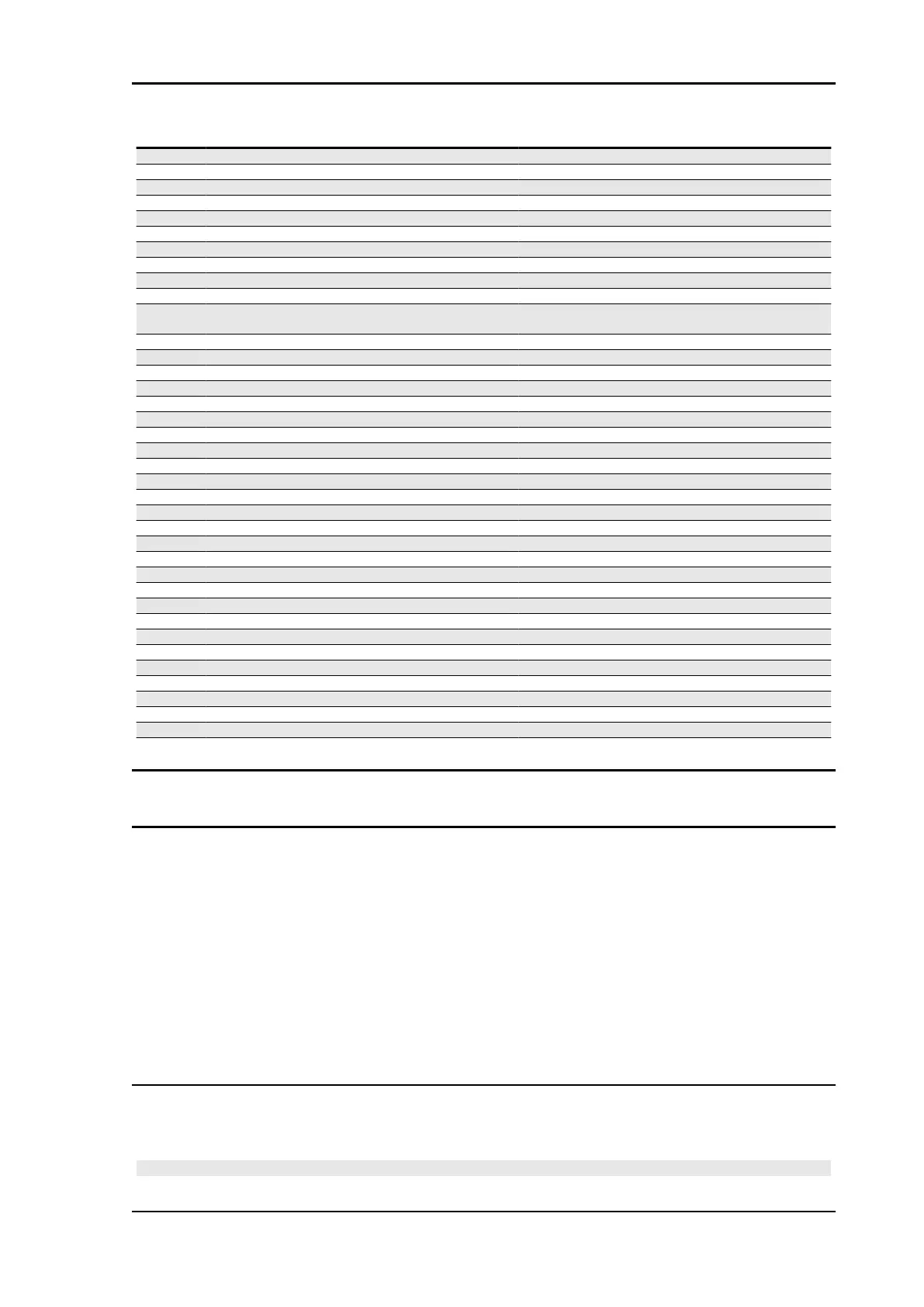

Specification Desc./Quantity

13 Diode 2 A

14 Key switch contacts

15 Engine warning indicator

16 Engine not enable indicator

17 Low fuel warning light

18 High-beam warning light

19 Wheel RPM sensor

20 Outside temperature sensor

21 Digital instrument unit

22 Fuel level sender

23 Control unit power supply remote control switch (engine

stop)

24 Electronic control unit components remote control switch

25 Saddle opener receiver

26 Pump remote control switches

27 Side stand pump motor

28 Stuck relay indicator

29 Side stand out enable button

30 Side stand in enable button

31 Electro-hydraulic side stand actuation button

32 Side stand control unit

33 Tilting sensor

34 Air temperature sensor

35 Engine rpm sensor

36 Double wire screened cable

37 Fuel injector

38 Idle adjustment motor

39 Fuel pump

40 Engine temperature sensor

41 Diagnostics socket connector

42 Throttle potentiometer

43 Start-up/injection electronic control unit

44 Fuse no. 5 15A

45 Fuse no. 6 10A

46 Fuse no. 14 70A

47 Fuse no. 2 10A

48 Fuse no. 1 5A

49 Fuse no. 4 5 A

50 Fuse no. 12 7,5 A

Checks and inspections

Battery recharge circuit

The recharge system is provided with a three phase alternator with permanent flywheel.

The alternator is directly connected to the voltage regulator.

This, in its turn, is connected directly to the ground and the battery positive terminal passing through

the 30A protective fuse.

This system therefore requires no connection to the key switch.

The three- phase generator provides good recharge power and at low revs, a good compromise is

achieved between generated power and idle stability.

Stator check

Stator winding check-up

WARNING

THIS CHECK-UP CAN BE MADE WITH THE STATOR PROPERLY INSTALLED.

X9 Evolution 500 Electrical system

ELE SYS - 61

Loading...

Loading...