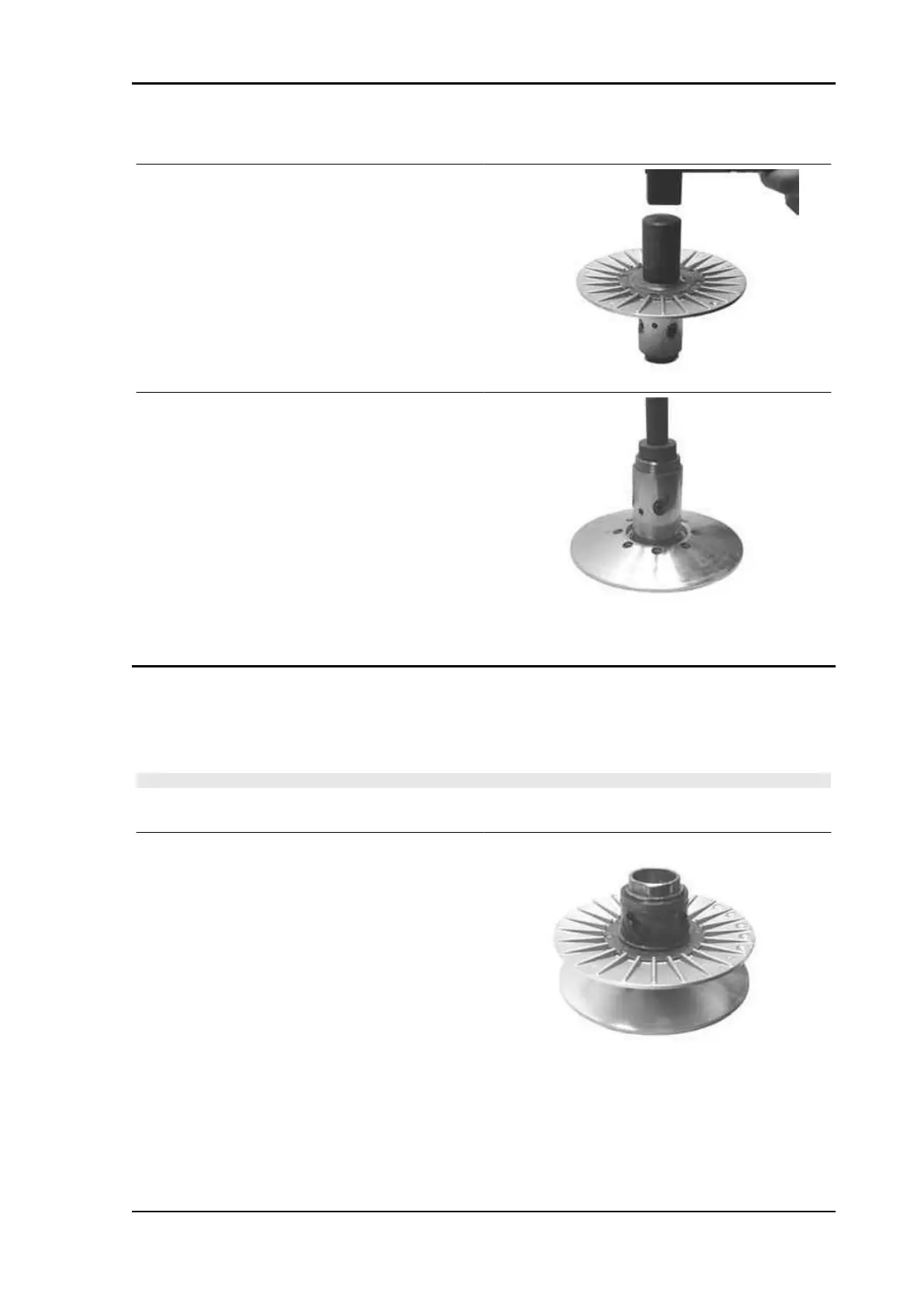

If you are working on the driven pulley unit fully assembled, use the special tool.

Specific tooling

020478Y Punch for driven pulley roller casing

001467Y002 Driver for OD 73 mm bearing

- Install a new ball bearing using the special tool.

Specific tooling

020376Y Adaptor handle

020477Y Adaptor 37 mm

020363Y 20 mm guide

- Insert the Seeger lock ring.

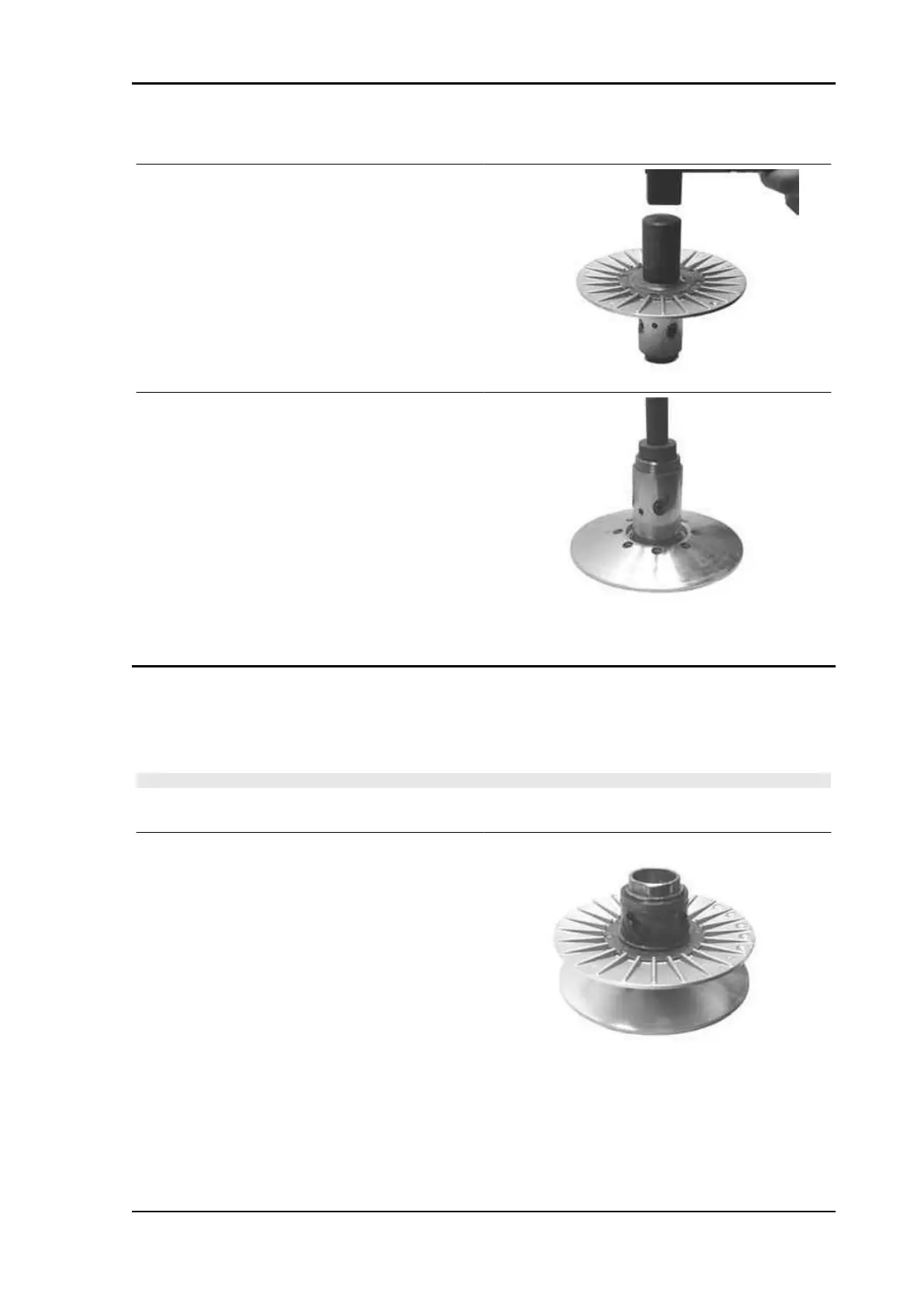

Refitting the driven pulley

- Insert the new oil guards

- Insert the new O-rings

N.B.

O-RINGS ARE OF TWO SIZES. THE LARGE ONE IS INSTALLED ON THE MACHINING END RA-

DIUS, AT THE BASE OF THE HALF-PULLEY.

- Install the half-pulley on the bushing being careful

not to damage the top sealing ring during the in-

troduction.

- Make sure the pins and collar are not worn, re-

assemble the pins and collar.

- Using a bent beak greaser, lubricate the driven pulley unit with about 10 gr. of grease, this operation

should be carried out through one of the two holes into the bushing to obtain the exit of the grease from

the opposite hole. This operation is necessary to avoid the presence of grease beyond the O-rings.

Recommended products

AGIP GREASE SM 2 Grease for the tone wheel revolving ring

X9 Evolution 500 Engine

ENG - 97

Loading...

Loading...