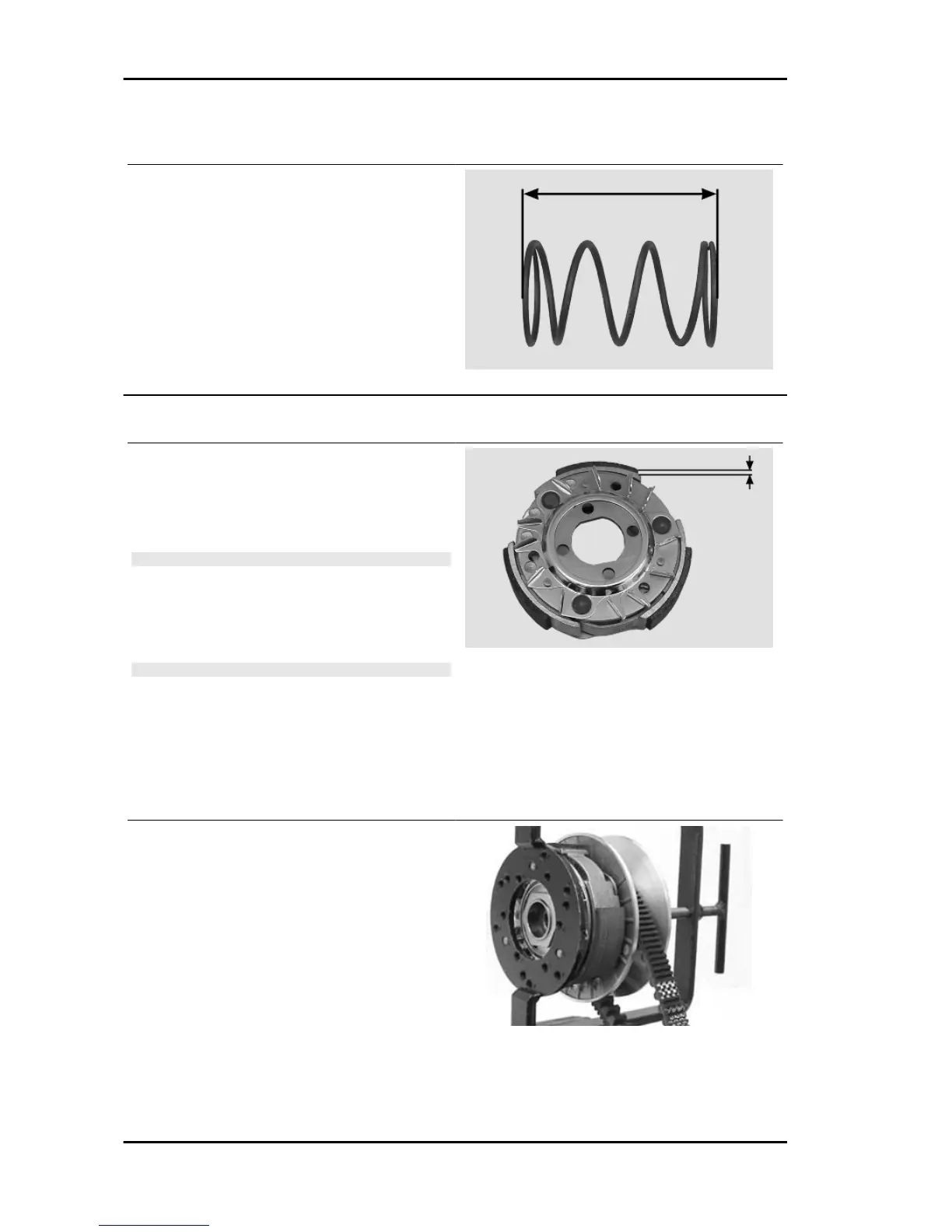

Inspecting the clutch spring

- Measure the unloaded length of the spring of the

movable driven half-pulley.

Characteristic

Standard length:

106 mm

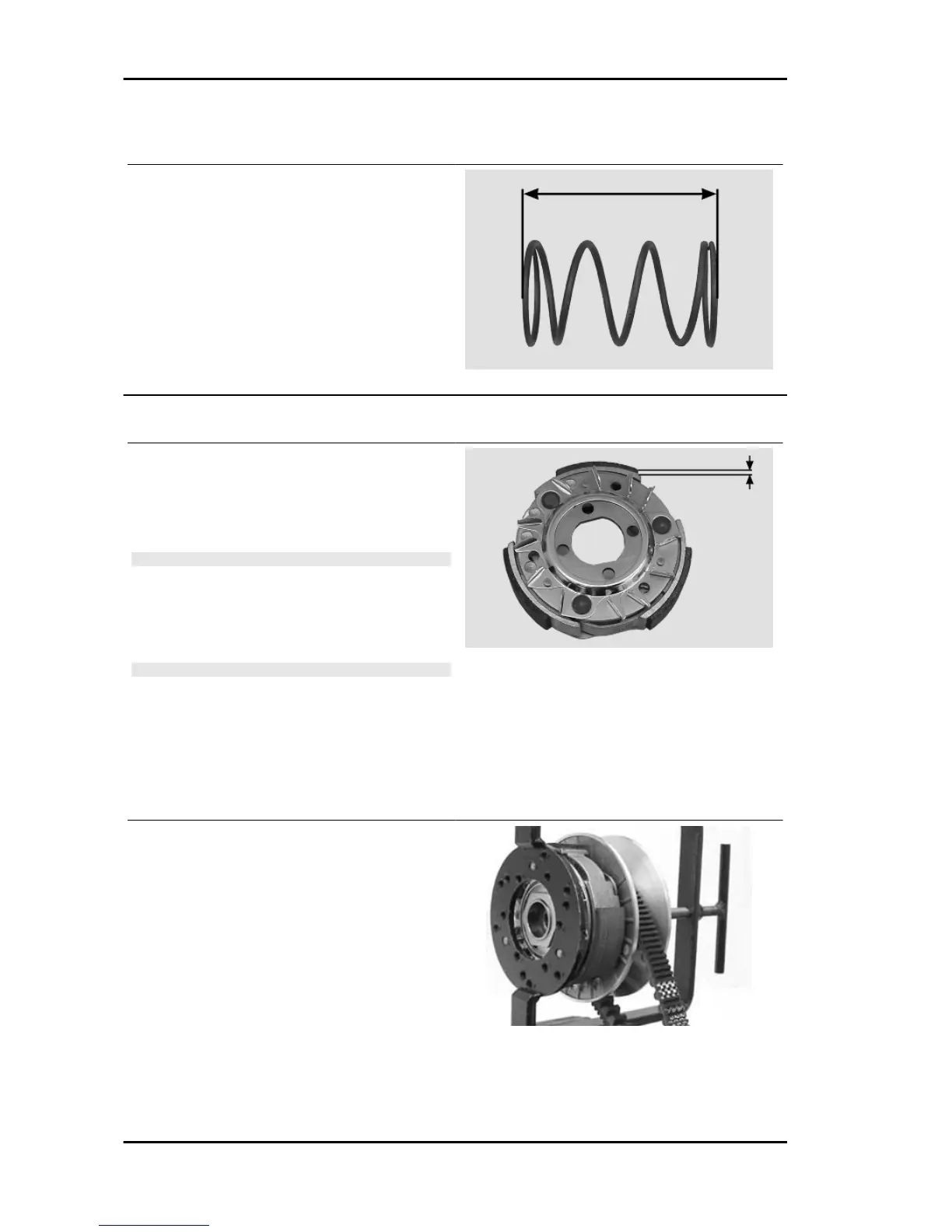

Refitting the clutch

- Check the thickness of the clutch mass friction

material.

-The masses must not show traces of lubricants;

otherwise, check the driven pulley unit.

N.B.

UPON RUNNING-IN, THE MASSES MUST EX-

HIBIT A CENTRAL CONTACT SURFACE AND

MUST NOT BE DIFFERENT FROM ONE AN-

OTHER. VARIOUS CONDITIONS CAN CAUSE

THE CLUTCH TO TEAR.

CAUTION

DO NOT OPEN THE MASSES USING TOOLS

SO AS TO PREVENT A VARIATION IN THE RE-

TURN SPRING LOAD.

Characteristic

Minimum thickness permitted:

1 mm

- Support the driven pulley spring compressor ap-

propriate tool with the control screw in vertical axis.

- Arrange the tool with the medium length pins

screwed in position "C" on the inside.

- Introduce the adapter ring 11 with the chamfering

facing upwards.

- Insert the clutch on the adapter ring.

- Lubricate the end of the spring that abuts against

the servo-system closing collar.

- Insert the spring with its plastic holder in contact

with the clutch.

Engine Fly 125 - 150 4T

ENG - 92

Loading...

Loading...