TO AVOID SCORING THE CONTACT SURFACE, DO NOT KEEP ROTATING THE VALVE WHEN

NO LAPPING COMPOUND IS LEFT. CAREFULLY WASH THE CYLINDER HEAD AND THE

VALVES WITH A SUITABLE PRODUCT FOR THE TYPE OF LAPPING COMPOUND BEING USED.

CAUTION

DO NOT REVERSE THE FITTING POSITIONS OF THE VALVES (RIGHT - LEFT).

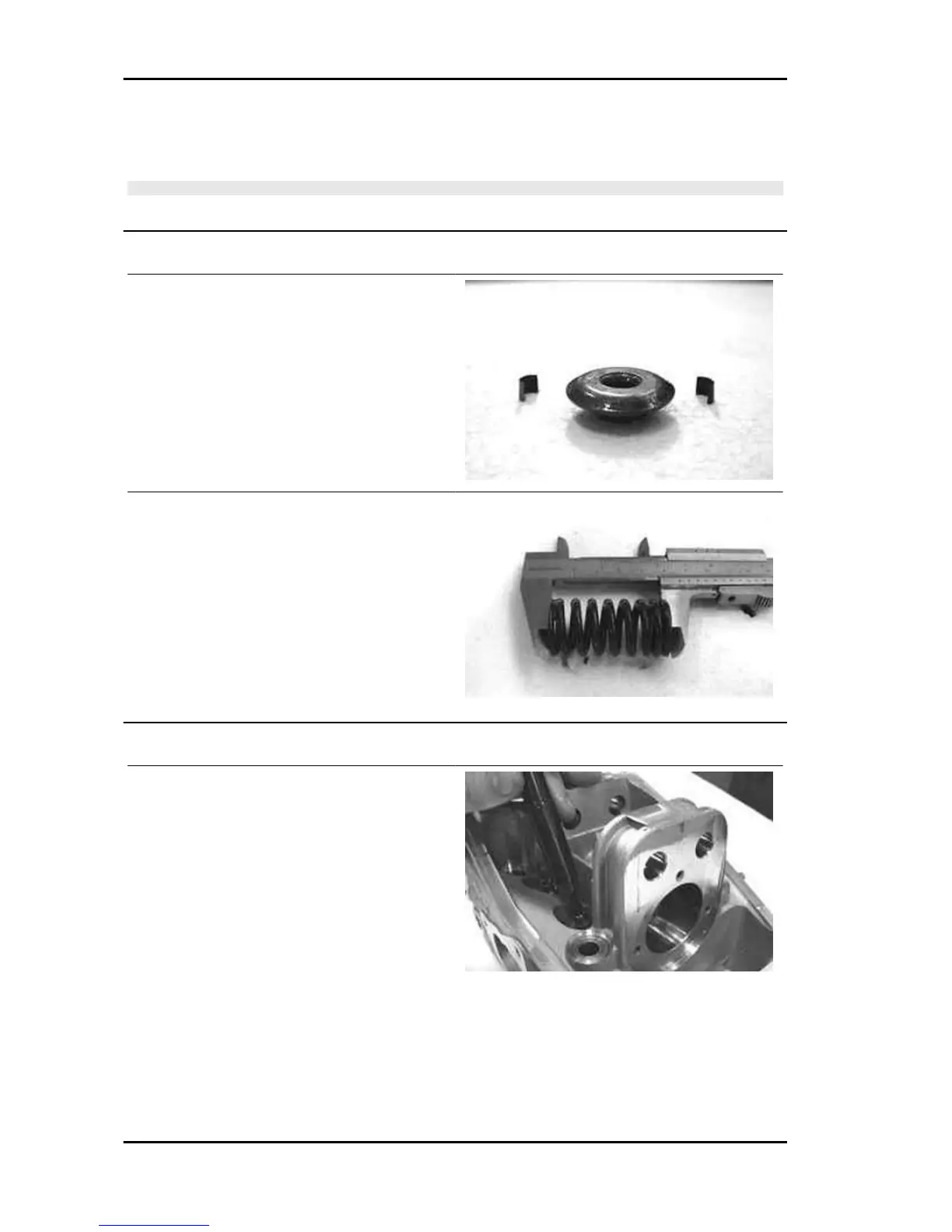

Inspecting the springs and half-cones

- Check that the upper and lower supporting spring

washers, the cotters and the oil seal show exhibit

no signs of abnormal wear. Replace a component

when worn.

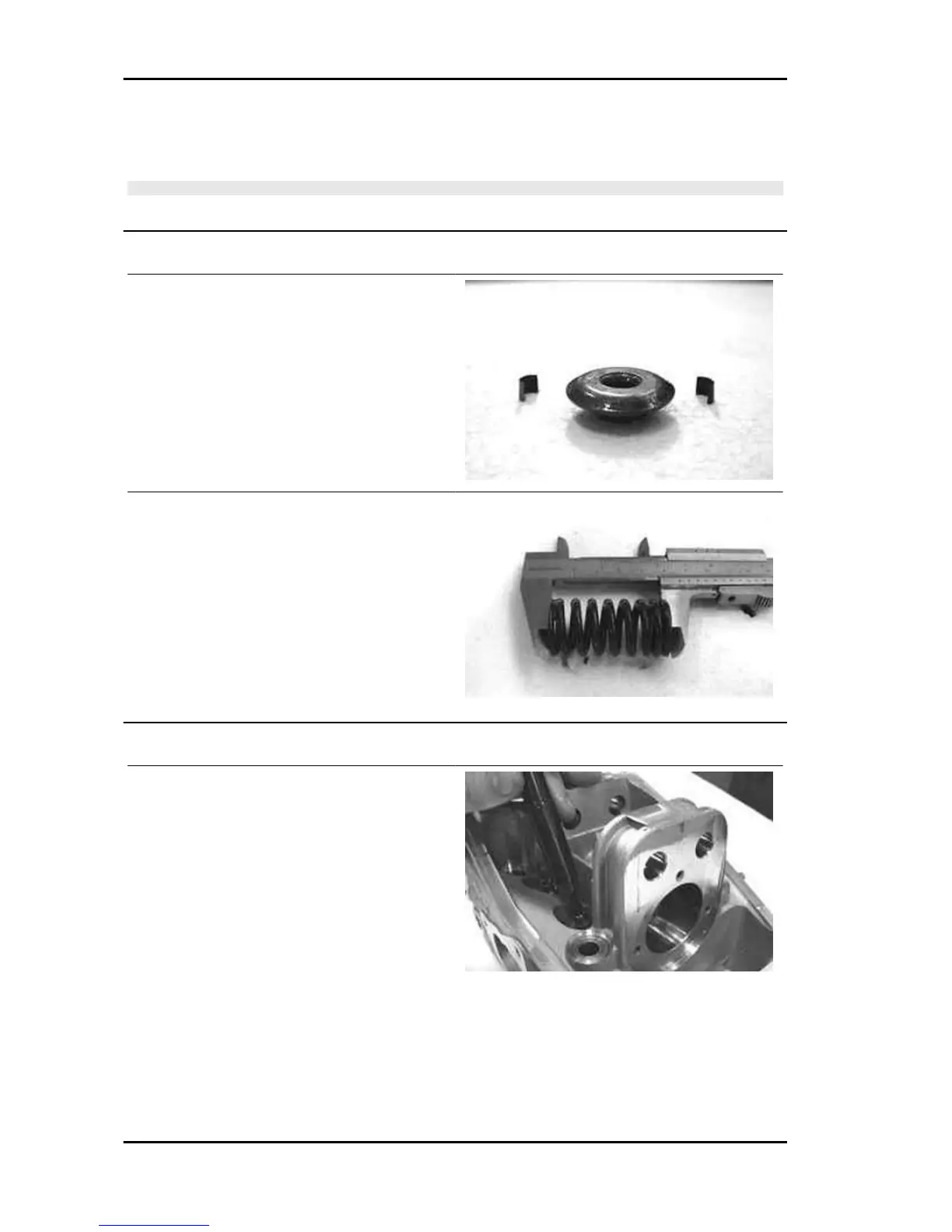

- Measure the unloaded spring length.

Characteristic

Standard length:

44.4 mm

Admissible limit after use:

42.4 mm

Refitting the valves

- Place the valve spring support washers on the

head.

- Alternately insert the 4 oil guards using the spe-

cial tool.

- Lubricate the oil guards and the valve guides.

Specific tooling

020306Y Punch for assembling valve seal

rings

Engine MP3 400 i.e.

ENG - 66

Loading...

Loading...