N.B.

MAIN BEARINGS CANNOT BE MODIFIED.

The connecting rod cannot be replaced. To check the connecting rod small end diameter, see chapter

"Thermal unit and timing system".

- When cleaning the crankshaft, be careful to prevent any impurity from entering into the shaft lubrication

hole.

N.B.

IN CASE OF REPLACEMENT OF A CRANKSHAFT CONSISTING OF TWO HALF-SHAFTS OF DIF-

FERENT CATEGORY, REPLACE THE TWO HALF-CRANKCASES AS WELL, COUPLING THE TWO

COMPONENTS (SHAFT AND CRANKCASE) WITH THE SAME CATEGORY.

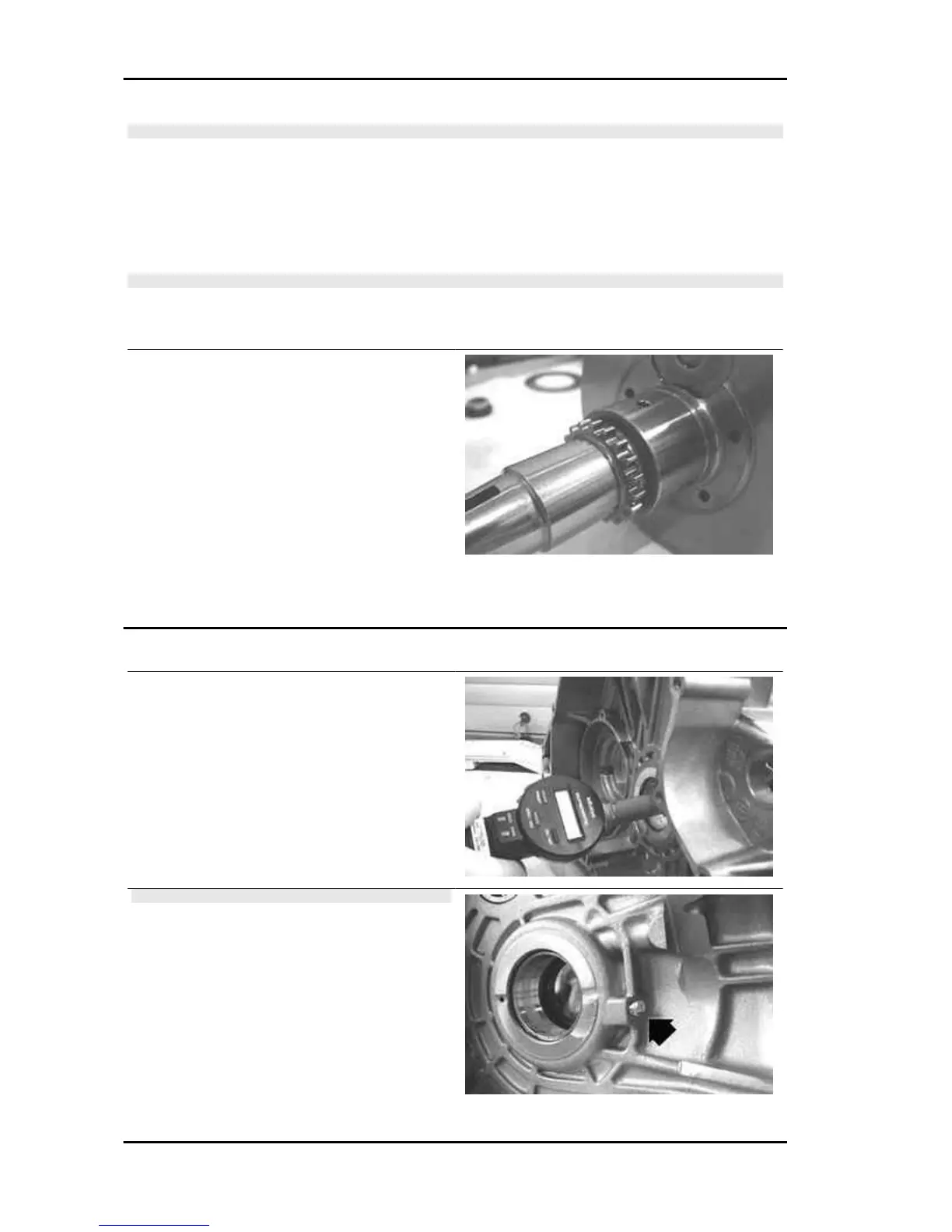

- To check the gearing of the crankshaft, see sec-

tion "Thermal unit and timing system".

See also

Cylinder assy. and timing system

Inspecting the crankcase halves

- Before proceeding to check the crankcase

halves, thoroughly clean the all surfaces and oil

ducts.

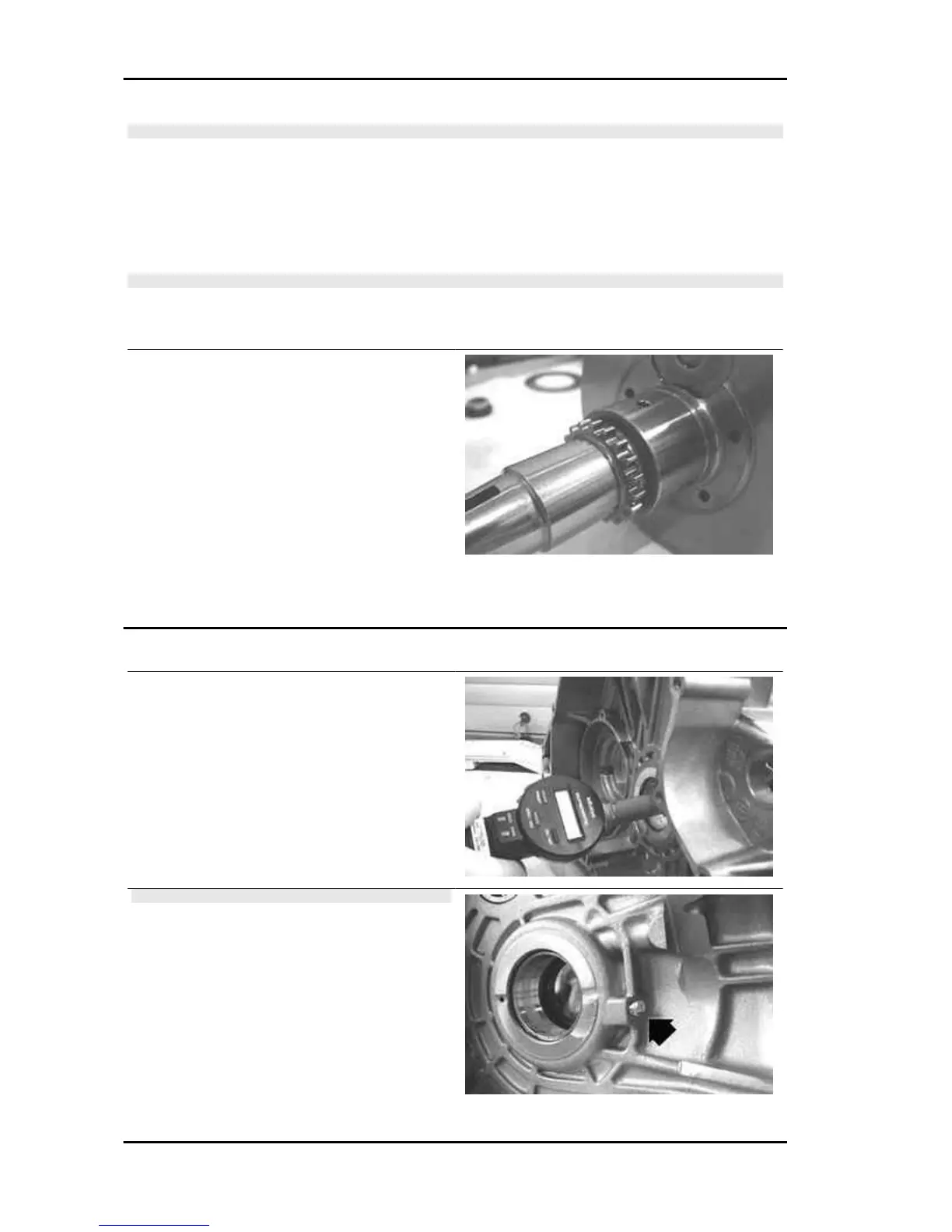

- For the transmission-side half-crankcase, special

attention should be given to the bushings, to the

cooling jet on the transmission side (see figure)

and to the lubrication duct.

N.B.

THE JET IS FED THROUGH THE MAIN BUSH-

INGS. PROPER OPERATION OF THIS COMPO-

NENT IMPROVES PISTON CROWN COOLING.

CLOGGING HAS EFFECTS THAT ARE DIFFI-

CULT TO DETECT (PISTON TEMPERATURE

INCREASE). FAILURE OR LEAKS CAN CAUSE

A CONSIDERABLE DROP IN THE LUBRICA-

TION PRESSURE FOR MAIN BUSHINGS AND

CONNECTING ROD .

Engine MP3 400 i.e.

ENG - 86

Loading...

Loading...