Specific tooling

020074Y Support base for checking crankshaft alignment

- If the crankshaft - crankcase axial clearance is higher than the standard value and the crankshaft

exhibits no irregularity, the problem is caused by wear or by a wrong machining on the engine crankcase.

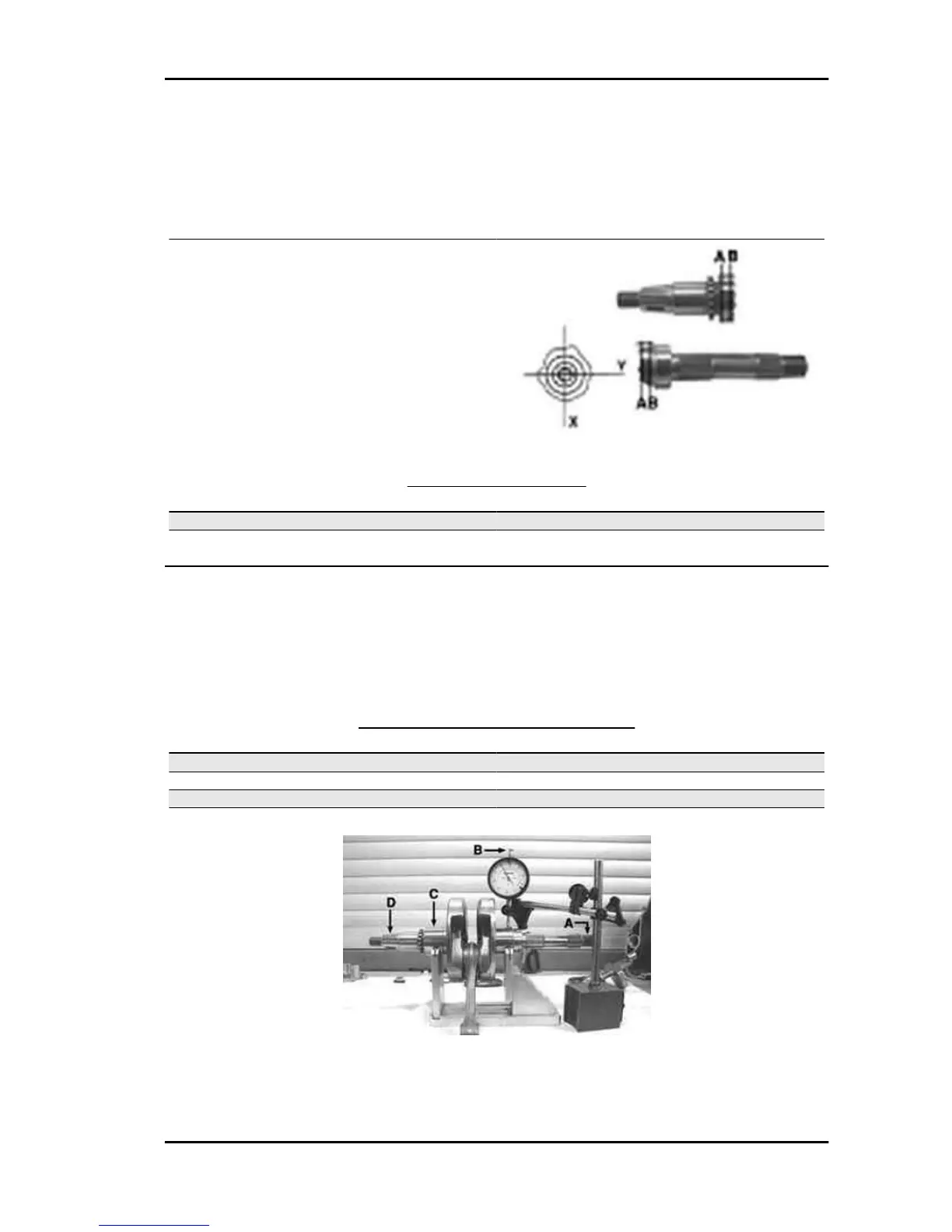

- Check the diameters of both the bearings of the

crankshaft in accordance with the axes and surfa-

ces shown in the figure. Half-shafts are classified

into two categories, Cat. 1 and Cat. 2.

STANDARD DIAMETER

Specification Desc./Quantity

Cat. 1 40.010 ÷ 40.016

Cat. 2 40.016 ÷ 40.022

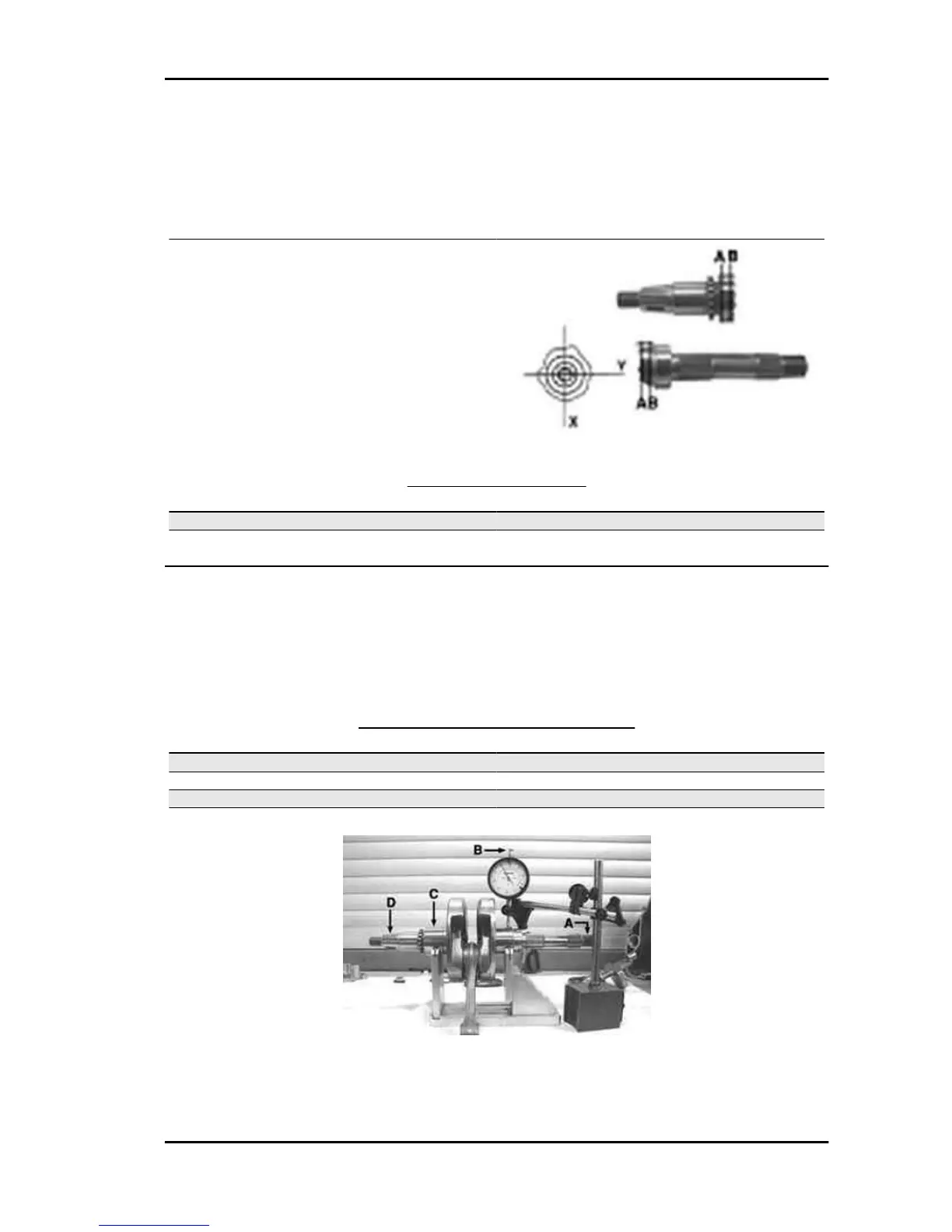

Inspecting the crankshaft alignment

- Install the crankshaft on the support and measure the displacement at the 4 points shown in the figure.

Specific tooling

020074Y Support base for checking crankshaft alignment

MAX ADMISSIBLE DISPLACEMENT:

Specification Desc./Quantity

A = 0.15 mm

B = 0.01 mm

C = 0.01 mm

D = 0.10 mm

- Check that the driving shaft cone, the tab seat, the oil seal capacity, the toothed gear and the threaded

tangs are in good working order.

- In case of failures, replace the crankshaft.

MP3 400 i.e. Engine

ENG - 85

Loading...

Loading...