Removing the clutch

- To remove the clutch with the driven pulley it is

necessary to use the special tool;

- Arrange the tool with the mean pins screwed in

position "E" on the inside;

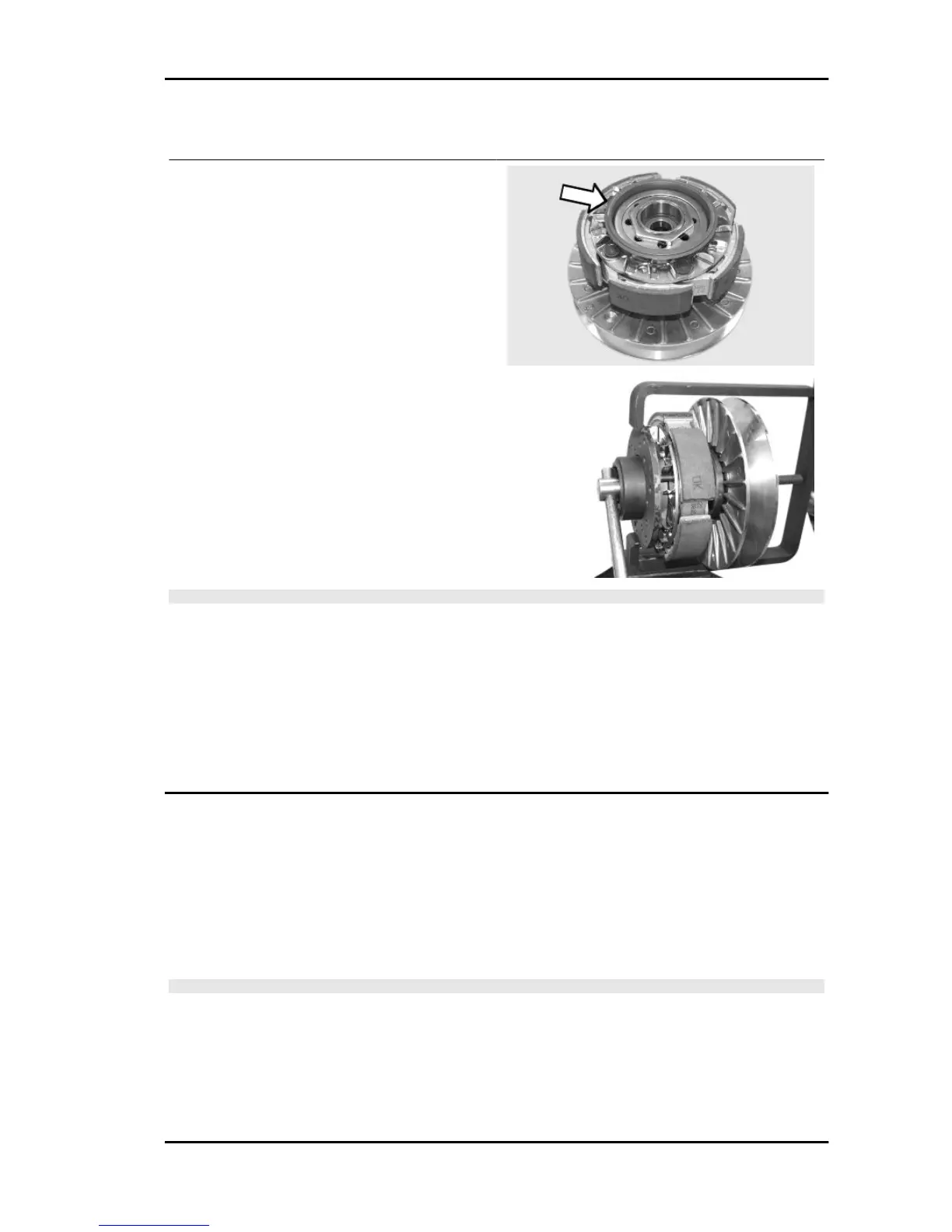

- Fit the adapter ring to the clutch assembly as

shown in the photograph.

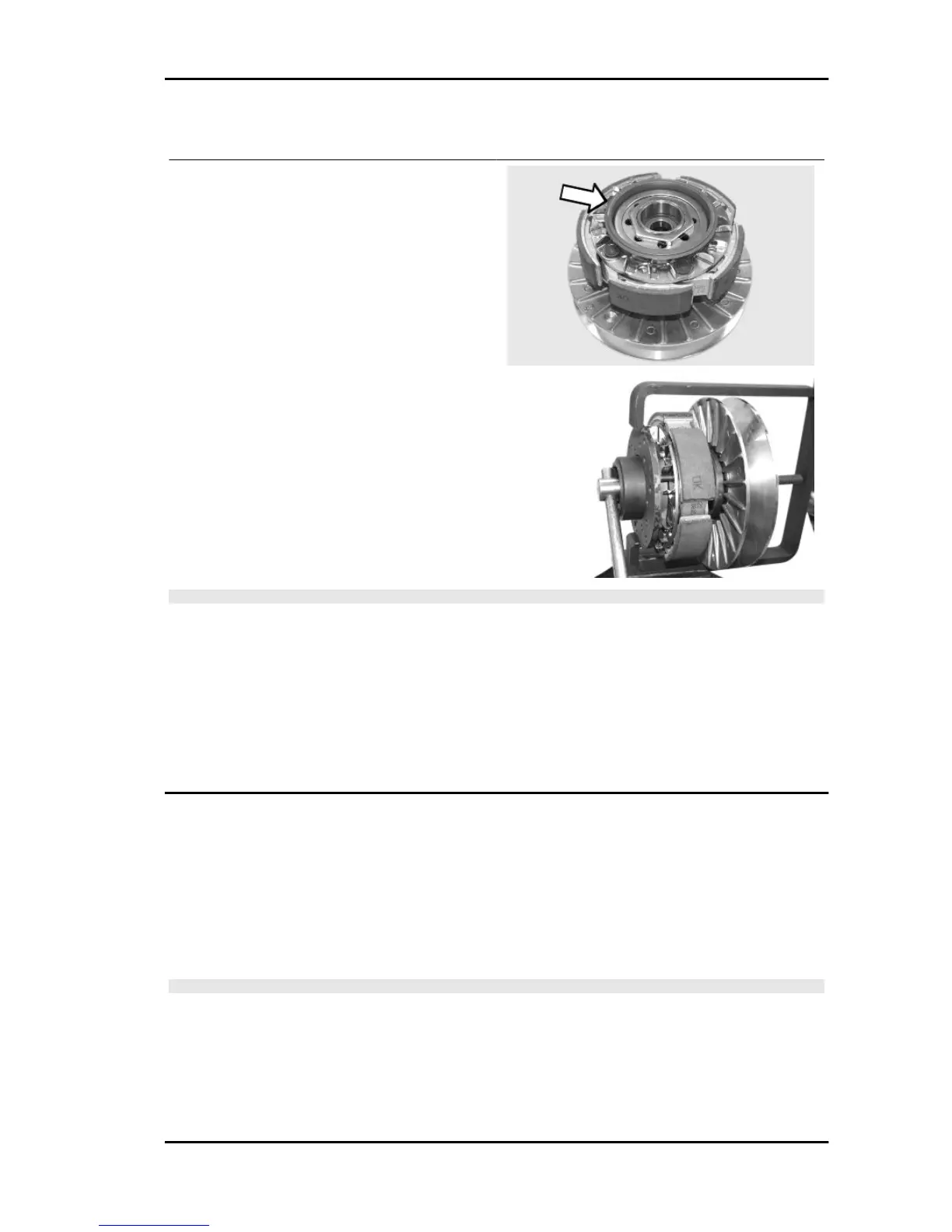

- Install the driven pulley unit onto the tool inserting

the pins into the ventilation holes;

- Move the rear stop screw in abutment against the

fixed driven pulley as shown in the figure.

CAUTION

THE TOOL SHOULD BE FIRMLY SECURED IN A VICE USING THE SPECIAL TOOL. DO NOT

TIGHTEN THE REAR SCREW TOO MUCH AS THIS COULD CAUSE AN IRREVERSIBLE TOOL

DEFORMATION.

USING THE SPECIAL 55-MM WRENCH, REMOVE THE FASTENING RING NUT.

LOOSEN THE TOOL SCREW AND DISASSEMBLE THE DRIVEN PULLEY UNIT, CLUTCH, SPRING

WITH SHEATH.

Specific tooling

020444Y Tool for fitting/ removing the driven pulley clutch

Inspecting the clutch

- Check the thickness of the clutch mass friction material.

Characteristic

Minimum thickness permitted:

1 mm

- The masses must not show traces of lubricants. Otherwise, check the driven pulley unit seals.

N.B.

UPON RUNNING-IN, THE MASSES MUST EXHIBIT A CENTRAL CONTACT SURFACE AND MUST

NOT BE DIFFERENT FROM ONE ANOTHER. VARIOUS CONDITIONS CAN CAUSE THE CLUTCH

TO TEAR.

MP3 400 i.e. Engine

ENG - 7

Loading...

Loading...