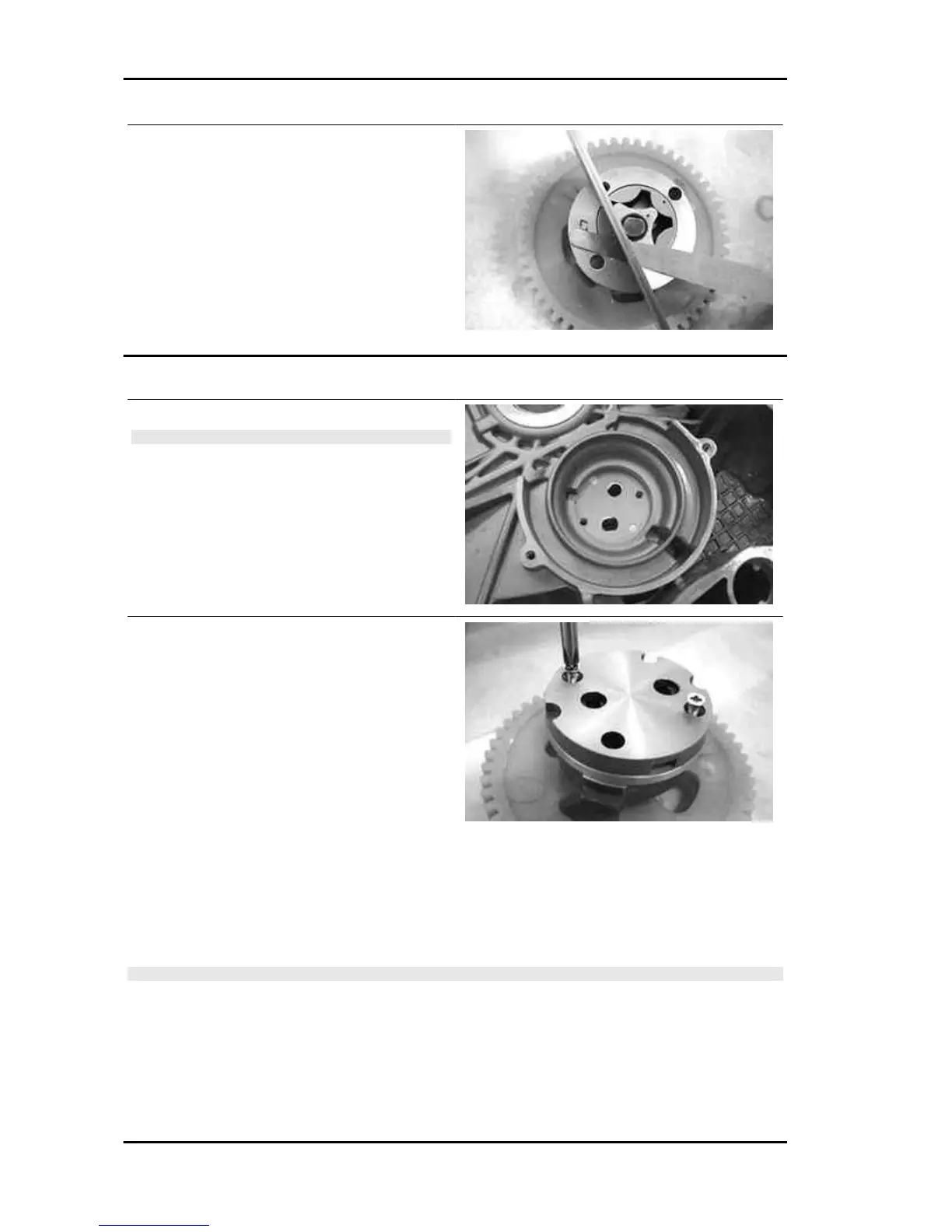

- Check the rotor axial clearance using a rectified

bar as reference plane, as shown in the figure.

Characteristic

Limit values admitted:

0.1 mm

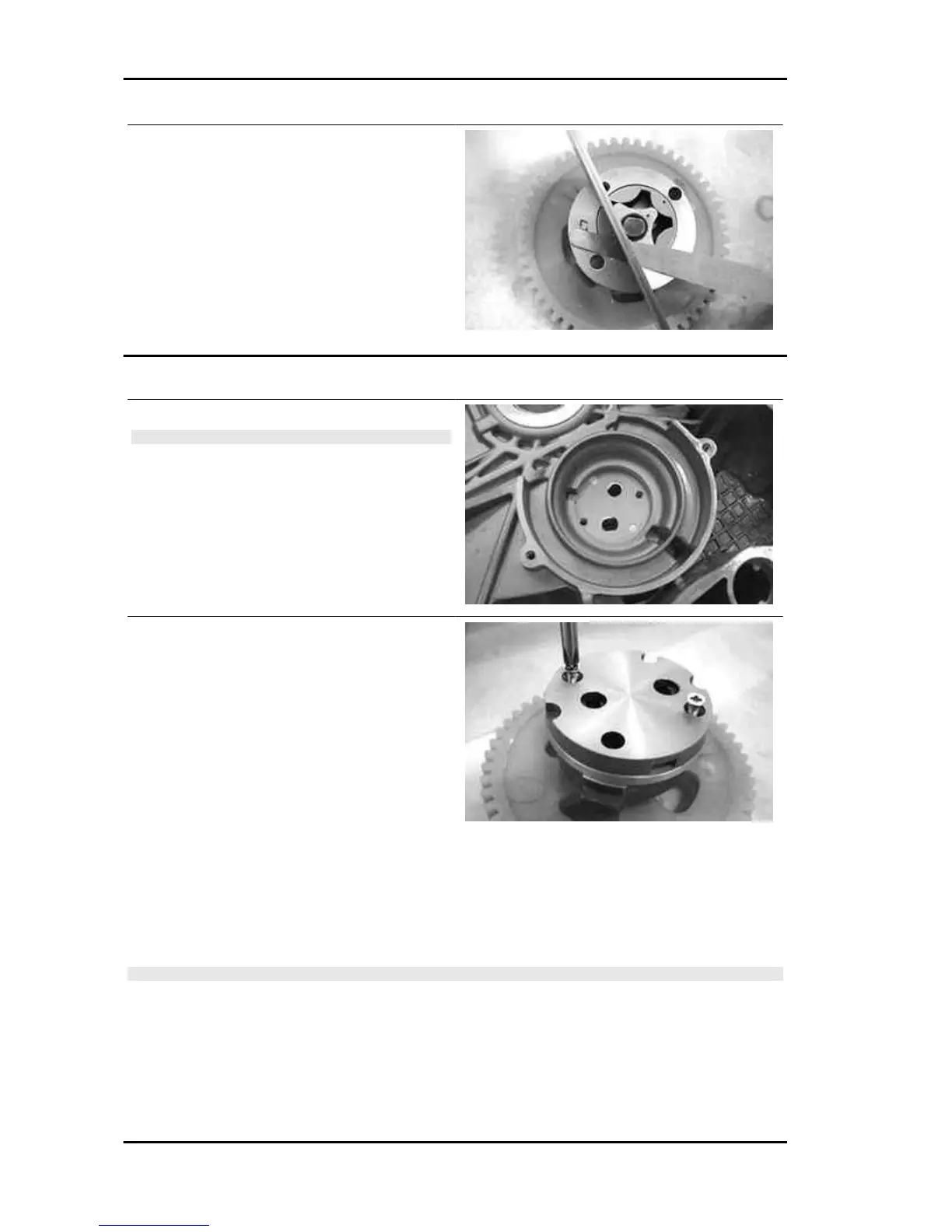

Refitting

- Make sure the gasket is in the correct position.

N.B.

THE TOOTH OF THE GASKET MUST BE IN ITS

SEAT.

- Lubricate the internal rotors.

- Check there are no signs of scoring or wear on

the oil pump cover.

- If non-conforming values or signs of wear are

found, replace the pump.

- Fit the pump cover in the position that permits the

crankcase fixing screws to be aligned.

- Tighten the two fastening screws to the prescri-

bed torque.

Locking torques (N*m)

Oil pump cover screws 0.7 ÷ 0.9

- Insert the oil pump with gear

- Insert the 2 retaining screws through the slots on the gear and tighten to the prescribed torque.

N.B.

THE ASSEMBLY POSITION OF THE PUMP IS FIXED BY INSTALLATION OF THE SCREWS.

Engine MP3 400 i.e.

ENG - 102

Loading...

Loading...