4.14

FUEL INJECTION

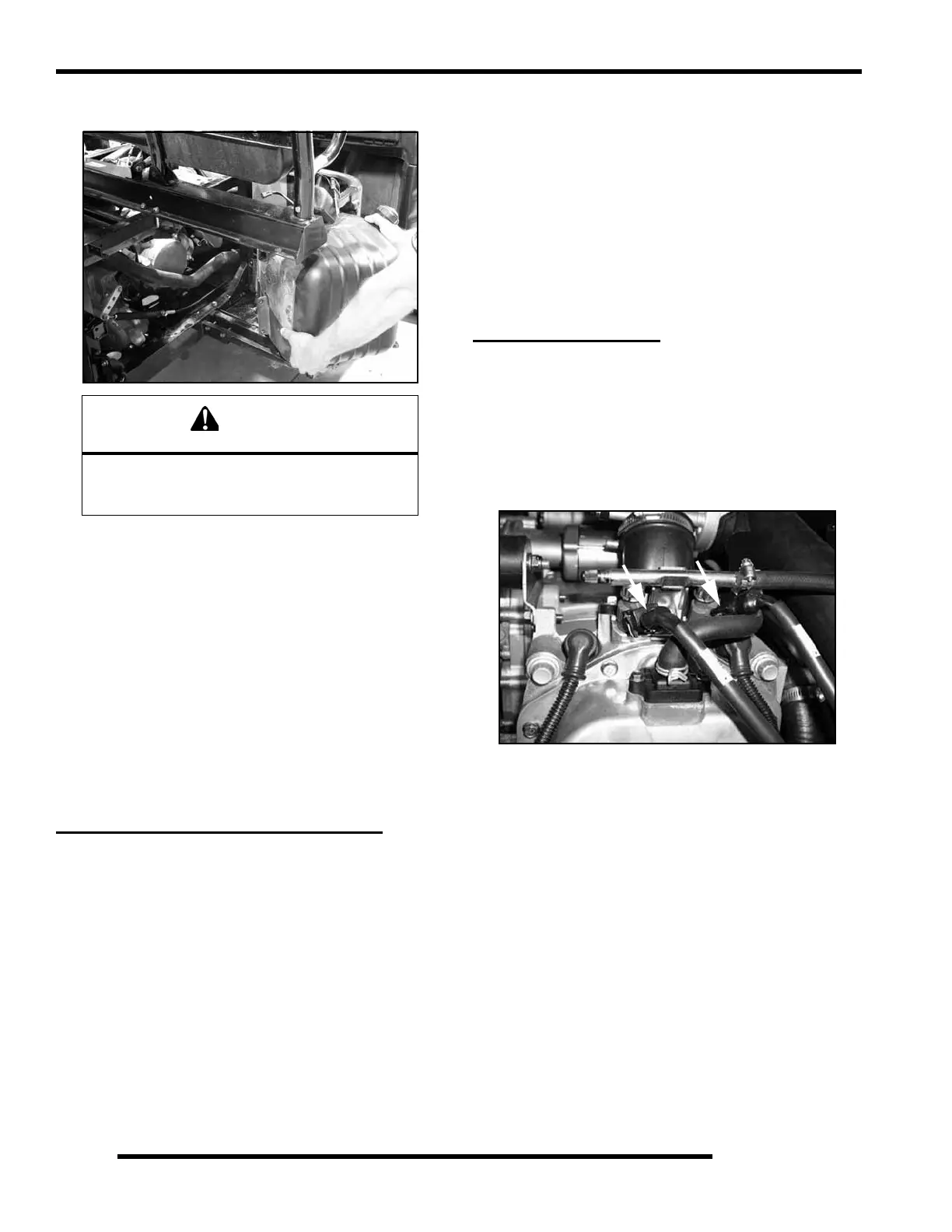

9. Reinstall the fuel cap and carefully pull the fuel tank out the

RH side of the frame.

Fuel Tank Installation

1. Reinstall the pump/tank assembly.

2. Reinstall the four fuel tank mounting bolts that were

removed.

3. Reconnect the electrical harness. Install the fuel line and

vent line and verify they are secure.

4. Reinstall the RH rear fender.

5. Reconnect the negative battery cable. Test the fuel pump

by turning on the key and listening for the pump to activate.

FUEL PRESSURE REGULATOR

Operation Overview

The fuel pressure regulator maintains the required operating

system pressure of 39 psi + 3psi. A rubber-fiber diaphragm

divides the regulator into two separate sections-, the fuel

chamber and the pressure regulating chamber. The pressure

regulating spring presses against the valve holder (part of the

diaphragm), pressing the valve against the valve seat. The

combination of atmospheric pressure and regulating spring

tension equals the desired operating pressure. Any time the fuel

pressure against the bottom of the diaphragm exceeds the

desired (top) pressure, the valve opens, relieving the excess

pressure, returning the excess fuel back to the tank.

Fuel Pressure Regulator Test

Refer to the “FUEL PUMP TEST” procedure.

See “Fuel Pump Test” on page 4.12.

Fuel Pressure Regulator Replacement

The regulator is a sealed, non-serviceable assembly. If it is

faulty, the pump assembly must be replaced. Refer to the Fuel

Pump / Tank Assembly Replacement procedure.

FUEL INJECTORS

Operation Overview

NOTE: All EFI units utilize quick connect fuel lines.

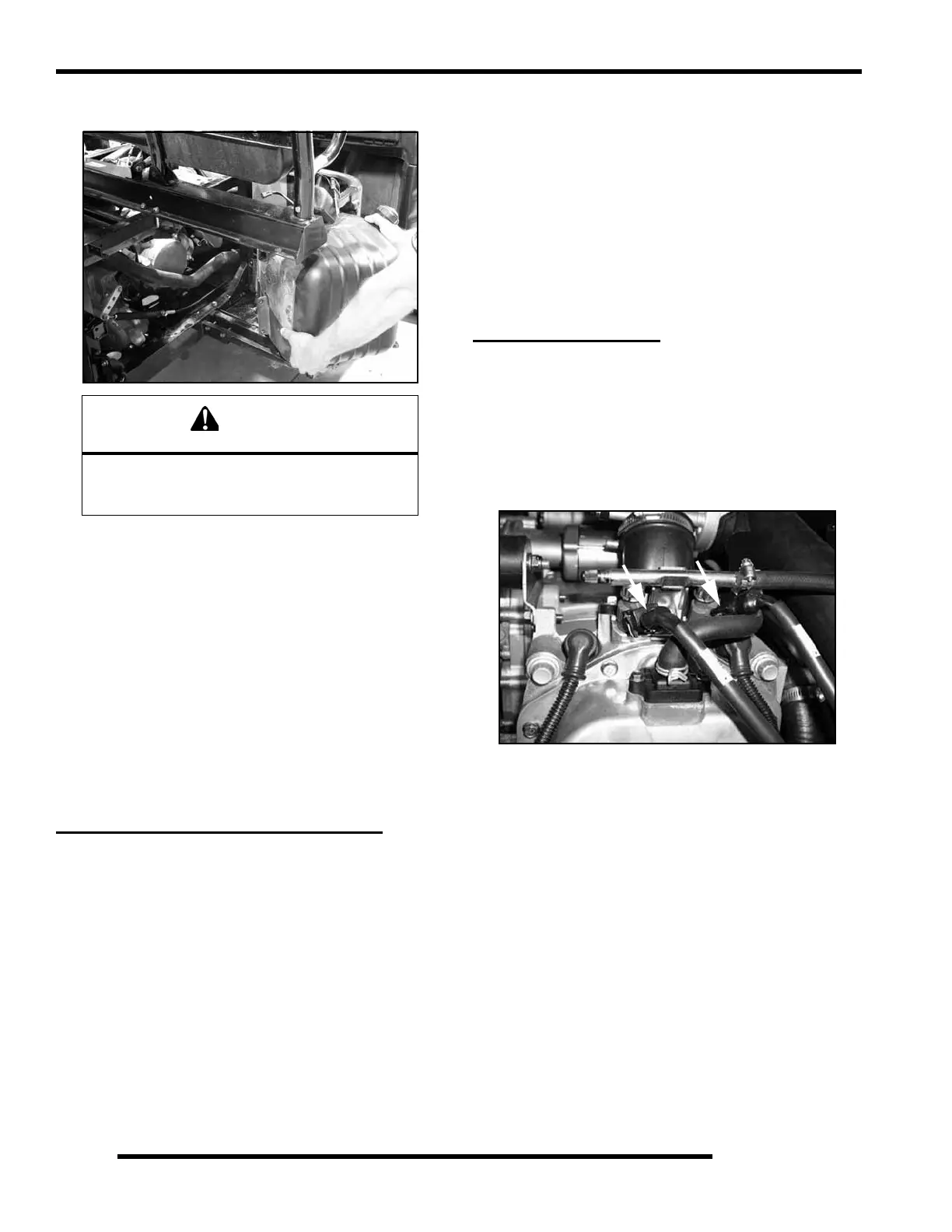

The fuel injectors mount into the intake manifold, and the fuel

rail attaches to them at the top end. Replaceable O-rings on both

ends of the injector prevent external fuel leaks and also insulate

it from heat and vibration.

When the key switch is on, the fuel rail is pressurized, and

voltage is present at the injector. At the proper instant, the ECU

completes the ground circuit, energizing the injector. The valve

needle in the injector is opened electromagnetically, and the

pressure in the fuel rail forces fuel down through the inside. The

“director plate” at the tip of the injector (see inset) contains a

series of calibrated openings which directs the fuel into the

intake port in a cone-shaped spray pattern.

The injector is opened and closed once for each crankshaft

revolution, however only one-half the total amount of fuel

needed for one firing is injected during each opening. The

amount of fuel injected is controlled by the ECU and determined

by the length of time the valve needle is held open, also referred

to as the “injection duration” or “pulse width”. It may vary in

length from 1.5-8 milliseconds depending on the speed and load

requirements of the engine.

WARNING

Wear safety goggles while performing this

procedure, failure to do so could result

in serious injuries.

Loading...

Loading...