7.5

FINAL DRIVE

7

Hub Installation

1. Inspect the hubstrut bearing surface for wear or damage.

2. Apply grease to drive axle spindle.

3. Install spindle through the backside of the hubstrut. Install

the hub onto the spindle.

4. Apply grease to washer and install with domed side out.

5. Install spindle nut and tighten to specification.

6. Install a new cotter pin. Tighten nut slightly if necessary

to align cotter pin holes.

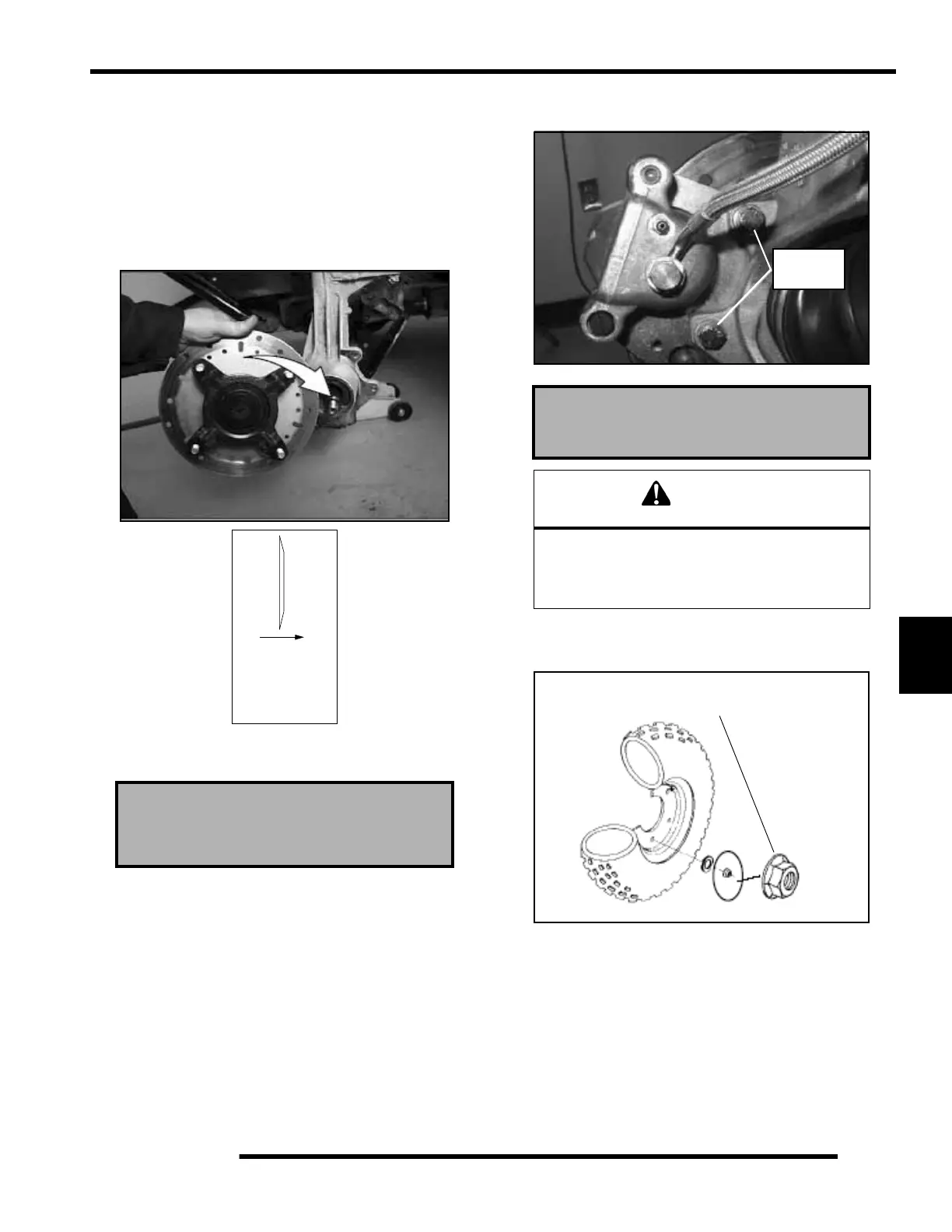

7. Rotate wheel and check for smooth operation. Bend both

ends of cotter pin around end of spindle in different

directions.

8. Install hub cap.

9. Rotate hub. It should rotate smoothly without binding or

rough spots or side play.

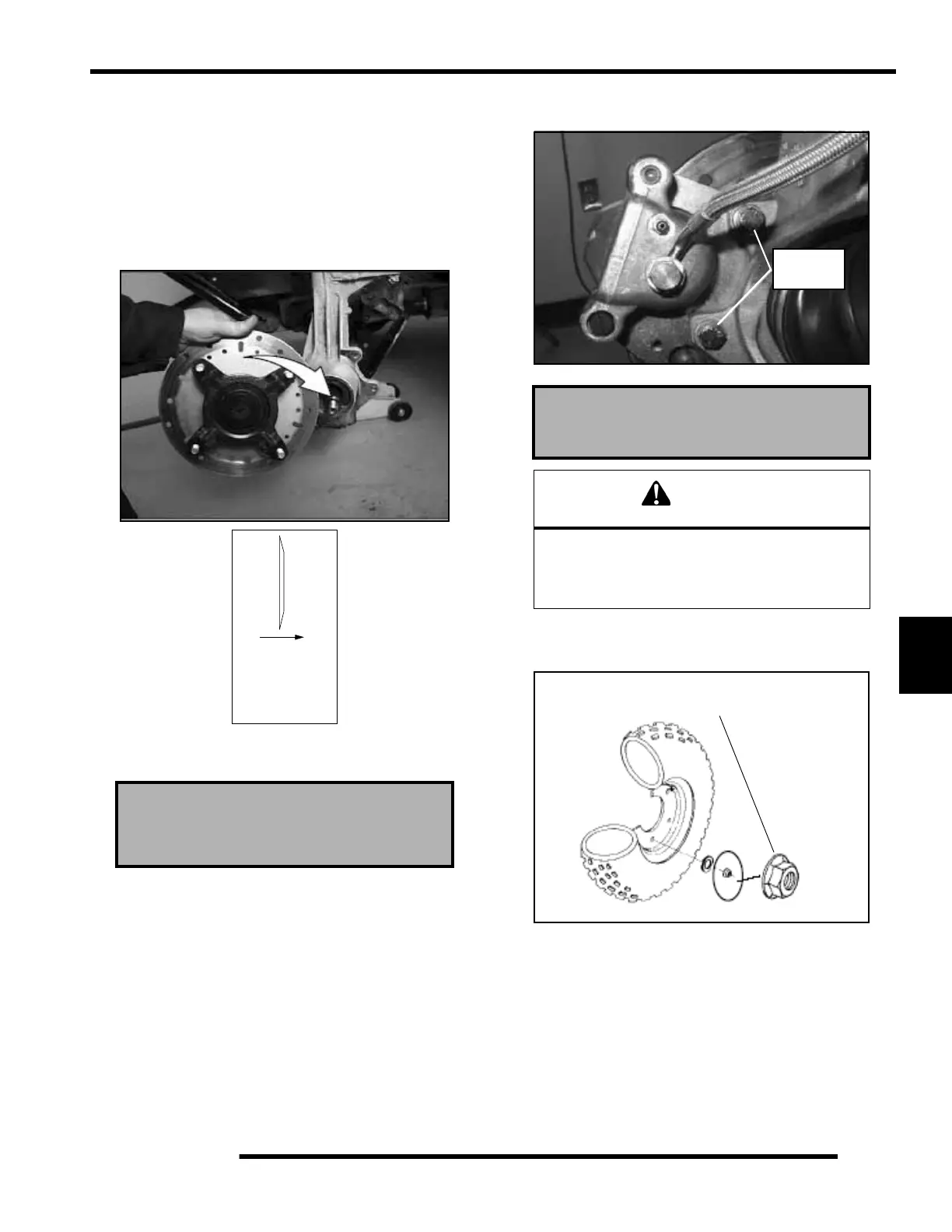

10. Install brake caliper using new bolts. Tighten bolts to

specified torque.

11. Install wheel, washers, wheel nuts, and tighten evenly in a

cross pattern to specified torque.

Refer to “Torque Specifications” on Page 7.3

Spindle Nut Torque:

70 ft. lbs. (95 Nm)

Out

Cone

Washer

Brake Caliper Bolt Torque

18 ft. lbs. (24 Nm)

CAUTION

New bolts have a pre-applied locking agent

which is destroyed upon removal. Always use

new brake caliper mounting bolts

upon assembly.

18 ft. lbs.

(24 Nm)

Flange Nuts:

Flat side against wheel

Loading...

Loading...