4.18

FUEL INJECTION

3. If voltage varies with throttle movement, continue on to

step 3 and measure the idle air flow reading. If the sensor

does not function correctly, replace it.

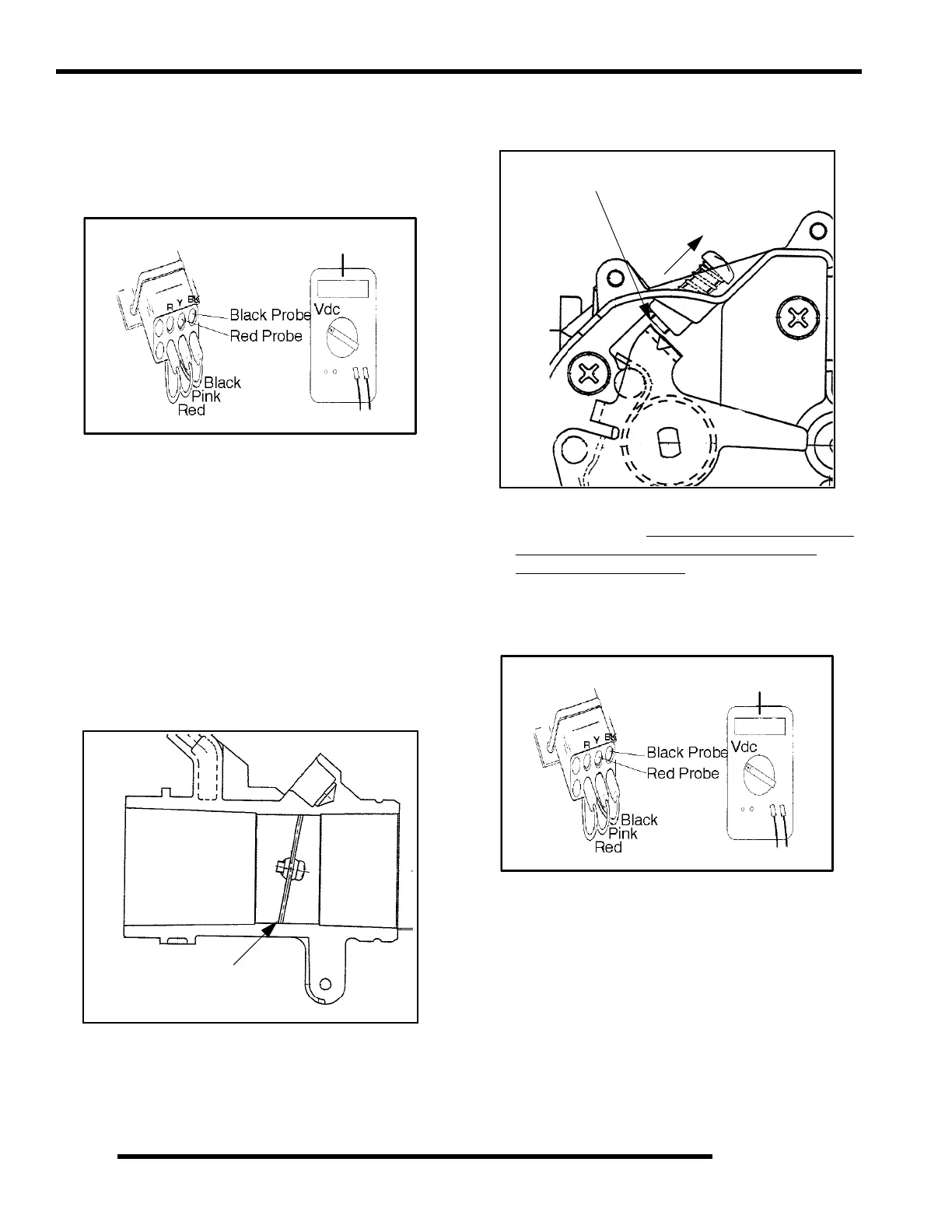

4. With voltmeter still attached to the TPS Test Adapter

Harness (PU-47082) as shown below, the voltmeter should

read .710 ± .01 volts at idle position.

5. If the voltage does not read within the specification,

“TPS Initialization” will need to be performed.

TPS Initialization

NOTE: The correct position of the TPS is

established and set at the factory. Use this

procedure only if the TPS was repositioned,

replaced or loosened.

STEP 1

Establishing zero offset voltage: This step is crucial as it sets

the TPS position using a fixed physical stop. This will insure

that the correct offset voltage is reached once the correct throttle

body flow is set.

• Remove cover and disconnect throttle cable from

throttle cam.

• With engine off, back out air flow screw until it no

longer is in contact with throttle plate cam. The throttle

plate should seal off throttle bore completely.

• Open and close throttle plate a couple of times to ensure

full throttle closing. Do not snap closed, as this could

cause unnecessary throttle plate to throttle body

interference and/or damage.

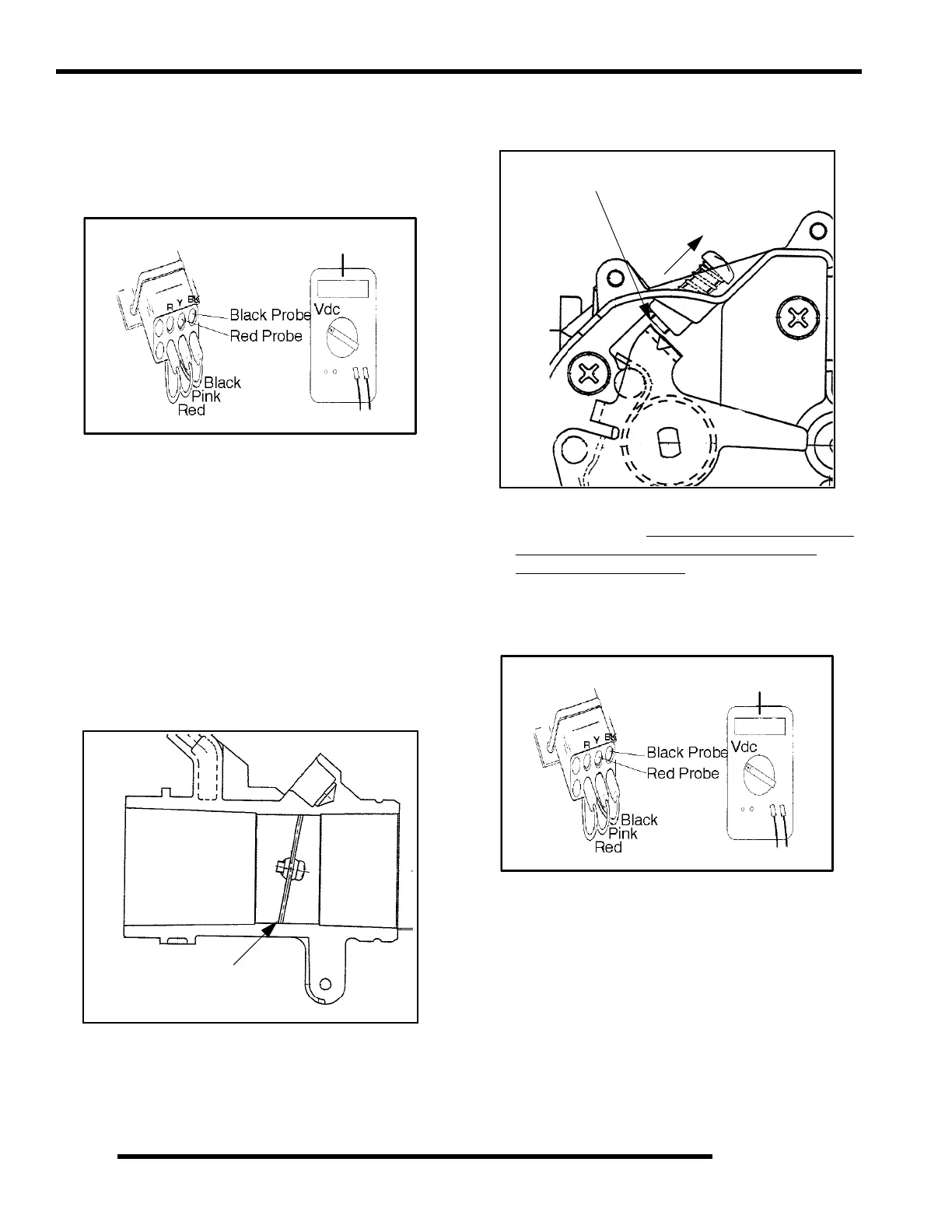

• Set up the TPS Test Adapter Harness (PU-47082)

according to the instructions. Verify that the 9 volt

battery is new. See illustration below.

• Using a voltmeter attached to the TPS Tester Harness

(PU-47082), check the voltage output of the TPS. It

should read .528 .01 volts.

• If it does not read .528 .01 volts, loosen the screw

holding the TPS to the throttle body. Rotate TPS until

voltmeter reads .528 .01 volts.

• Retighten TPS mounting screw, and verify the voltage

did not change. If changed, repeat the previous steps.

TPS Tester Adapter

Harness- PU-47082

Should Read: .710 V

.710

Throttle Plate

Must Be Closed

Back Air Flow Screw Out

Until No Contact is Made

TPS Tester Adapter

Harness- PU-47082

.528

Should Read: .528 V

Loading...

Loading...