21

eRev. [Major Version]1.01.0 8/9/2023

KrosFlo® KR2i Real-Time Process Management (RPM™) System

8. Pump Head Setup and Operation

8.1 Introduction

The Easy-Load and High-Performance Pump Heads are designed to be used with the TFF systems as a simple peristaltic pump

system. The Pump Heads accept different tubing sizes for a wide range of flow rates, and the unique designs and automatic tubing

retention allow for quick tubing changes.

8.2 Tubing Specifications

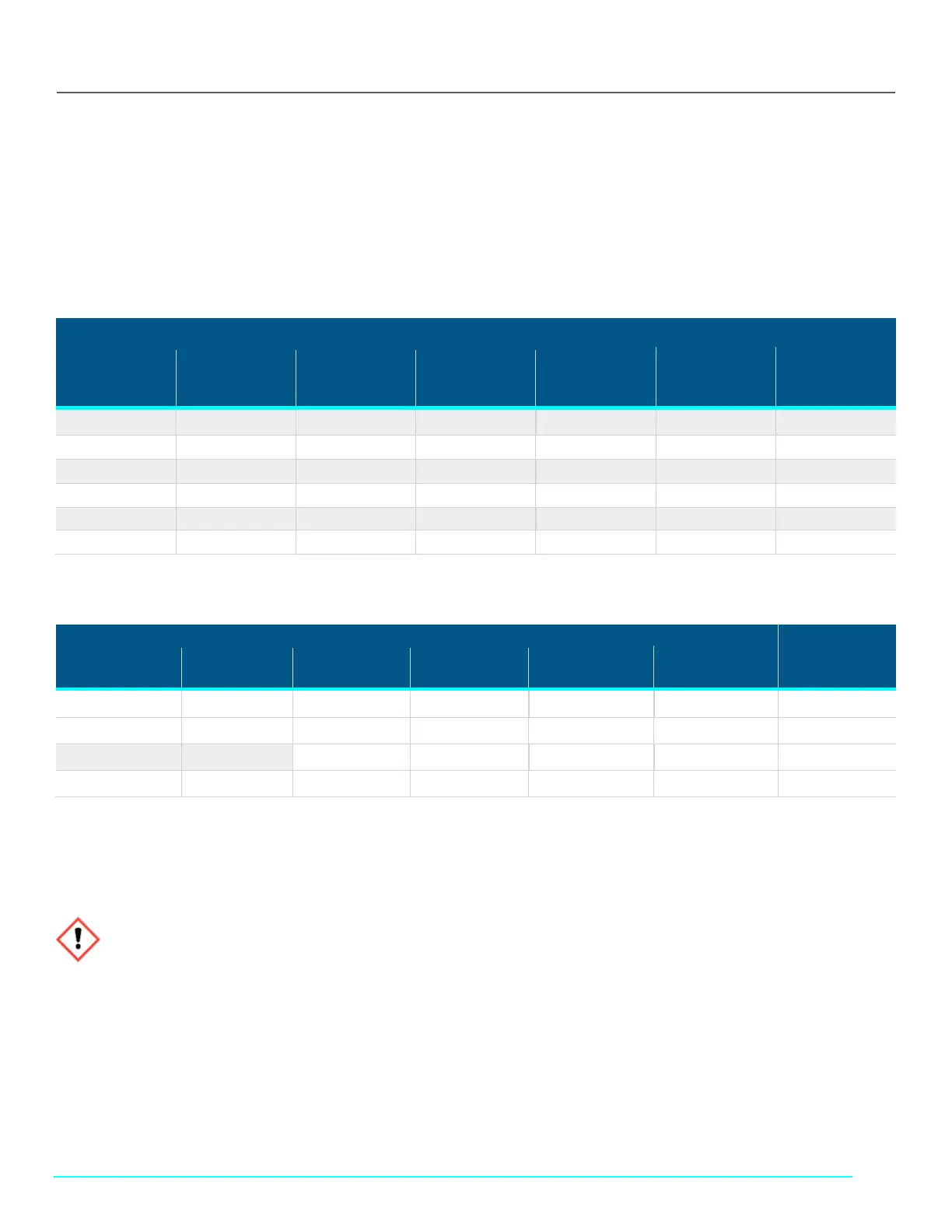

Table 12. ACR2-H3I-01N Typical Flow, Pressure, and Vacuum Data – 3 roller pumps

MasterFlex®

L/S® Tubing

Flow Rate* Discharge Pressure*

Vacuum*

@ 600 rpm

in (mm) Hg

Suction Lift*

@ 600 rpm

ft (m) H

2

O

@ 1 rpm

mL/rev

@ 600 rpm

mL/min

Continuous

psig (bar)

Inttermittent

psig (bar)

L/S® 13 0.06 36 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S® 14 0.22 130 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S® 16 0.8 480 25 (1.7) 40 (2.7) 26 (660) 29 (8.8)

L/S® 25 1.7 1000 20 (1.4) 35 (2.4) 26 (660) 29 (8.8)

L/S® 17 2.8 1700 15 (1.0) 20 (1.4) 20 (510) 22 (6.7)

L/S® 18 3.8 2300 10 (0.7) 15 (1.0) 20 (510) 22 (6.7)

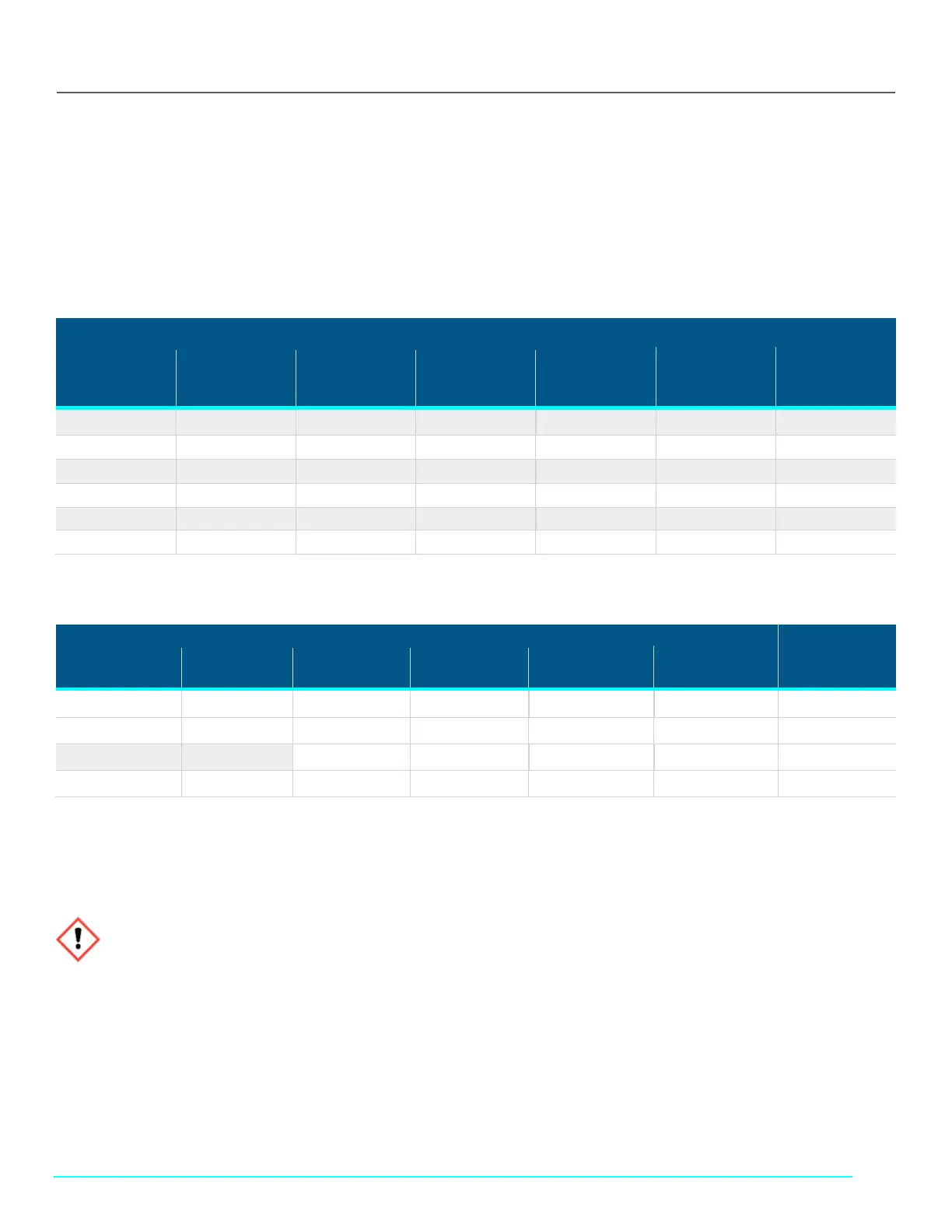

Table 13. ACR2-H4I-01N Typical Flow, Pressure, and Vacuum Data – 3 roller pumps

MasterFlex®

L/S® Tubing

@ 600 rpm

@ 600 rpm ft

@ 600 rpm

Continuous psig

Intermittent psig

L/S® 15 1.7 1000 25 (1.7) 30 (2.7) 26 (660) 29 (8.8)

L/S® 24 2.8 1700 25 (1.7) 30 (2.7) 26 (660) 29 (8.8)

L/S® 35 3.8 2300 20 (1.4) 25 (2.4) 26 (660) 29(8.8)

L/S® 36 4.8 2900 15 (1.0) 20 (1.4) 24 (610) 27 (8.3)

*Specifications are valid for NORPRENE®, PHARMED®, and TYGON® tubing. Values will be less with silicone, C-FLEX®, and Viton®. Flow rate and

discharge pressure will vary based on tubing size, formulation, and operating temperature. The tables above are only a guide.

8.3 KR2i Installation and Removal

1. If mounting plate is not attached to the pump drive, attach it using the provided four Phillips head screws (see Figure 7).

WARNING: Stop the pump drive before installing or removing the pump head from the drive.

Loading...

Loading...