43

eRev. [Major Version]1.01.0 8/9/2023

KrosFlo® KR2i Real-Time Process Management (RPM™) System

12. Troubleshooting

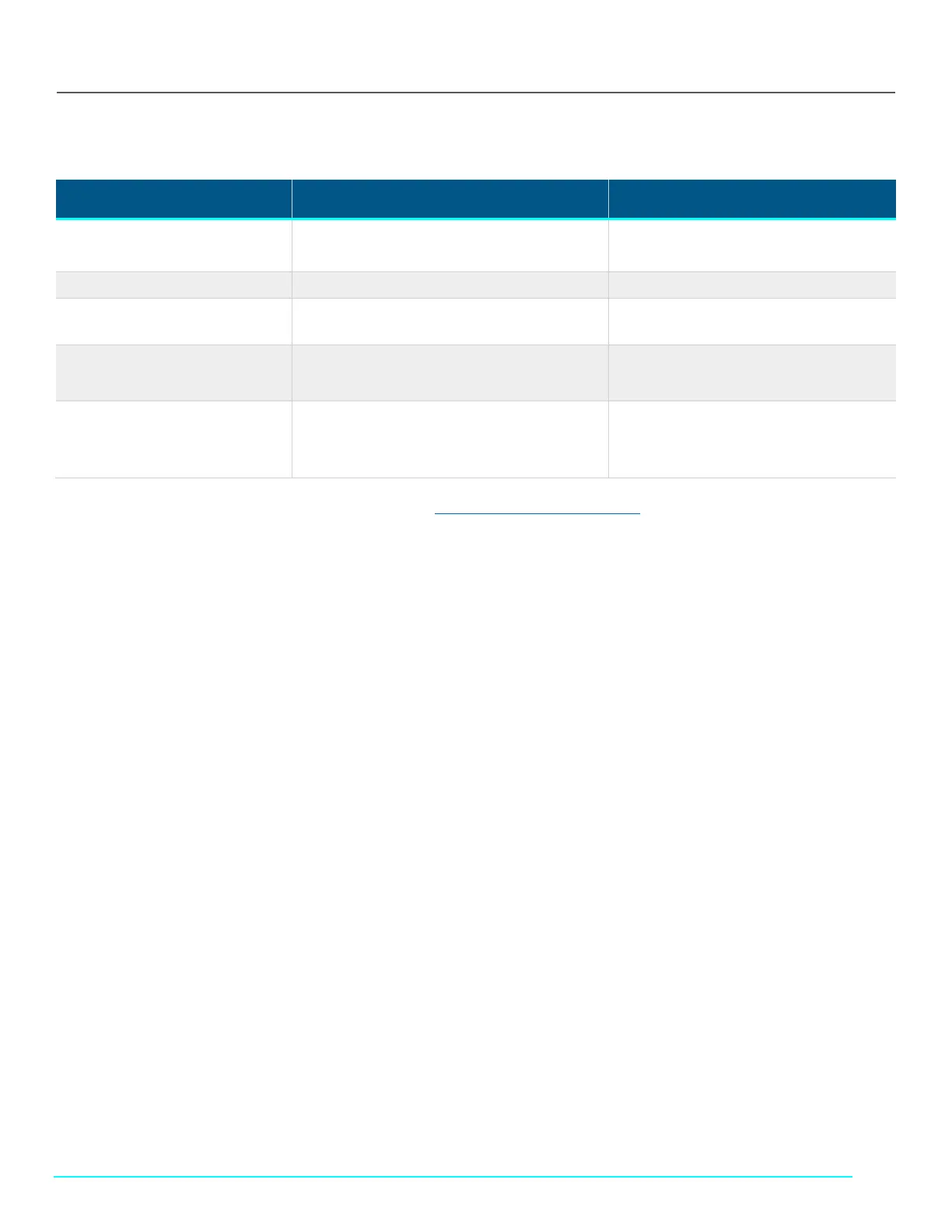

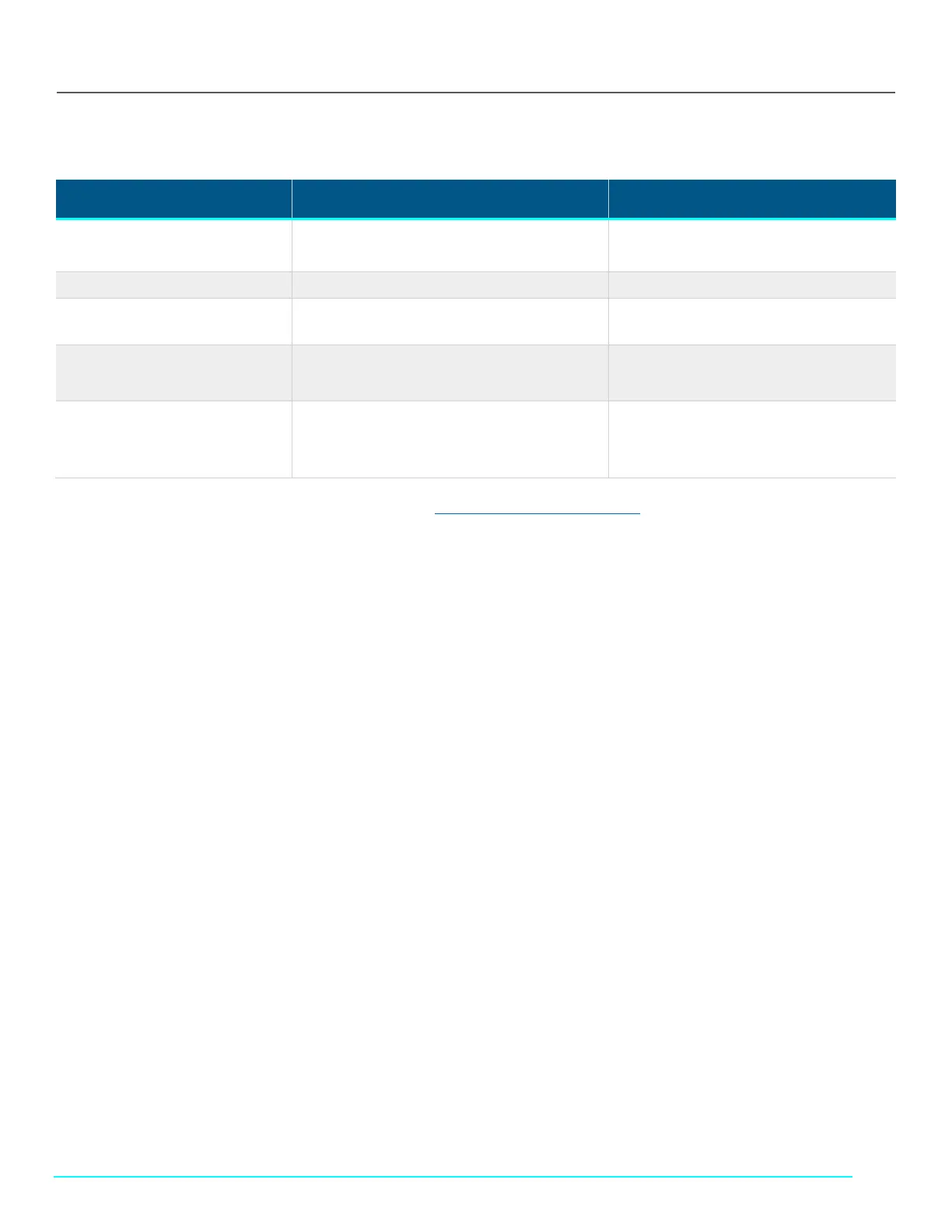

Table 16. Troubleshooting

Symptom Diagnosis Remedy

1. Pressure Sensor readings are

wrong (either -9.9 psi or >35 psi

when no pressure is on them)

Pressure sensor octopus cable not functioning or

pressure sensor broken

Replace Octopus Cable and/or pressure sensor

2. Scale not reading properly Refer to manufacturer’s scale manual. Refer to manufacturer’s scale manual.

3. Pump not working correctly

Refer to pump manufacturer’s manual,

troubleshooting section.

Refer to pump manufacturer’s manual,

troubleshooting section.

4. Process ending early or late in

the DV or CF auto modes

Input for the holdup volumes is wrong

Enter the correct feed holdup and permeate

holdup volumes and select if they are empty or

full when starting the process

5. Process ending early when using

the Conductivity or UV sensors

(fixed pathlength sensors for

auto modes)

Sensor not full of proper liquid

Conductivity sensor should be filled with same

buffer that sample is in when starting the

process. UV sensor should be zeroed with the

same buffer sample is in.

For further Technical Assistance, please contact Repligen at analytics-support@repligen.com

or (908) 707-1009.

Loading...

Loading...