PRINTER ENGINE SERVICE MODE

G065 5-10 SM

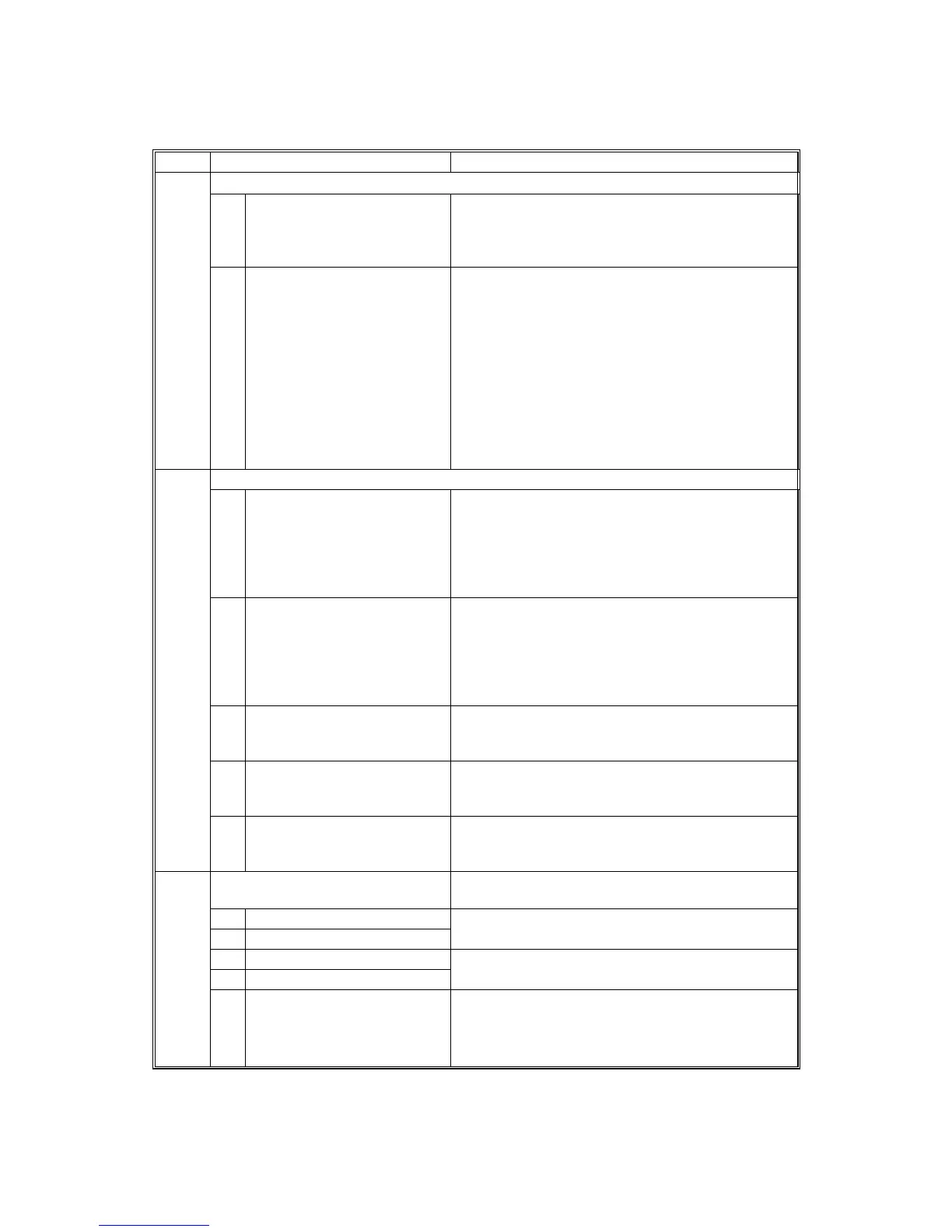

2. Drum (SP2000-00)

SP2 Mode Number Function and [Setting]

Charge Roller Bias Adjustment

01 Image Pattern

Adjusts the voltage applied to the charge roller

for the image area to maintain a charge of –800

V on the OPC drum surface.

[–1,000 ~ –2,000 / –1,480 V / 10 V step]

2001*

02 ID Sensor Pattern

Adjusts the voltage applied to the charge roller

when making the ID sensor pattern (for charge

roller voltage correction). The actual charge

roller voltage is this value plus the value of

SP2001-01.

[0 ~ 700 / 200 V / 10 V step]

The default is adjusted automatically based on

the number of prints.

00 K ~ 10 K: 200 V

10 K ~ 50 K: 230 V

50 K ~ 150 K: 340 V

Charge Roller Voltage

01 Correction 1

Adjusts the lower threshold value for the charge

roller correction. DFU

When the value of V

SP

/V

SG

is greater than this

value, the charge roller voltage increases by 30

V (e.g., from –1,480 to –1,510).

[0.1 ~ 1.0 / 0.85 / 0.05 step]

02 Correction 2 Adjusts the upper threshold value for the charge

roller correction. DFU

When the value of V

SP

/V

SG

is greater than this

value, the charge roller voltage decreases by 30

V (absolute value).

[0.1 ~ 1.0 / 0.9 / 0.05 step]

03 Adjustment 1 Adjusts the lower limit value for charge roller

voltage correction. DFU

[–1,000 ~ –2,000 / 1,480 V / 10 V step]

04 Adjustment 2

Adjusts the upper limit value for charge roller

voltage correction. DFU

[–1,000 ~ –2,000 / 2,000 V / 10 V step]

2005*

05 Step Adjusts the correction voltage adjustment step

size. DFU

[0 ~ 100 V / 30 V / 10 V step]

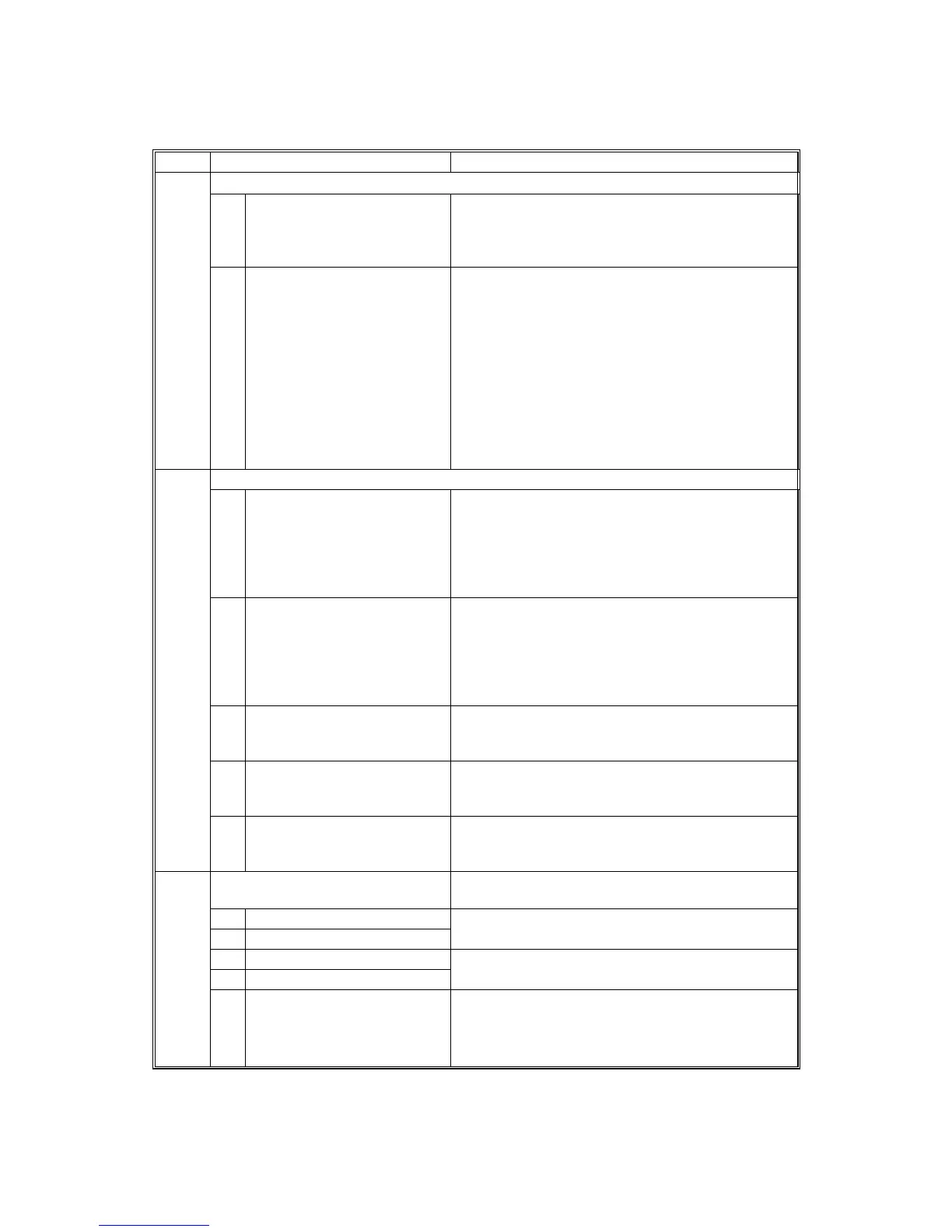

Printing Erase Margin Adjusts the leading edge (top), trailing edge

(bottom), left, and right margins.

01 Leading Edge

02 Trailing Edge

[0 ~ 9.0 / 3 / 0.1 mm step]

Specification: ±2 mm

03 Right Edge

04 Left Edge

[0 ~ 9.0 / 2 / 0.1 mm step]

Specification: ±1.5 mm

2101*

05 Trailing Edge – Back side Adjusts the trailing edge erase margin on the

reverse side of duplex prints.

[0 ~ 9.0 / 1.2 / 0.1 mm step]

Recommended: 2

±

1.5 mm

Loading...

Loading...