INSTALLATION

25

10 9 11

4

5

6

7

8

1

1

2

MI

RI

SE

13

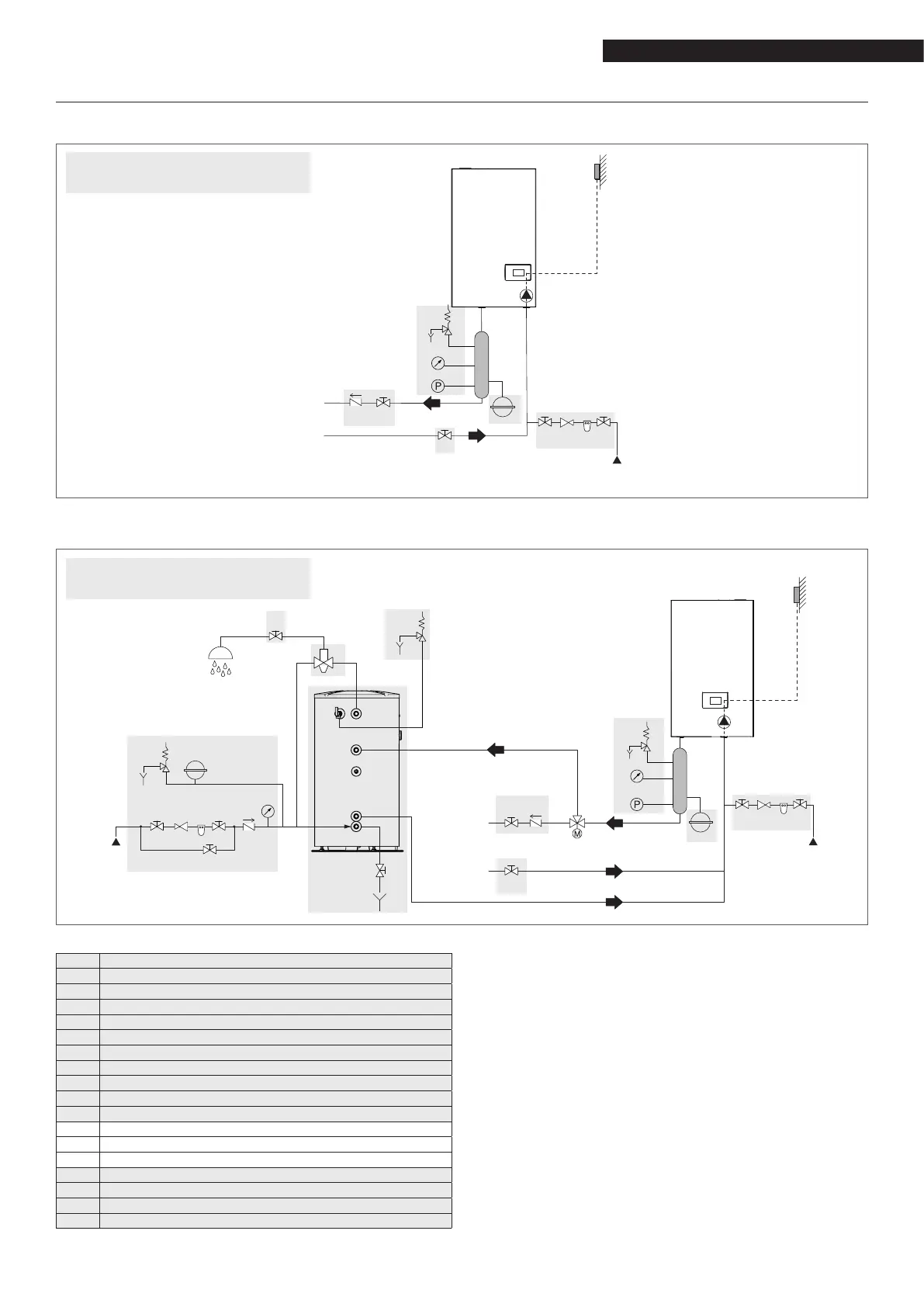

Layout 2: circuit with boiler directly connected to heating system and DHW tank (check that the pump discharge

head is sufcient to ensure adequate circulation)

12

21

1

4

1

1

5

6

1 10 9 1

1

2

6

5 4

3

11

5

6

7

8

10 9 11

7

SE

MI

RI

EAF

EAF

UAC

13

9

The DHW and heating circuits must be completed

with expansion vessels of adequate capacity and

correctly-sized safety valves. The discharge of the

safety valves and appliances must be connected to

a suitable collection and disposal system (see the

price list catalogue for compatible accessories).

9

The selection and installation of the system com-

ponents is the responsibility of the installer, who

must respect the standards of good practice and

current legislation.

9

Special supply/make-up water must be conditioned

using suitable treatment systems.

a

It is forbidden to operate the boiler and circulators

without water.

9

On Condexa HPR 35-45 models, the diverting valve

(12) can be installed in the boiler.

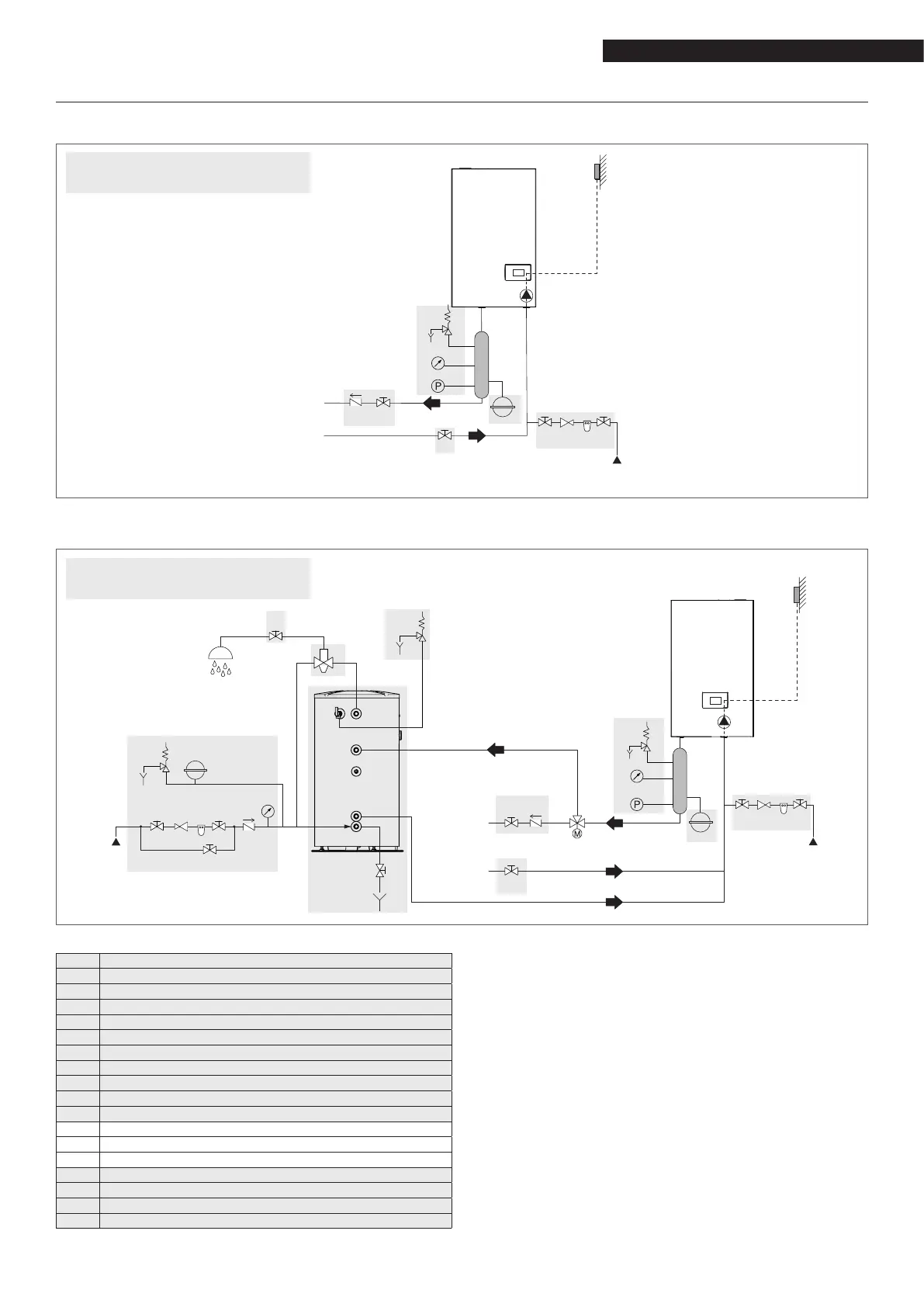

2.9 Schematic hydraulic systems

Layout 1: circuit with boiler directly connected to heating system (check that the pump discharge head is suf-

cient to ensure adequate circulation)

Components NOT managed

directly by the boiler

1 Disconnector valve

2 Non-return valve

3 Anti-burn mixer valve

4 Expansion vessel

5 Safety valve

6 Discharge

7 Pressure gauge

8 Minimum pressure switch

9 Softener filter

10 Pressure reducer

11 Storage tank

12 Diverting valve

13 Boiler circulator

SE Outdoor temperature sensor

MI High-temperature system delivery

RI High-temperature system return

EAF Cold water inlet

UAC DHW outlet

Components NOT managed

directly by the boiler

Loading...

Loading...