GENERAL REMARKS

5

1.3 Boiler description

Condexa HPR is a type C wall-hung condensing boiler

that can operate as follows:

CASE A:

heating only, without any external storage tank

connected. The boiler does not supply domestic hot

water.

CASE B:

heating only, with a thermostatically-controlled external

storage tank (accessory kit available upon request)

connected: in this condition, with every heat request

from the storage tank thermostat, the boiler supplies

hot water for the preparation of the domestic hot water.

CASE C:

Heating only, with the connection of an external storage

tank (accessory kit available upon request) managed by a

temperature probe, for domestic hot water preparation.

Connecting a boiler that we did not supply, make sure

that the probe used has the following characteristics: 10

kOhm at 25°C, B 3435 ±1%.

Depending on the ue gas exhaust accessory used, the

boiler is classied in categories B23P; B53P; C13,C13x;

C33,C33x; C43,C43x; C53,C53x; C63,C63x; C83,C83x;

C93,C93x.

In conguration B23P (when installed indoors), the ap-

pliance cannot be installed in bedrooms, bathrooms,

showers or where there are open replaces without a

proper air ow. The room where the boiler is installed

must have proper ventilation. Detailed requirements for

the installation of the ue, the gas piping and for venti-

lating the room, can be found in UNI 7129-7131.

This type of appliance can be installed indoors, within a

suitable room (central heating), as well as outdoors, in

a partially protected location (single boiler application).

Furthermore, with the aid of specic accessories, the

boiler can be installed in cascade conguration (up to 4

in-line boilers), or front-and-back conguration (up to

4 boilers - 2+2).

9

WARNING: it is impossible to create modular gener-

ators simultaneously containing thermal elements

with different heat input values. Only cascades,

with the same thermal element version on all the

thermal modules, can be created.

1.4 Safety devices

All the appliance functions are electronically controlled

by a board that has been type-approved for safety func-

tions.

Any malfunction results in the appliance being shut

down and the automatic closure of the gas valve.

The following are installed on the water circuit:

− Temperature probes on the delivery and return

lines, to continuously measure the temperature

difference (∆t) between input and output uid,

and allow the control to intervene.

− Pressure transducer with a minimum pressure

function, to inhibit burner ignition below 0.8 bar.

The following are installed on the combustion circuit:

− Ignition electrode and detection electrode

− Flue gas temperature probe

− Safety thermostat

− Gas valve

− The intervention of the safety devices indicates a

potentially hazardous boiler malfunction, there-

fore immediately contact the Technical Assistance

Service immediately. After a brief pause, it is pos-

sible to try to restart the appliance (see “3.1 Pre-

liminary checks”).

9

Safety devices must be replaced by the Technical

Assistance Centre, using only original parts. Refer

to the spare parts catalogue. After carrying out re-

pairs, check that the appliance is working properly.

a

The appliance must not be started, not even tem-

porarily, when safety devices are not working or

have been tampered with.

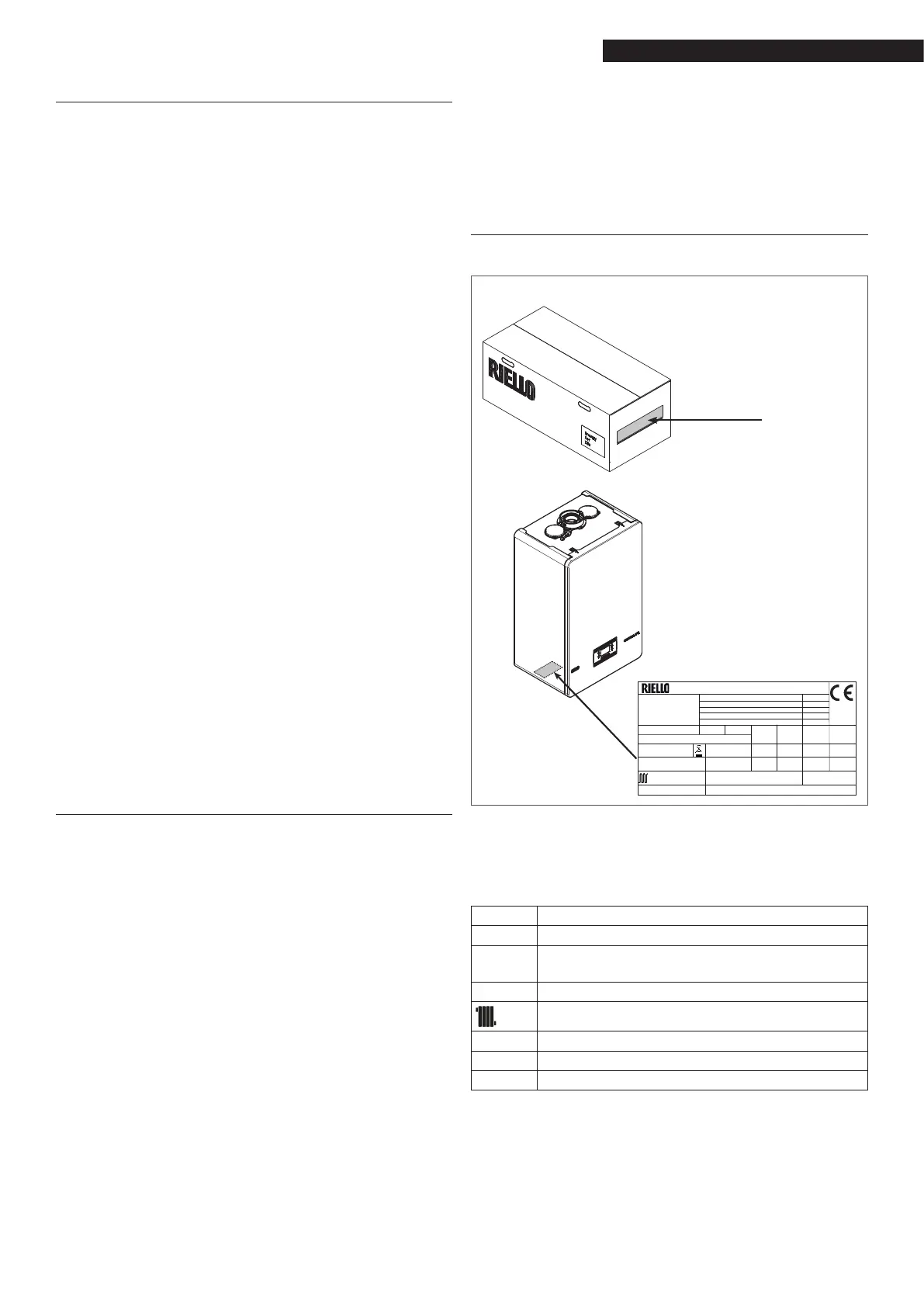

1.5 Identication

The

Condexa HPR boiler can be identied by:

Qn (Hi) =

0476/00

rial N.

00000000000

230 V ~ 50 Hz W

NOx: 6

Pms = bar T=

°

C

Pn =

B23P-B53P-C13-C33-C43-C53-C63-C83-C93

C13x-C33x-C43x-C53x-C63x-C83x-C93x

IPX5D

COD.

50-30

°

C

80-60

°

C

Qn

Qn

Qm

kW

kW

kW

kW

kW

CONDEXA HPR

Caldaia a condensazione

Condensing boiler

80-60

°

C

RIELLO S.p.A. - Via Ing. Pilade Riello, 7 - 37045 Legnago (Vr)

G20=20mbar G31=37mbar

II2H3P

- Data plate

It indicates the technical and performance data.

- Label on the packaging

9

Tampering, removal, lack of identication labels

or anything else which does not permit the safe

identication of the product, makes any installation

and maintenance operation difcult.

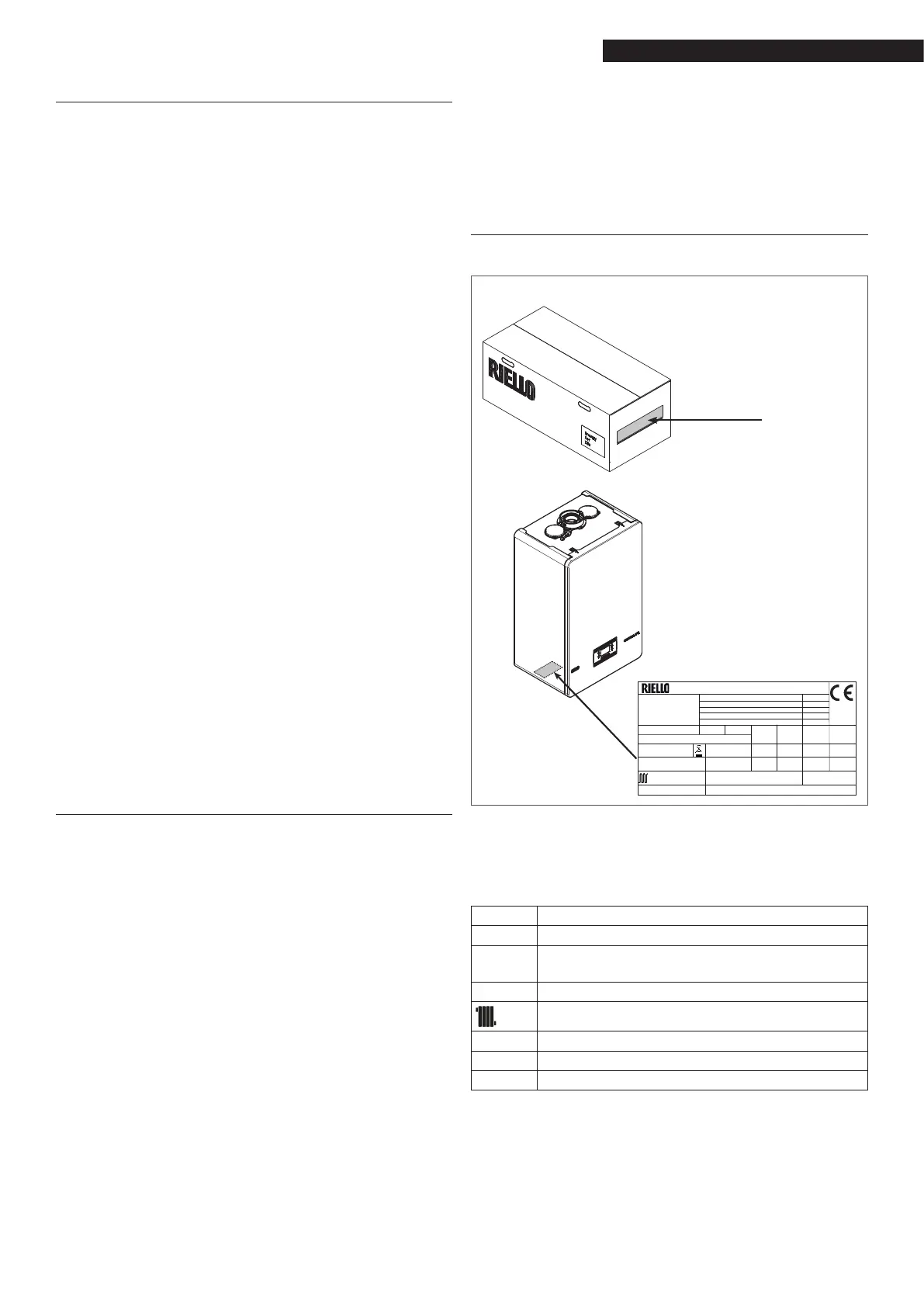

Qn Rated heat input (heating)

Qm Reduced heat input (heating)

Qn (Hi)

Rated heat input

(lower caloric value)

Pn Nominal heat output

Pms

Operation heating maximum pressure

T Temperature

IP Protection level

NOx NOx class

1

Loading...

Loading...