INSTALLATION

32

CONDEXA HPR 35-45

CONDEXA HPR 55-70

2.13

Flue gas exhaust and combustion air suction

To evacuate the combustion products, refer to UNI 7129-

7131. Always comply with the local regulations of the re

brigade and gas company, and with any possible mu-

nicipal regulations.

It is essential for ue gas evacuation and boiler combus-

tion air transfer that only original pipes are used (apart

from type C6, as long as it is certied), and that the con-

nection is made as explained in the instructions supplied

with the ue gas accessories.

A single ue can be con-

nected to several appliances provided that every appli-

ance is the condensing type.

9

9

Do not connect this appliance’s ue gas extrac-

tion pipes with those of other appliances, unless

this is specically authorised by the manufacturer.

Non-compliance with this precaution may cause a

build-up of carbon monoxide in the room where

the appliance is installed. This could jeopardise

people’s health and safety.

9

For more information on discharge pipes for ther-

mal modules connected in a cascade system, refer

to the price list catalogue and the instructions sup-

plied with the relative accessories.

9

Make sure the combustion (intake) air is not con-

taminated by:

− waxes/chlorinated detergents

− chemical products based on swimming pool

chlorine

− calcium chloride

− sodium chloride use to soften water

− refrigerant leaks

− paint or varnish removers

− hydrochloric acid/muriatic acid

− cements and glues

− anti-static softeners used in dryers

− chloride used for domestic or industrial applica-

tions as detergent, whitener or solvent

− adhesives used to x construction products etc.

9

To prevent contamination of the thermal module,

do not install suction line air intakes and ue gas

discharge pipes near:

− dry-cleaners/laundry rooms and factories

− swimming pools

− metal processing plants

− beauty parlours

− fridge repair shops

− photo-processing facilities

− body-shops

− plastics manufacturing plants

− furniture construction areas and plants.

9

The condensing appliances described in this man-

ual must be installed with ue gas pipes complying

with current legislation and purposely designed for

this specic use.

9

Check that pipes and joints are not damaged.

9

Joint seals must be made with materials that can

withstand the acidity of the condensate and the

temperatures of the ue gases.

9

Make sure the pipes are correctly assembled ac-

cording to the direction of the ue gases and the

descent of any possible condensate.

9

Inadequate or incorrectly sized ue gas pipes may

increase combustion noise, create condensate ex-

traction issues and negatively impact on the com-

bustion parameters.

9

Check that pipes are suitably far (min. 500 mm)

from ammable or heat-sensitive construction el-

ements.

9

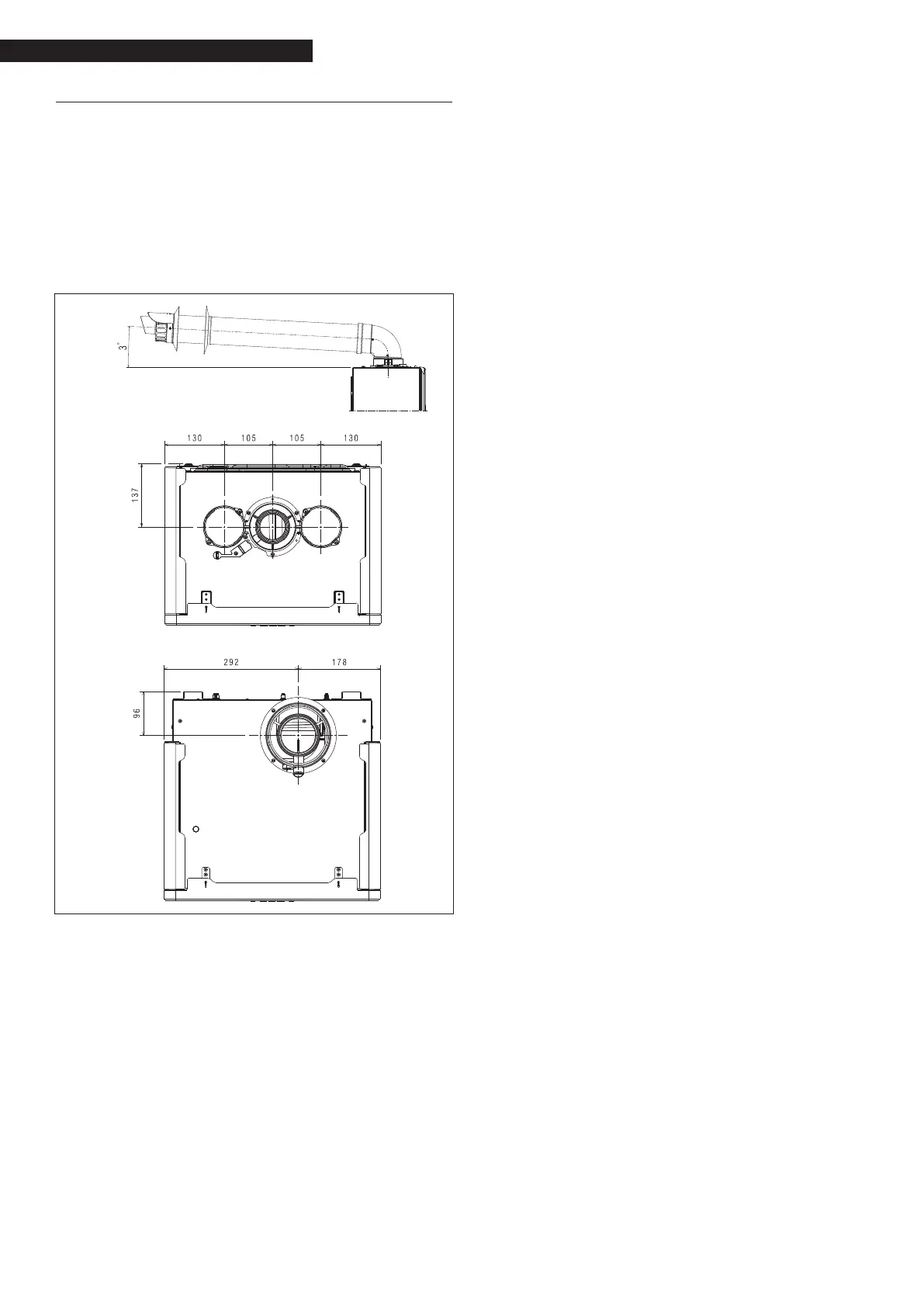

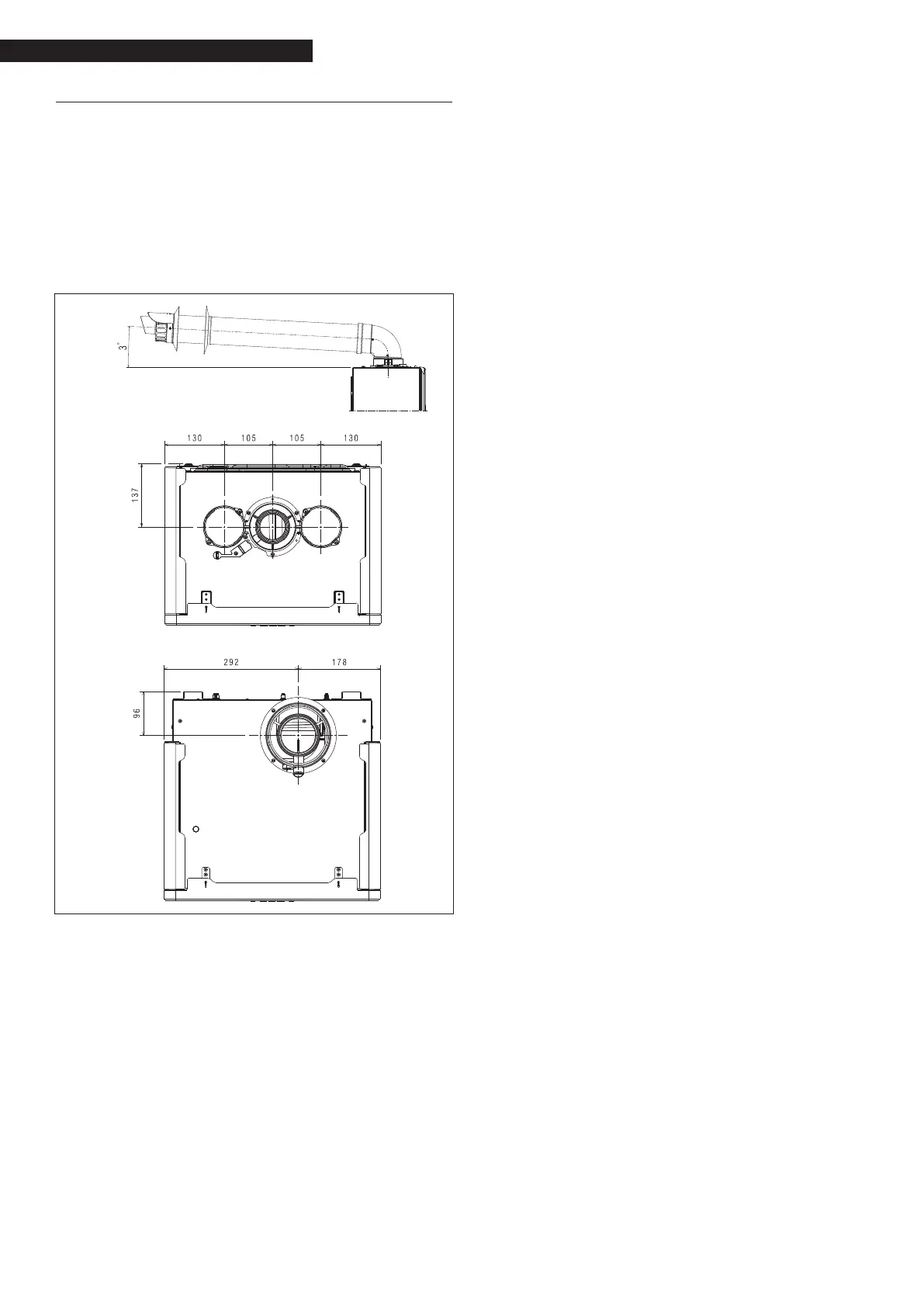

Check that no condensate builds up along the pipe.

To this end, the pipe should have a gradient of at

least 3° degrees towards the appliance if there is a

horizontal section. If the horizontal section or the

vertical one is more than 4 metre long, a drain-trap

for the condensate must be provided at the bottom

of the line. The height of the drain-trap must be at

least equal to “H” (see gure A page 34). The drain-

trap discharge must therefore be connected to the

sewerage system.

a

It is forbidden to obstruct or choke the ue gas pipe,

or the combustion air suction pipe (if installed).

a

It is forbidden to use pipes not purposely designed

for this function, as the contact with the conden-

sate would quickly damage them.

Installing the ue gas pipes

− Position the discharge pipe so the connection is

fully up against the ue gas turret of the boiler.

Loading...

Loading...